Steel die splitting and assembling device for pouring

A mold clamping device and steel mold technology, which is applied in the direction of casting mold components, casting molding equipment, casting molds, etc., can solve problems such as high temperature, burns, and high labor intensity, so as to improve accuracy, reduce hidden dangers of safety accidents, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

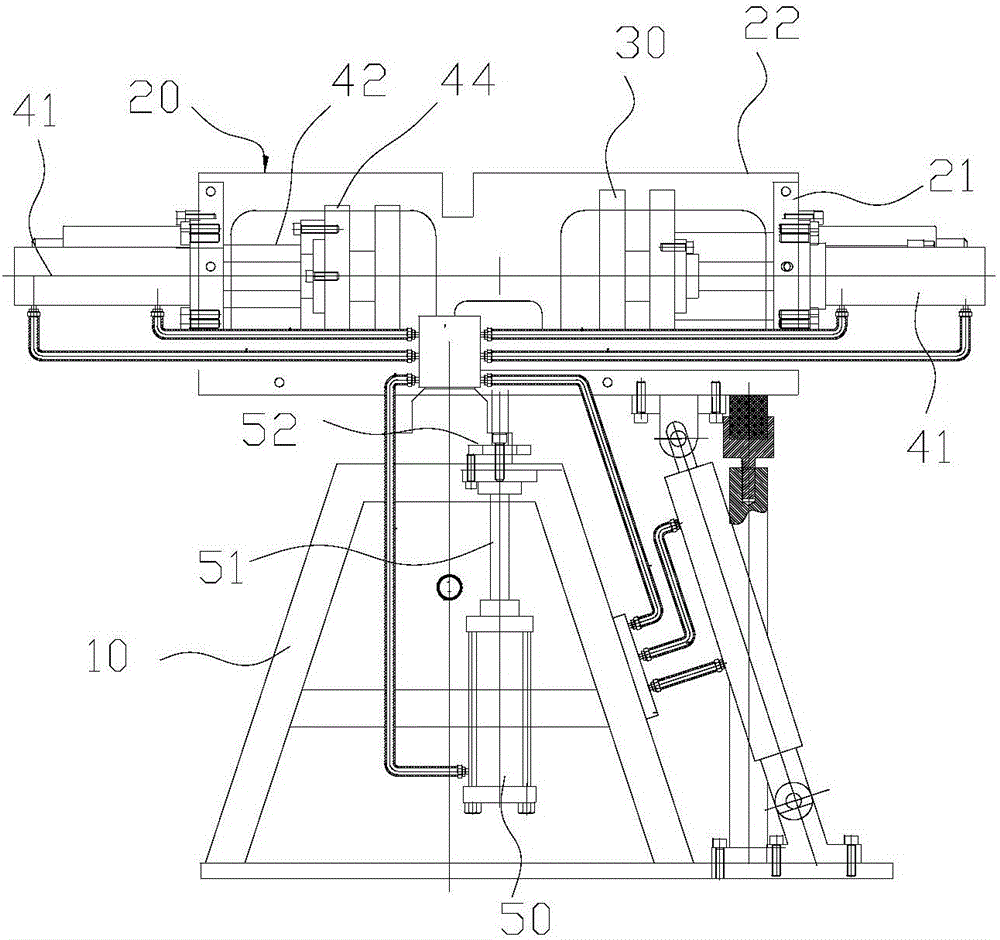

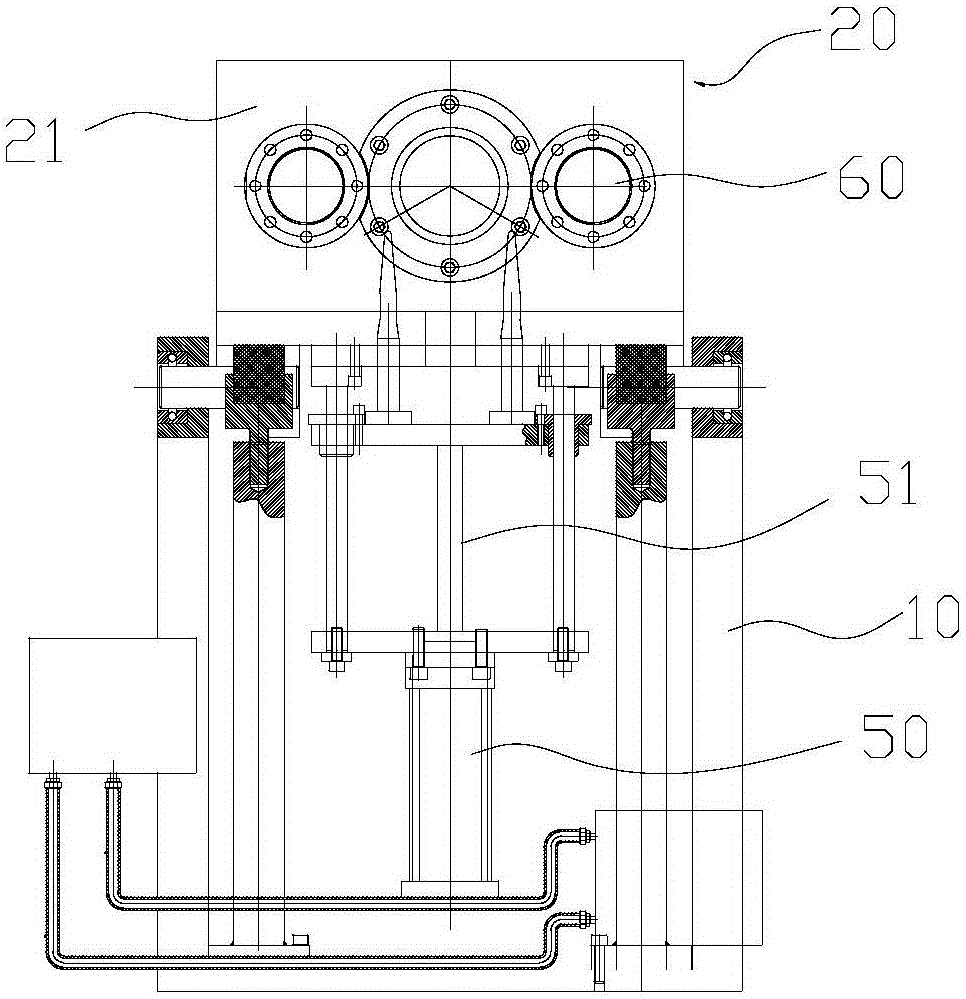

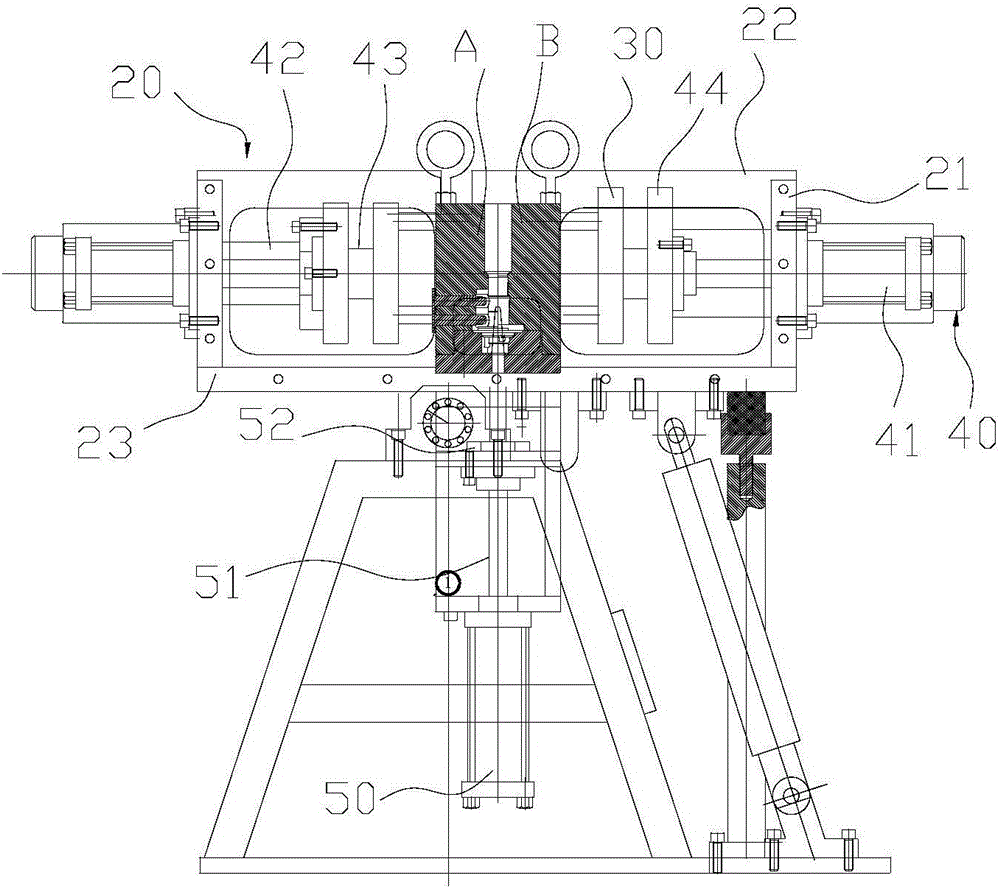

[0010] combine figure 1 , 2 3. The splitting and clamping device of the casting steel mold includes a frame 20 provided on the base 10, the frame 20 is provided with a mold connecting plate 30 connected with the split unit constituting the mold, and the mold connecting plate 30 is connected with the mobile clamping The moving clamping mechanism drives the mold connecting plate 30 together with the split unit of the mold to perform mold clamping or mold splitting, and an insulating unit is arranged between the mold connecting plate 30 and the moving clamping mechanism.

[0011] combine image 3 , Connect the split units A and B of the mold to the mold connecting plate 30 respectively. The state shown in the figure is that the split units A and B are in the state of clamping the mold, and a lifting ring is provided on the mold to facilitate the lifting operation when changing the mold. . The heat insulation unit is arranged between the die connecting plate 30 and the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com