Efficient and energy-saving unprocessed grain peeling, degerming, polishing and screening multi-use machine

A high-efficiency energy-saving, multi-purpose machine technology, applied in the field of machinery, can solve the problems of only 50-90 kg per hour, food waste, high cost, etc., achieve significant economic and social benefits, reduce production costs, and produce low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

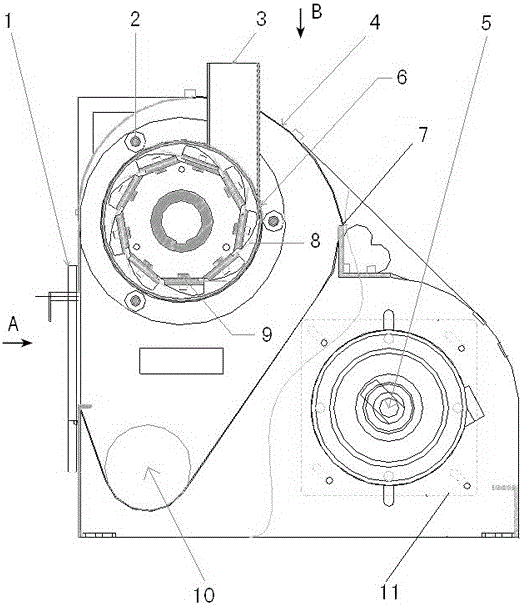

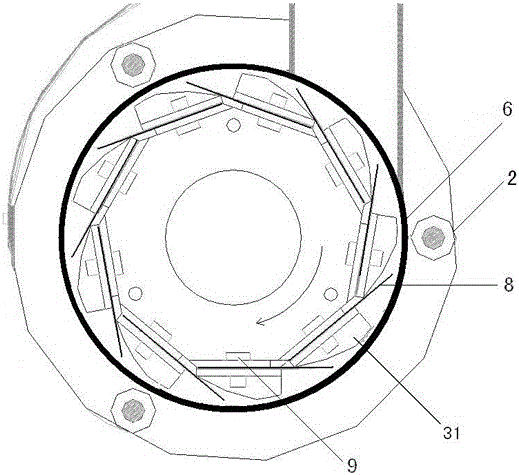

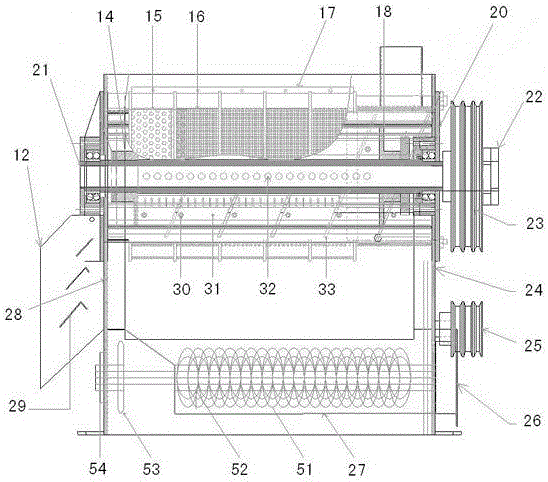

[0021] like figure 1 As shown in -8, (with the direction of material running as the front and rear) high-efficiency and energy-saving raw grain peeling, germination, polishing and screening multi-purpose machine, including the casing (including the end covers at both ends, that is, the end cover 20 at the feed end and the end cover 36 at the discharge end), Feeding hopper 3, feeding chamber 38, peeling chamber 16, discharging chamber 34, motor 5, the right side of peeling chamber 16 is feeding chamber 38, and the left side is discharging chamber 34, forming a complete feeding, taking off and discharging process. Passage; the lower opening of the feed hopper 3 leads to the peeling chamber 16, and the peeling chamber 16 is provided with a main shaft 21, the main shaft 21 is horizontally arranged on the end plate of the peeling chamber through a bearing, and the belt pulley 23 at the outer end of the main shaft 21 is connected to the motor power wheel by a belt; the main shaft Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com