Automatically ventilated fire doors

A ventilated, fire-resistant door technology, applied in the field of fire-resistant doors, can solve problems such as lack of ventilation function and adverse effects of living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

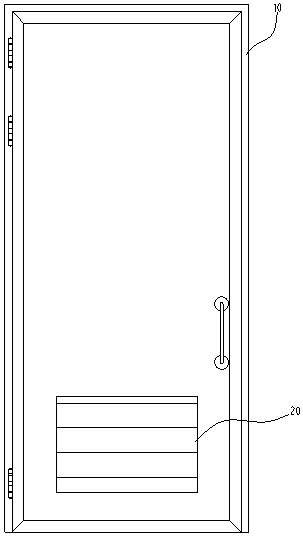

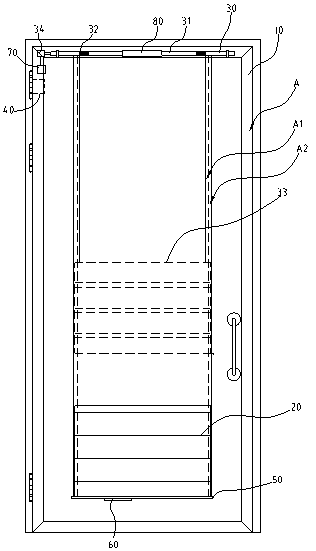

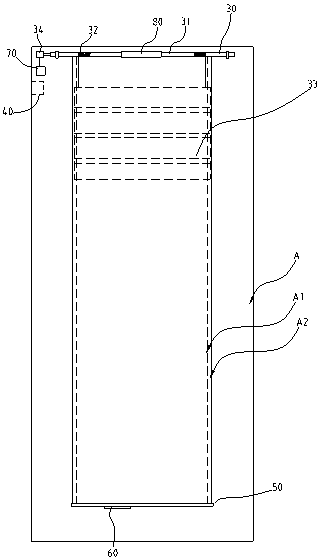

[0015] Referring to the accompanying drawings, an automatic ventilating fire door includes a door body 10, a shutter 20 is provided on the door body 10, a temperature sensor 40 is provided inside the door body 10, and an automatic fireproof shutter unit is installed above the shutter 20 inside the door body 10. 30, the lower edge of the shutter 20 is located directly below the automatic fire shutter unit 30 to set a seat plate 50, and a gravity sensor 60 is set on the seat plate 50;

[0016] The automatic fire shutter unit 30 includes a reel 31, on which a rope 32 is wound, and the lower end of the rope 32 is fixedly connected with a steel fire shutter 33, and a motor 34 is arranged at the end of the reel 31, and the motor 34 is connected to the The controller 70 is connected, and the middle section of the reel 31 is fixed with a pressure sensor 80 around the reel 31. When the steel fireproof shutter 33 is located on the seat plate 50, the steel fireproof shutter 33 completely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com