Device and method for detecting oil well dynamic liquid level depth based on audio-acoustic wave electro-acoustic system

A dynamic liquid level and audio technology, applied in construction and other directions, can solve the problems of difficult wellhead coupling, difficult infrasound source design, ground-level sound wave interference, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

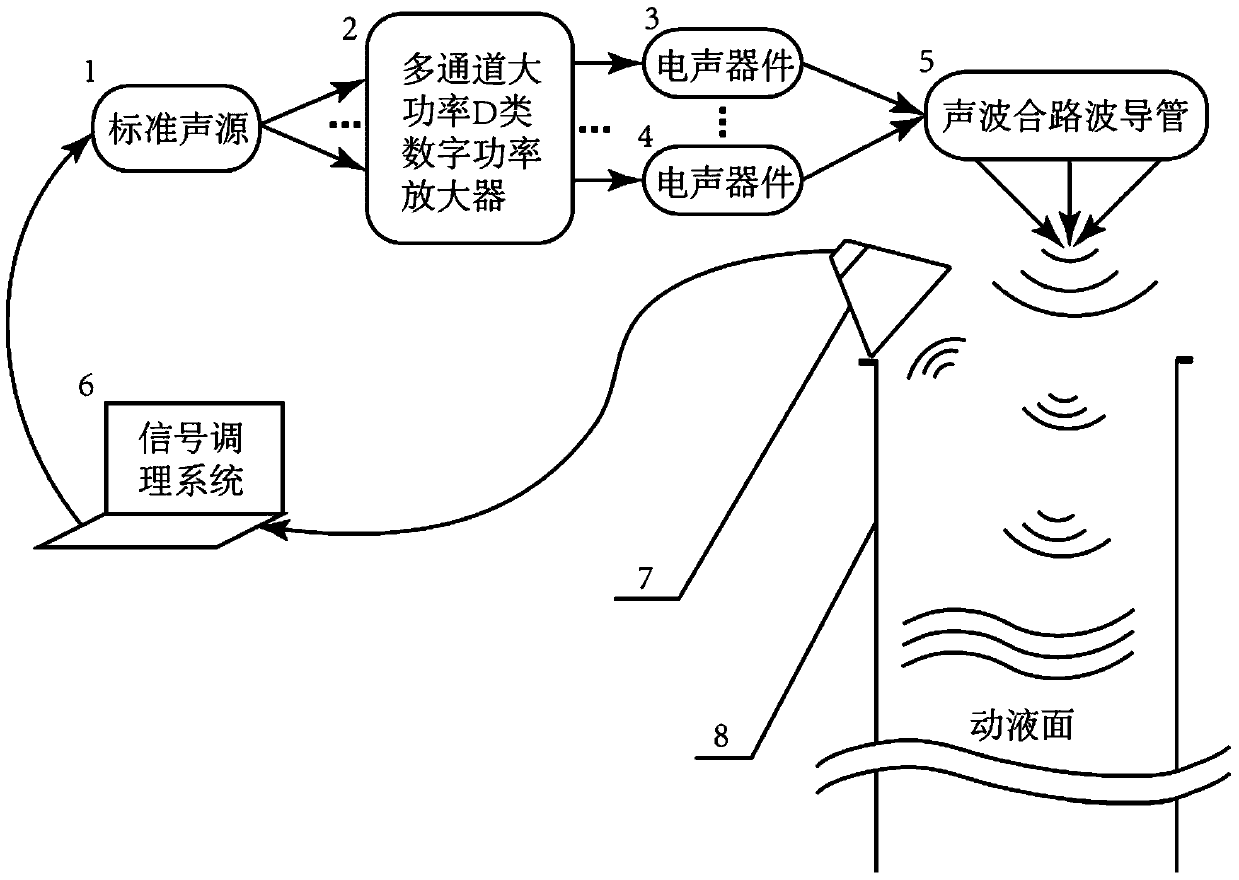

[0033] Attached below figure 1 The present invention is further described.

[0034] Concrete embodiment of the present invention and its implementation process are as follows:

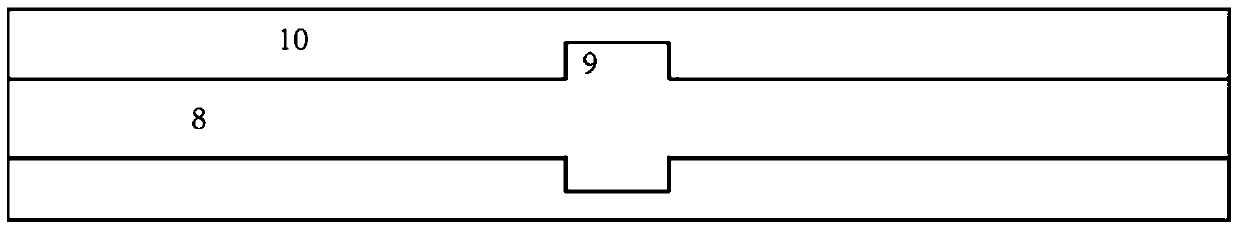

[0035] Such as figure 1 As shown, the implementation device includes a signal conditioning system 6 placed on the ground, a standard sound source 1, a multi-channel high-power Class D digital power amplifier 2, a first electroacoustic device 3, a second electroacoustic device 4, and an acoustic wave combining waveguide The tube 5 and the wellhead acoustic wave receiving device 7, the standard sound source 1 is respectively connected with the first electro-acoustic device 3 and the second electro-acoustic device 4 through a multi-channel high-power class D digital power amplifier 2, and the dual-channel power amplifier 2 has two independent The channels respectively process the two signals sent by the standard sound source 1, and the first electroacoustic device 3 and the second electroacoustic device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com