Fin stabilizer directly driven by servo motor

A technology of servo motor and servo electric cylinder, which is applied in the field of ship anti-rolling, can solve the problems of high noise, low efficiency, heat generation, etc., and achieve the effect of simple parameter setting, simple device structure and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and implementation.

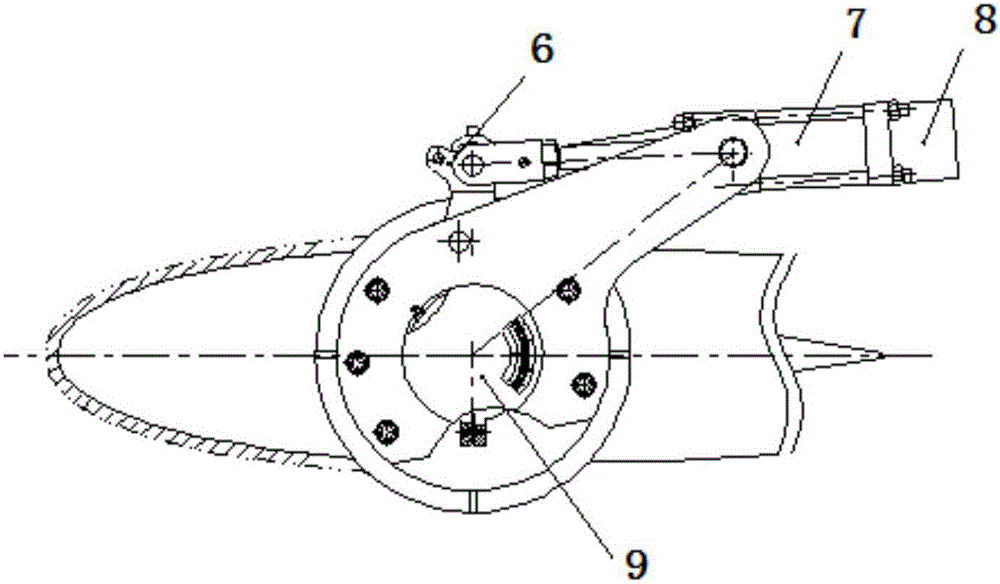

[0016] In the fin stabilizer device of the present invention, its fin rotating drive system adopts the electric servo system of "servo motor + screw screw" to replace the traditional hydraulic servo system. design.

[0017] The control principle of the fin stabilizer device of the present invention is consistent with the traditional fin stabilizer except that the driving part adopts the present invention, and its principle block diagram is as follows figure 1 shown. During the working process, the lift force of seawater acting on the fins is transmitted to the actuator through the fin shaft, and then transmitted to the hull to generate a righting moment against wave disturbance and realize the anti-rolling function.

[0018] The invention is mainly composed of a fin, an executive mechanism, a screw screw transmission mechanism, a servo motor, a controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com