Manufacturing method of automatic efficient multi-level sand washing and screening equipment

A manufacturing method and high-efficiency technology, applied in chemical instruments and methods, sieves, solid separation, etc., can solve the problems of large amount of sand, labor and time-consuming, etc., and achieve the equipment with simple structure, easy operation and high screening efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

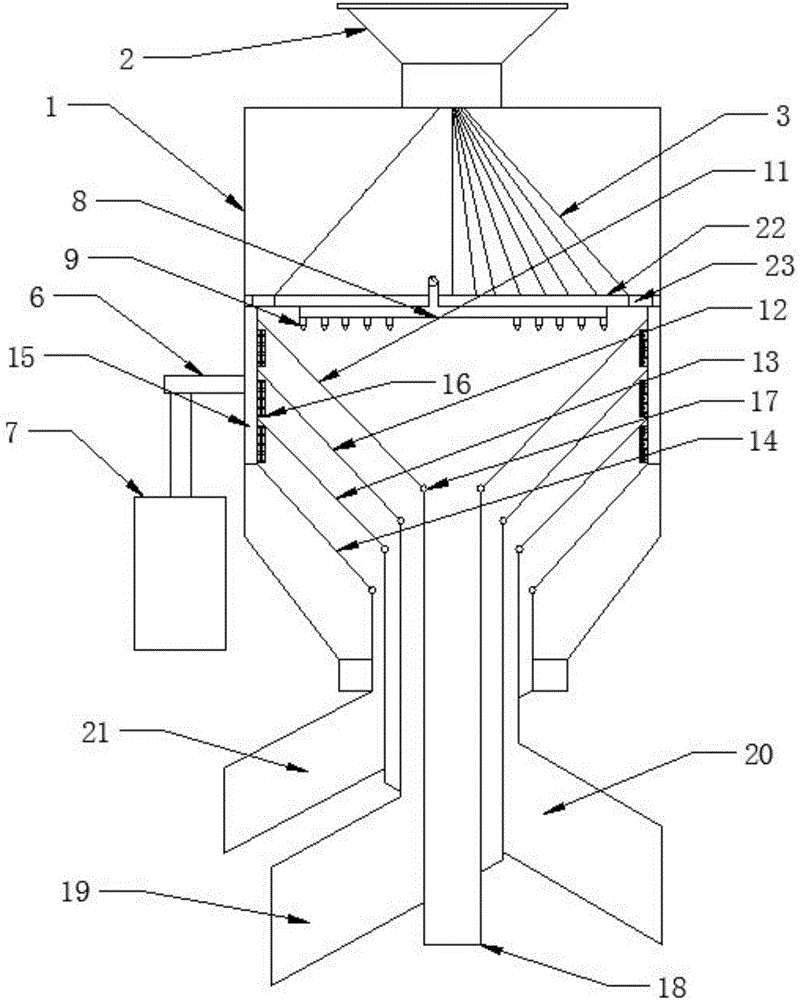

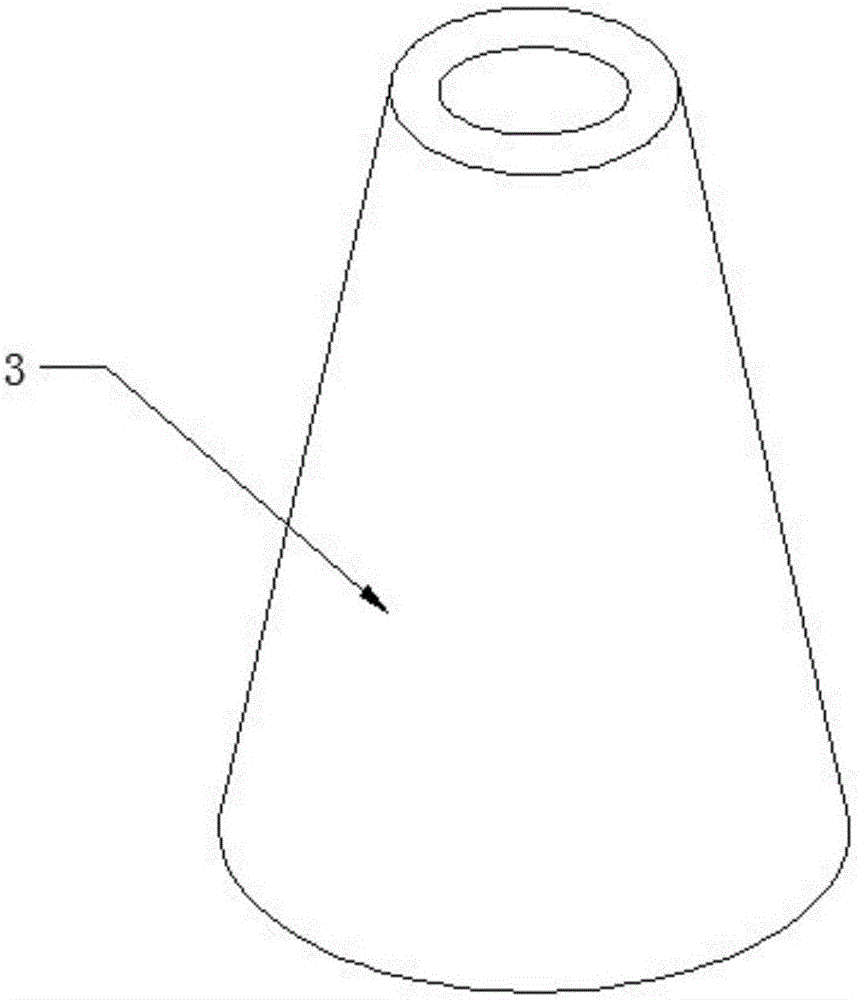

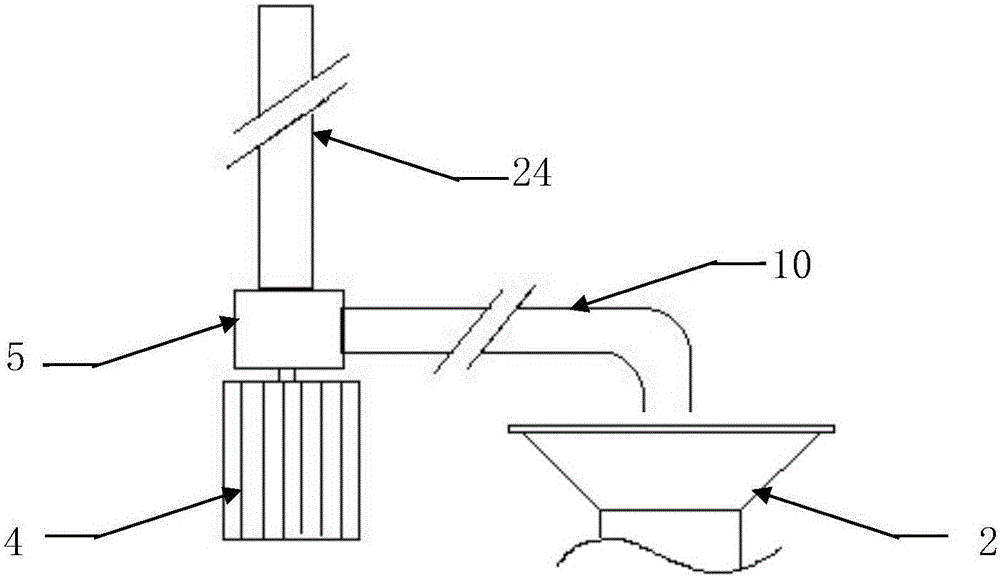

[0025] Example 1: See Figure 1~3 , an automatic high-efficiency multi-stage sand washing and screening equipment, including a cylinder body 1, a material distribution seat 22, a cylinder 7 and a sand suction pump 5, a feed hopper 2 is installed in the middle of the top of the cylinder body 1, and the material distribution seat 22 is installed on the cylinder body 1, on the inner wall, between the material distribution seat 22 and the feed hopper 2, there is a conical cylinder material distribution plate 3, and the material distribution seat 22 is provided with a plurality of discharge openings 23 located on the outside of the material distribution plate 3, and the cylinder body 1 A sliding connecting plate 15 is connected to the inner wall; the bottom of the cylinder body 1 is provided with a first sand outlet cylinder 18, a second sand outlet cylinder 19, a third sand outlet cylinder 20 and a fourth sand outlet cylinder 21 sequentially from inside to outside, And the heights...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com