A device for breaking stubble, furrowing and fertilizing for no-tillage seeder

A technology of fertilization device and seeder, which is applied in fertilizer and seeding equipment, excavation/covering of trenches, application, etc., can solve the problems of inability to close seed trenches, exposed seeds, hanging grass, congestion, etc. The effect of improving the quality of sowing and improving the quality of soil cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

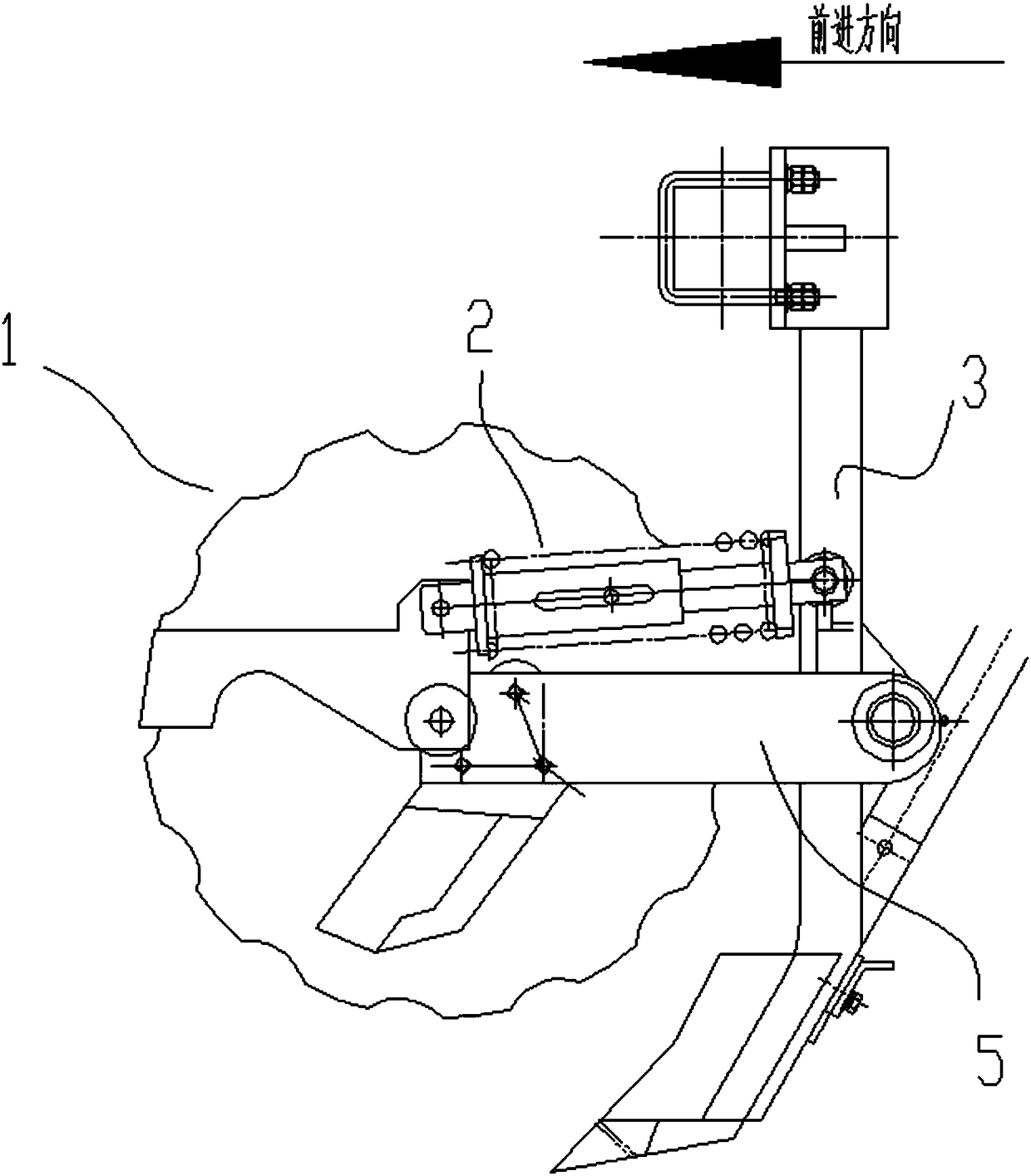

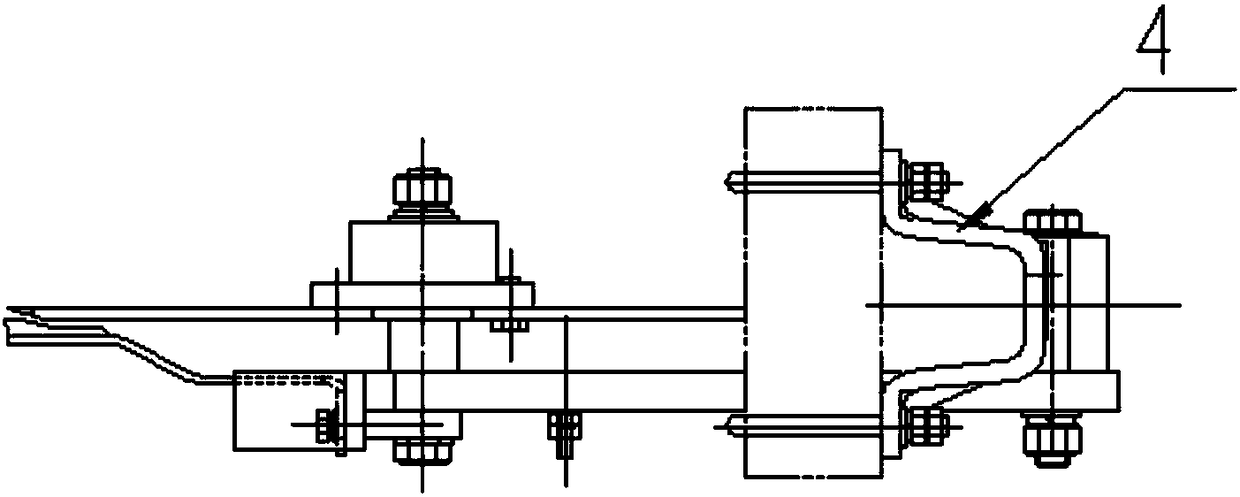

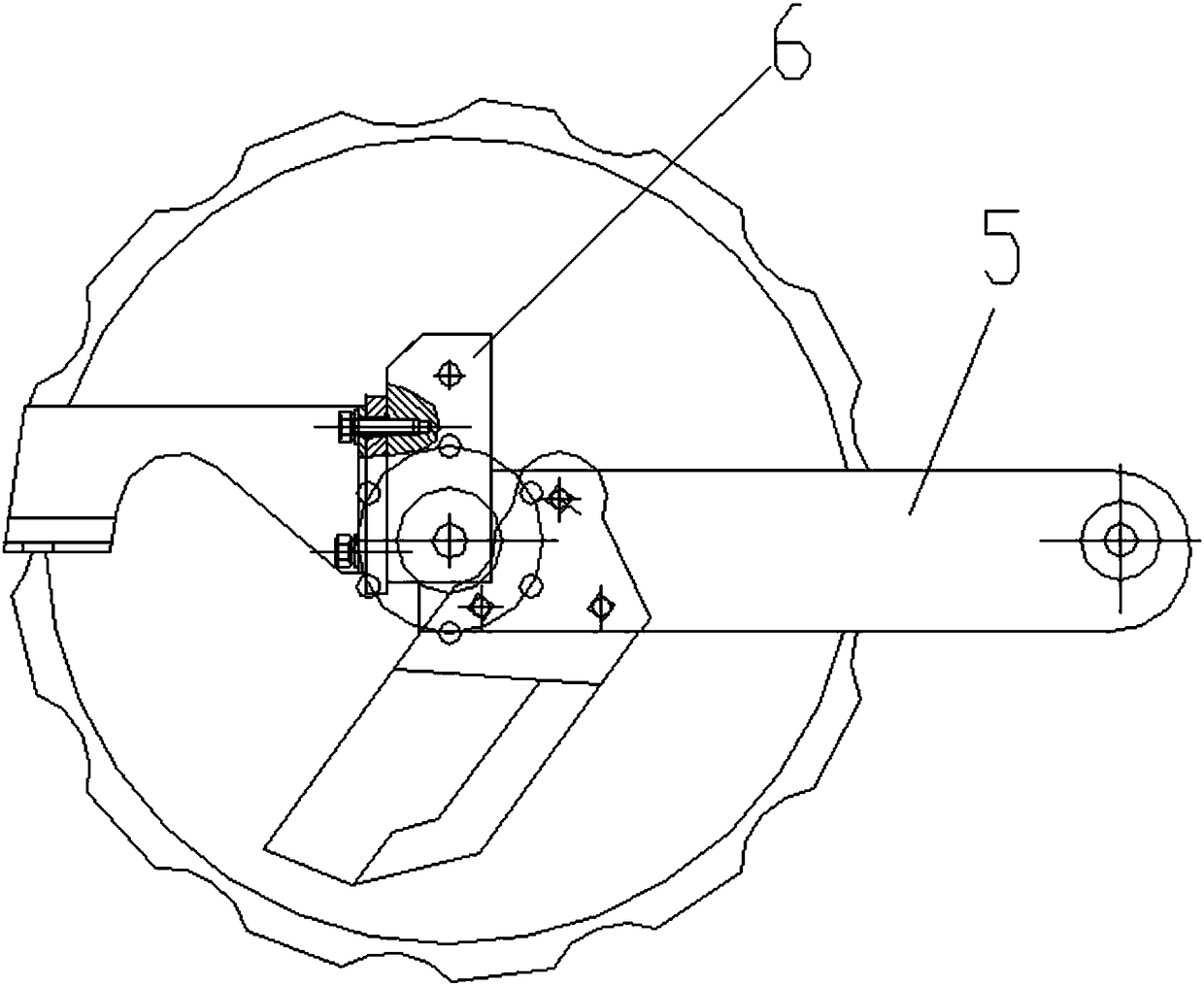

[0029] see Figure 1-Figure 7 , a stubble-breaking, ditching and fertilizing device for a no-tillage planter, comprising a ditch opener 3, characterized in that: it also includes a stubble-breaking assembly 1, a spring seat assembly 2, a connecting arm 5, and a suspension arm 6. The stubble assembly 1 is arranged directly in front of the ditch opener 3; the stubble breaking assembly 1 includes a stubble breaking disc part 101, and the disc part 101 has a sharp blade, which can cut the land when it rotates, and the ground surface Straw and weeds are cut off; the ditch opener 3 is used to ditch along the kerf; the central shaft of the stubble breaking assembly 1 is hinged to the connecting arm 5, and the connecting arm 5 is hinged to the main girder of the ditch opener; The front and rear ends of the spring seat assembly 2 are respectively hinged with the suspension arm 6 and the ditch opener 3, and the suspension arm 6 is hinged with the central shaft of the stubble breaking as...

Embodiment 2

[0036] see Figure 8-9 , on the basis of Embodiment 1, the device for breaking stubble, ditching and fertilizing the no-tillage seeder also includes a ditch edge loosening part 7, and the ditch edge loosening part 7 includes a pair of top-to-bottom inwardly inclined A ditch edge loosening disc part 701 that is symmetrical on both sides with the stubble breaking disc part 101 as the center, and the ditch edge loosening disc part 701 is corresponding to the position of the ditch soil, and the ditch soil is cut when rotating; The ditch edge loosening parts 7 are fixedly arranged directly behind the ditch opener 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com