Inner curved plane cam rolling bearing radial plunger pump

A flat cam and inner curve technology, which is applied in pumps, multi-cylinder pumps, machines/engines, etc., can solve the problems of large friction and wear, high decibel noise, and aggravated friction and wear between the plunger and the elliptical inner curved cam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

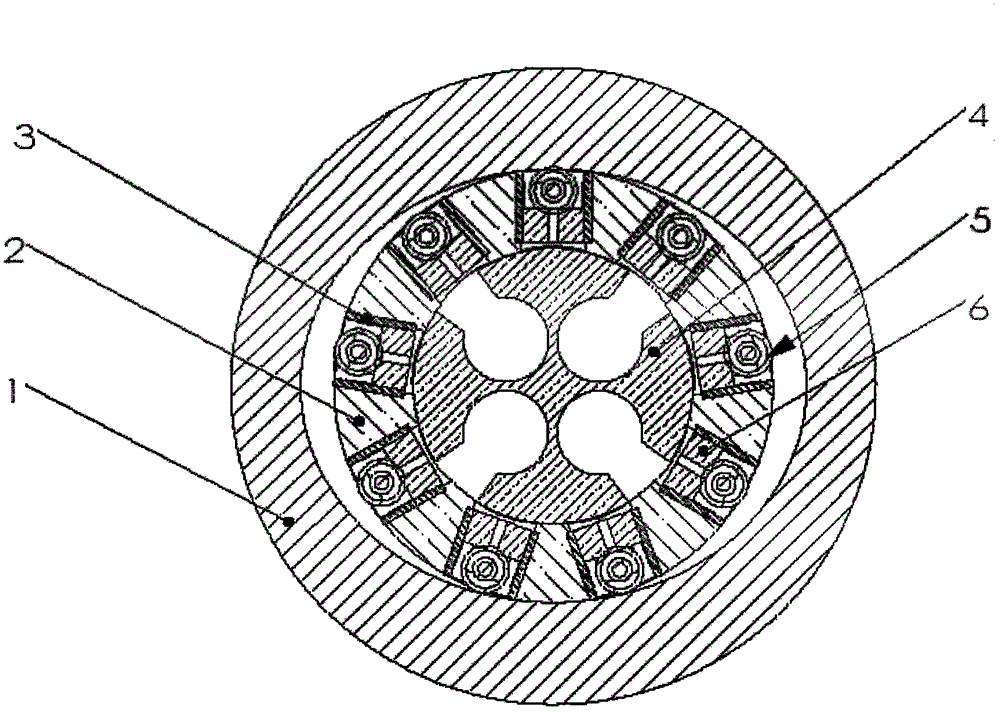

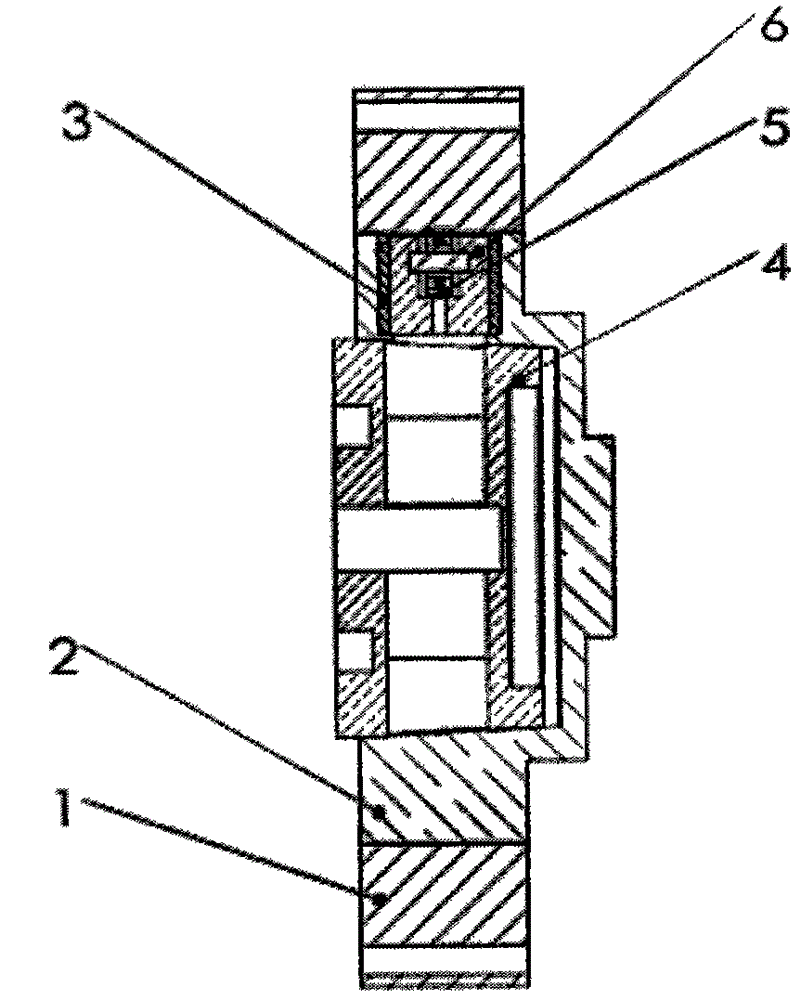

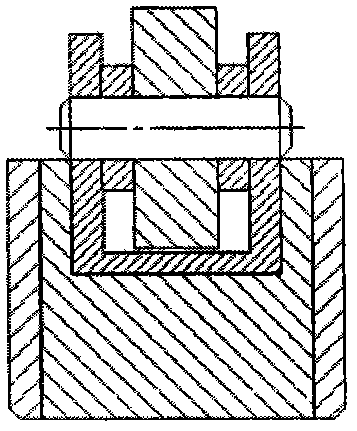

[0009] combine figure 1 , the curved track inside the cam of the stator [1] is elliptical, the cylinder liner [3] is evenly distributed on the rotor [2] according to its circumference, and each combined plunger (bearing rolling mechanism [5], plunger [6]) corresponds to A cylinder liner [3], the flow distribution shaft [4] is located on the axis line of the rotor [2].

[0010] The motor drives the rotor [2] to rotate, and the rotor [2] drives the combined plunger (bearing rolling mechanism [5], plunger [6]) in the cylinder liner [3] to rotate. When the rotational speed reaches a certain value, under the joint action of inertial force, hydraulic pressure and stator reaction force, the outer bearing of the bearing rolling mechanism [5] of the combined plunger (bearing rolling mechanism [5], plunger [6]) The circle moves in an elliptical circle along the inner curved track of the stator [1] cam, and the plunger [6] moves back and forth in the cylinder liner. When the bearing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com