A Rotary Gas Distribution Structure of Ring-type Series Cylinder Groups

A rotary gas distribution and cylinder bank technology, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems that the valve structure cannot realize intake and exhaust, etc., and achieve low vibration and noise and fast response speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

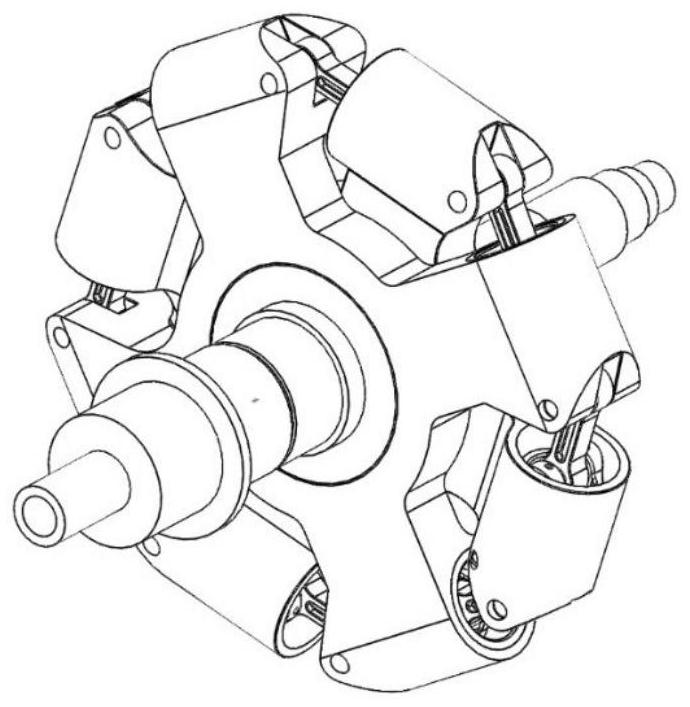

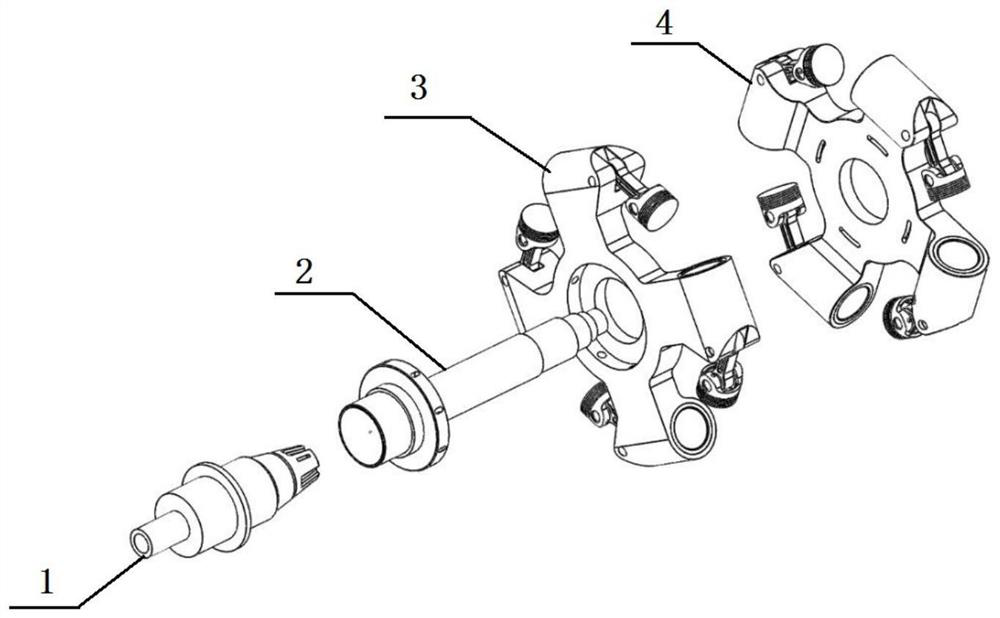

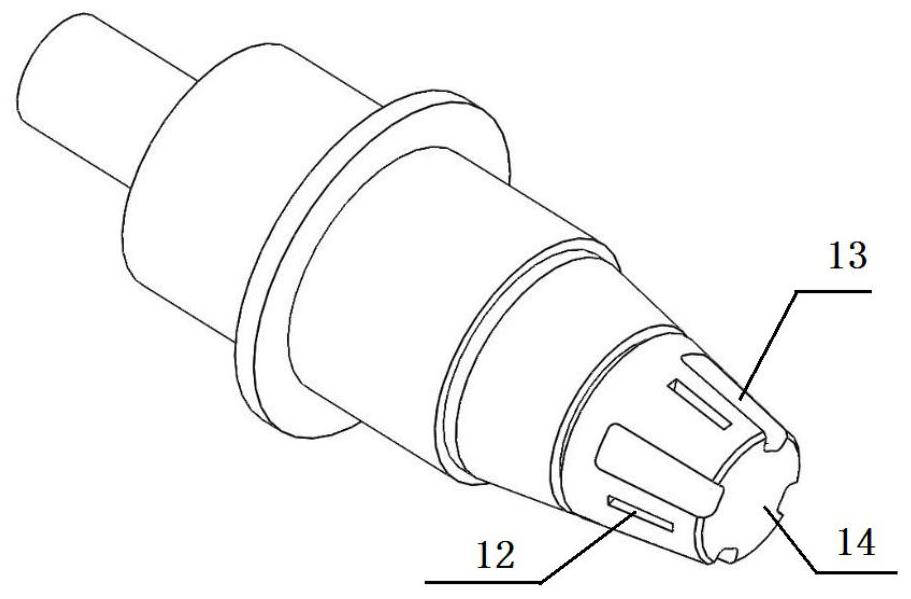

[0029] like Figure 1 to Figure 8 As shown, the present invention discloses a rotary gas distribution structure of an annular series cylinder group, comprising a gas distribution shaft 1, a rotary gas distribution bushing 2, a main rotor 3, a secondary rotor 4, a gas distribution shaft 1 and a rotary gas distribution bushing 2 Coaxial nesting installation, the main rotor 3 and the auxiliary rotor 4 are combined and sleeved on the rotary gas distribution shaft sleeve 2, the gas distribution shaft 1 is provided with an air supply channel 11, and the rotary gas distribution shaft sleeve 2 is provided with an exhaust channel 21 , a plurality of air inlets 12 and a plurality of exhaust ports 13 are arranged along the circumferential direction of the peripheral wall at the junction of the gas distribution shaft 1 and the rotating gas distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com