Diaphragm and micro sounder provided with the diaphragm

A pattern and folding ring technology, applied in the field of micro sound generators, can solve problems such as difficulty in meeting the requirements of high sound quality of electronic equipment, inability to truly restore sound signals, creases or collapses of diaphragms, etc. Poor collapse, low distortion, high sound quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

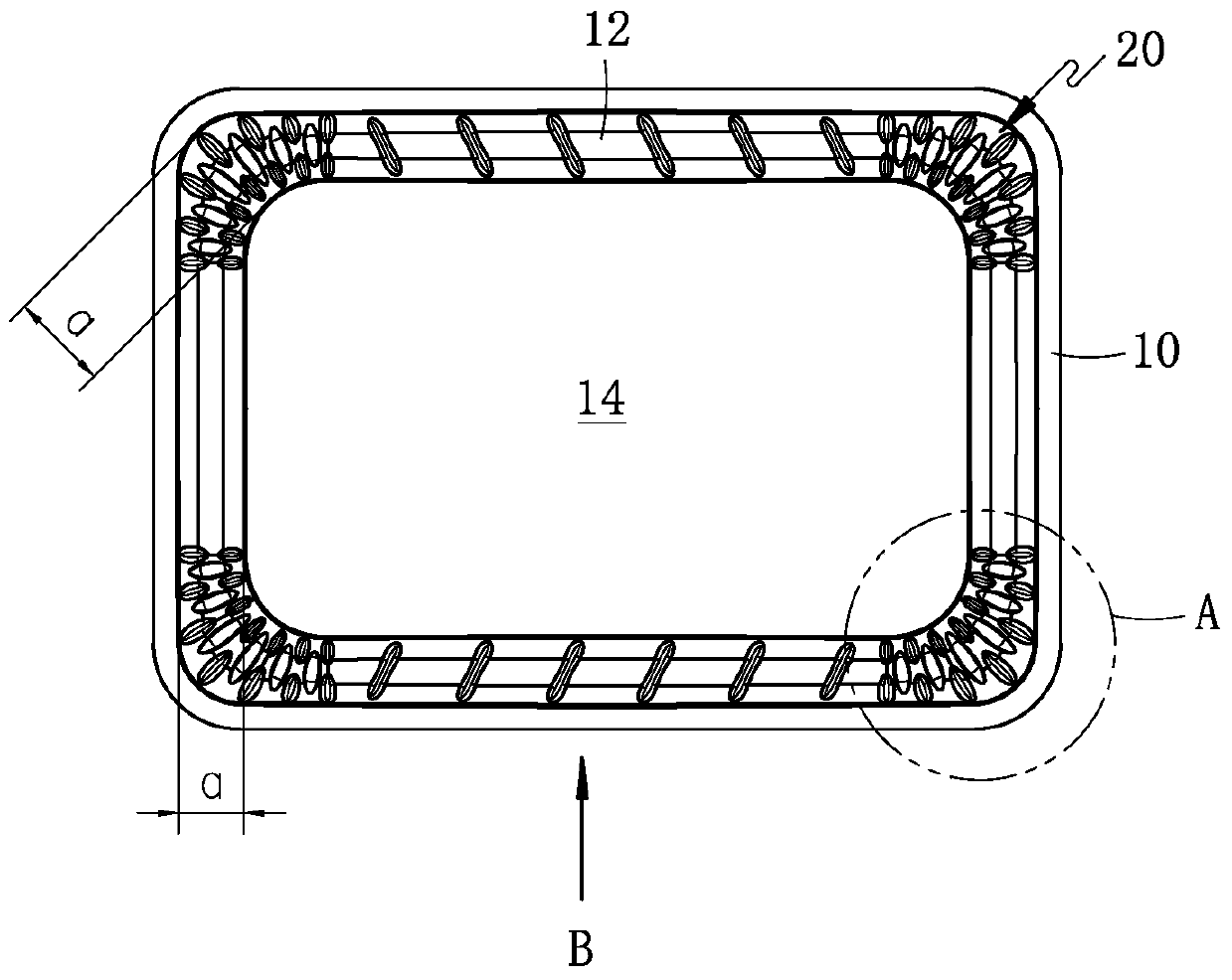

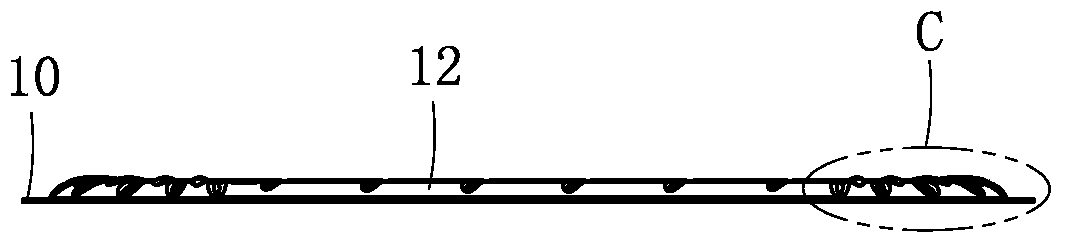

[0030] Such as figure 1 with image 3 As shown together, a vibrating membrane has a rectangular structure, including a spherical top 14 , a ring portion 12 and an edge portion 10 sequentially connected as one from the inside to the outside. The ring portion 12 is a rectangular ring-shaped structure, including two parallel four straight segments, and four curved segments connected between two adjacent straight segments, and the four curved segments constitute the ring portion 12. four corners. Patterns 20 are distributed on the ring portion 12 . In this embodiment, the patterns 20 are preferably concentrated and distributed at the four corners of the ring portion 12 , that is, four curved sections.

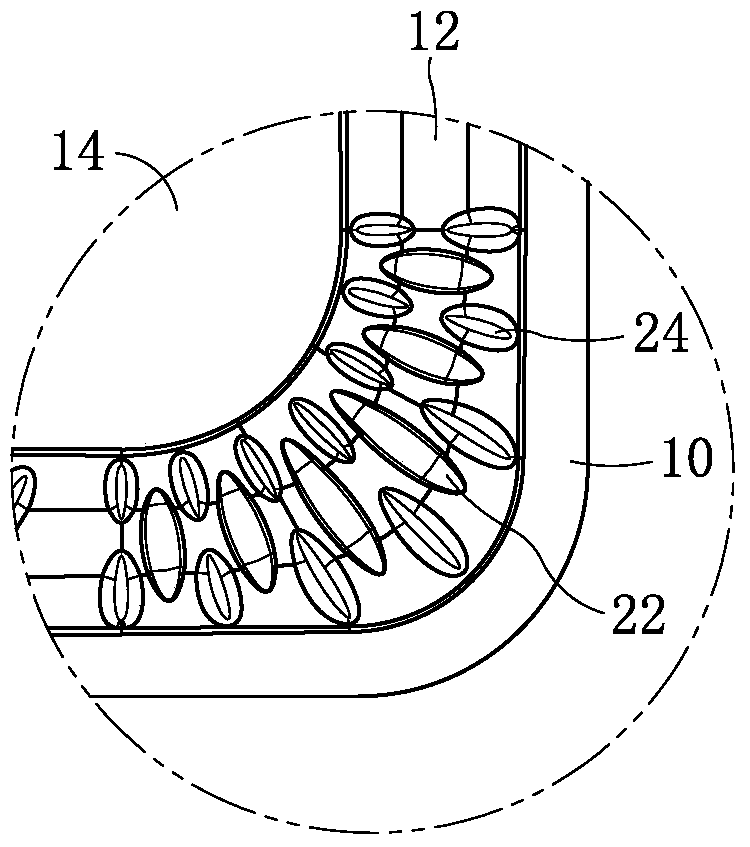

[0031] Such as figure 2 with Figure 4 Commonly shown, the pattern 20 at each corner includes two patterns with opposite convex directions, one is the convex pattern 22 whose convex direction is the same as that of the fold ring portion 20, and the other is the convex pattern ...

Embodiment 2

[0041] A miniature sound generator includes a vibrating system and a magnetic circuit system. The vibrating system includes a vibrating membrane and a voice coil combined together. The vibrating membrane is the vibrating membrane described in Embodiment 1.

[0042] Since the micro-speaker of the present invention adopts the diaphragm described in Embodiment 1, the distortion is greatly reduced, the sound reproduction effect is good, and the sound quality is high, which can meet people's requirements for high sound quality of electronic equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com