Double-raising pallet fork truck

A technology for stacking trucks and pallets, applied in the field of stacking trucks, can solve the problems of high cost and complex structure, and achieve the effects of low cost, safe operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

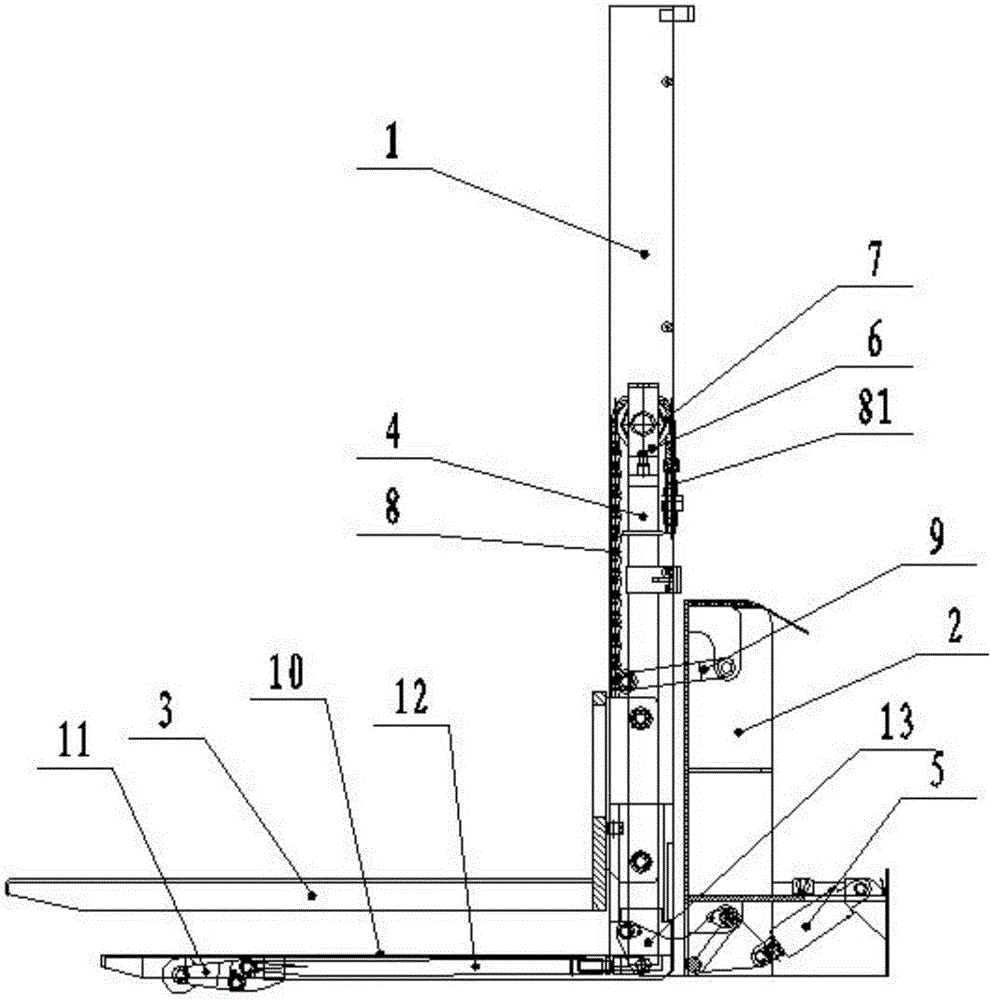

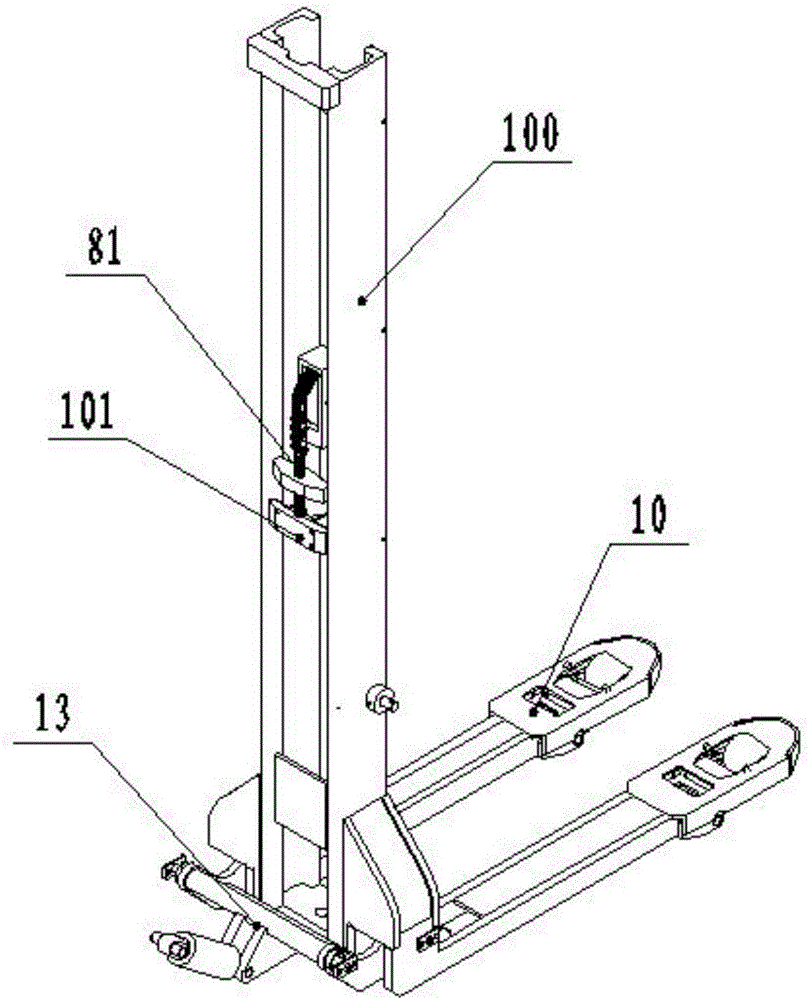

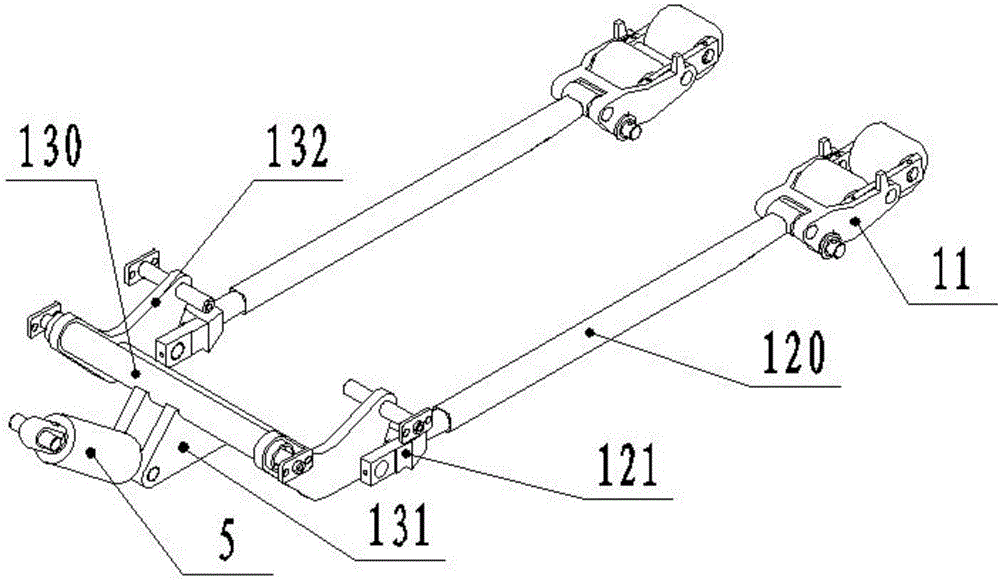

[0022] Double lift pallet stacker, such as Figure 1-Figure 5 As shown, it includes a front frame 1, a rear frame 2, and a fork frame 3 that can slide up and down along the front frame 1, and also includes a straight oil cylinder 4 fixed on the front frame 1 and arranged longitudinally, and the piston of the straight oil cylinder 4 The end of the rod is fixed with a sprocket 7, specifically the end of the piston rod of the straight oil cylinder 4 is fixed with a sprocket seat 6, the sprocket 7 is connected to the sprocket seat 6 through a pin shaft, and a single chain 8 is arranged on the sprocket 7 , one end of the chain 8 is fixed on the front frame 1, and the other end is fixed on the fork frame 3; the front frame 1 includes a door frame, and the door frame includes two uprights 100 and a beam 101 connected between the two uprights 100 , the end connected to the front frame 1 on the chain 8 is connected with a long screw 81, the chain 8 is connected to the beam 101 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com