Delivery spray jig for robot extrusion casting

A technology of squeeze casting and robot, which is applied in the field of squeeze casting, can solve the problems of ingenious structural design, unsatisfactory spray effect, and lack of pick-up function, etc., and achieves clever structural design, easy installation and daily maintenance, and favorable The effect of widely promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

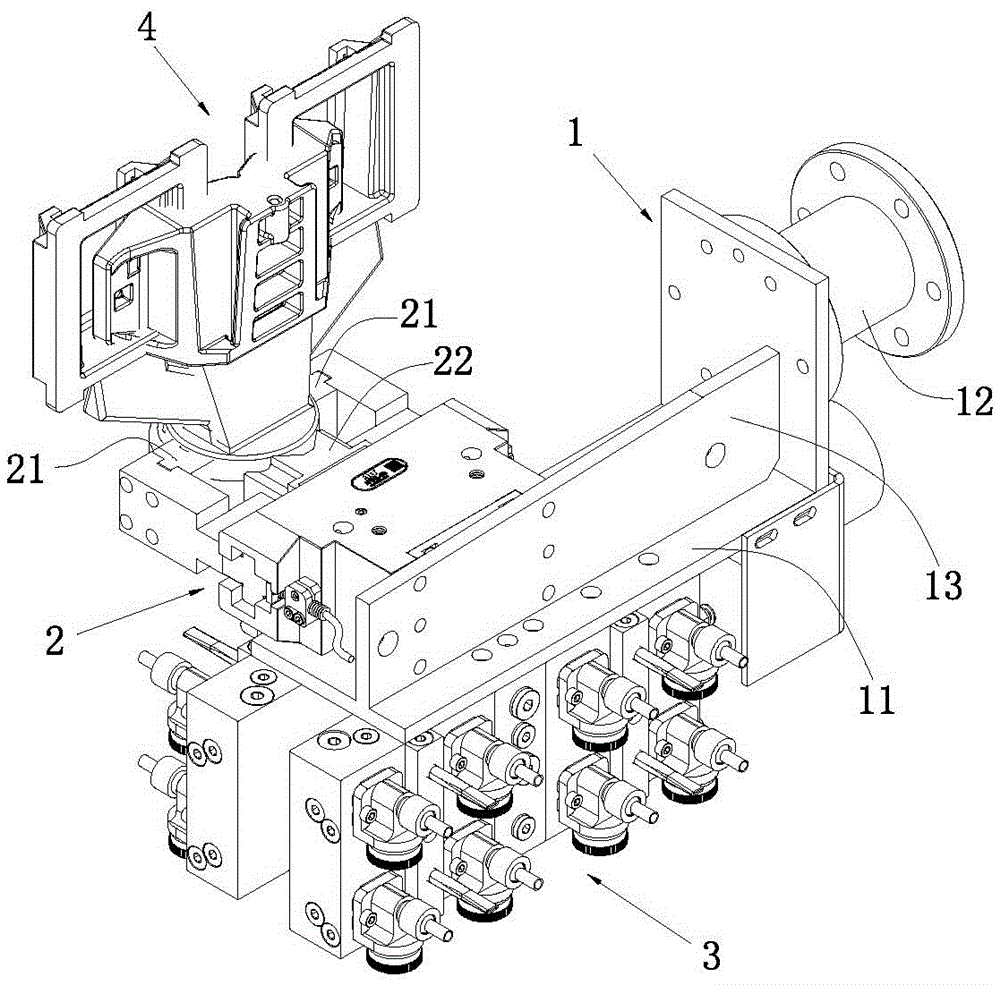

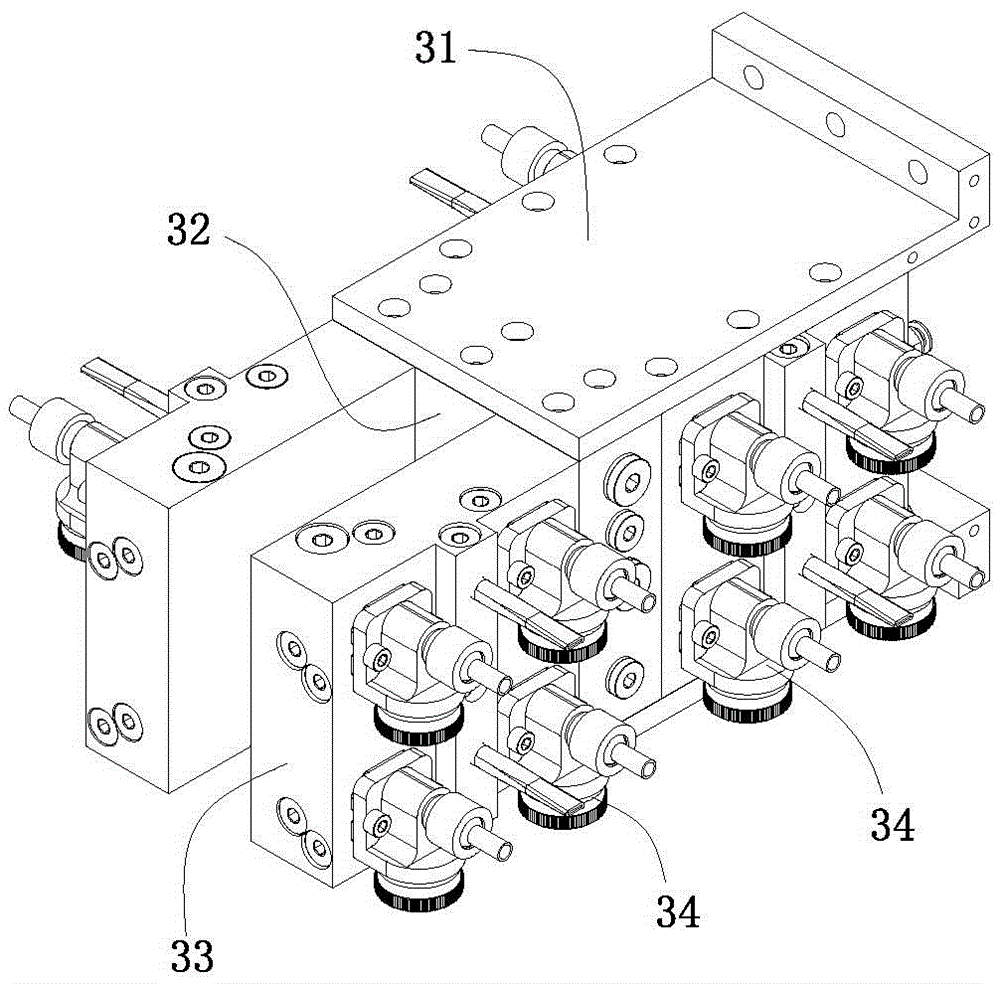

[0017] Examples, see figure 1 and figure 2 , a robot squeeze casting extraction spray fixture provided in this embodiment includes a connecting seat 1, a pneumatic gripper 2 and a multi-head spraying module 3, and the connecting seat 1 includes a mounting plate 11 and is arranged on the mounting plate 1. The robot arm installation head 12 at one end of the board 11, the upper surface of the installation board 11 is vertically provided with a limit plate 13, the multi-head spray module 3 is arranged on the lower surface of the installation board 11, and the pneumatic gripper 2 is arranged on the installation board 11, and the rear end surface of the pneumatic gripper 2 presses against the limiting plate 13.

[0018] see figure 1 , the two clamping parts of the pneumatic gripper 2 are respectively provided with a movable fixture 21 adapted to the outline of the workpiece 4 to be clamped, and the position between the two symmetrical gripping parts is located between the pneuma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com