An Eccentric Control Mechanism and Realization Method of a Pitch Adjustable Straight Wing Propeller

A technology of eccentric control and thrusters, applied in the direction of rotary propellers, etc., can solve the problems of limiting the practicality of straight-wing propellers, increasing the weight of the turntable, and large installation space, etc., achieving excellent maneuverability, reducing the total weight, reducing Effect of small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

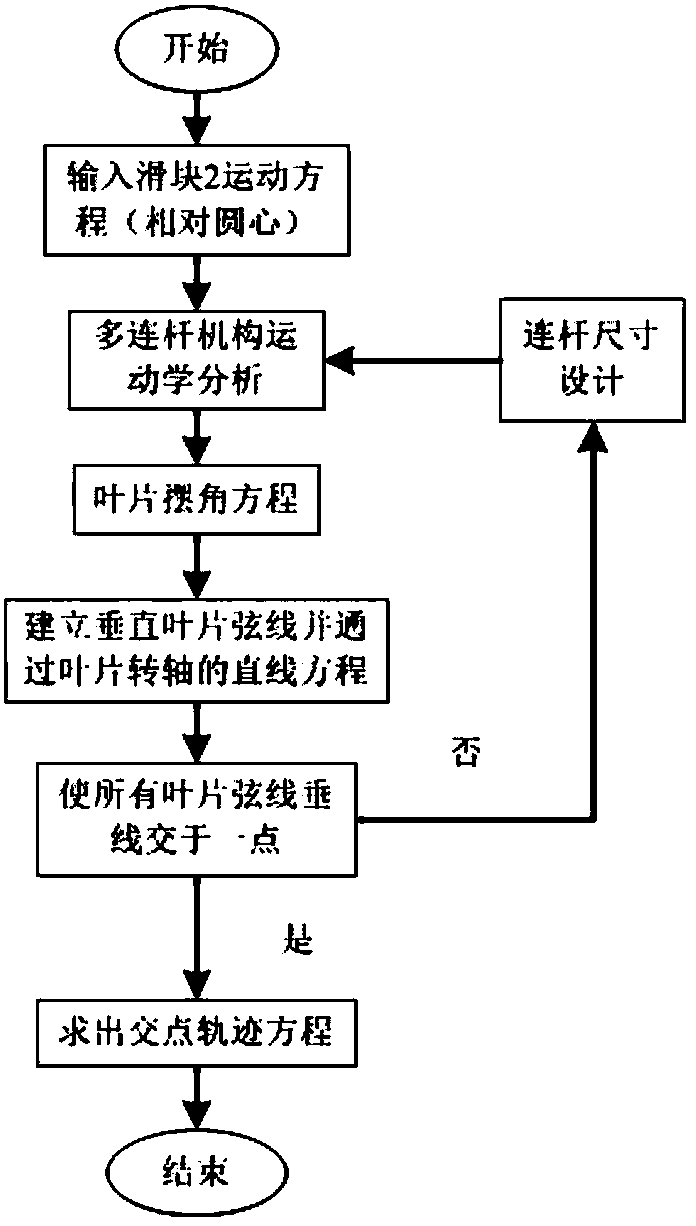

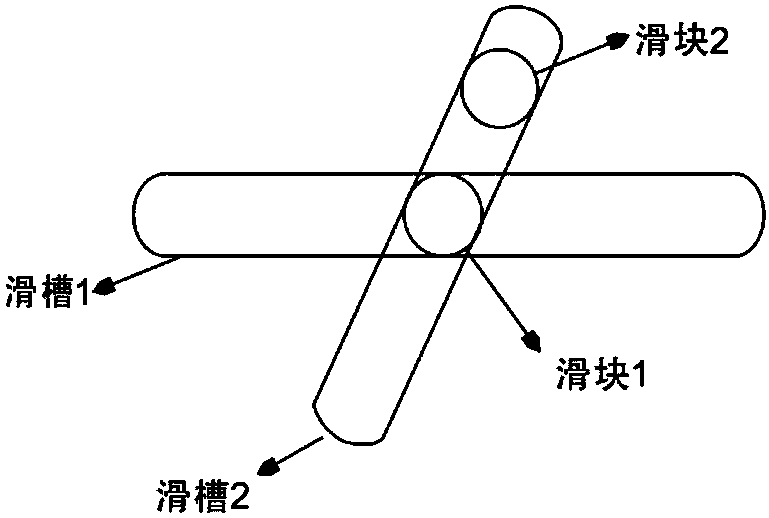

[0077] In order to more fully understand the features of the invention and its applicability to engineering practice, the present invention is aimed at verifying the eccentric control mechanism of the double-slider linkage of the 5-bladed straight-wing propeller, and simplifies the mechanism. Figure 11 shown. Due to the blade and connecting rod l 7 The angle between them is a fixed value such as Image 6 shown. Therefore, find the control point and link l 7 functional relationship between them.

[0078] Due to the symmetry of the structure, only the linkage mechanism of one blade is analyzed, and the analytical solution of the swing angle of each rod of the multi-link mechanism with respect to the rod length can be obtained:

[0079]

[0080]

[0081]

[0082]

[0083]

[0084]

[0085] where θ 2 =θ 3 ,

[0086] A=l 5 -l 1 cosθ 1

[0087] B=-l 1 sinθ 1

[0088]

[0089] D=l 8 -l 45 cosθ 45

[0090] E=-l 45 sinθ 45

[0091] F=D 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com