Novel alternating-current and direct-current hybrid tractive power supply system

A traction power supply system, AC and DC hybrid technology, applied in the direction of irreversible AC power input conversion to DC power output, single AC network with different frequencies, conversion equipment that can be converted to DC without intermediate conversion, etc., can solve the problem of The possibility of failure increases, the equipment cannot work normally, and the equipment manufacturing cost is increased, so as to achieve the effects of reducing harmonic content, saving investment costs and engineering quantities, and reducing floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

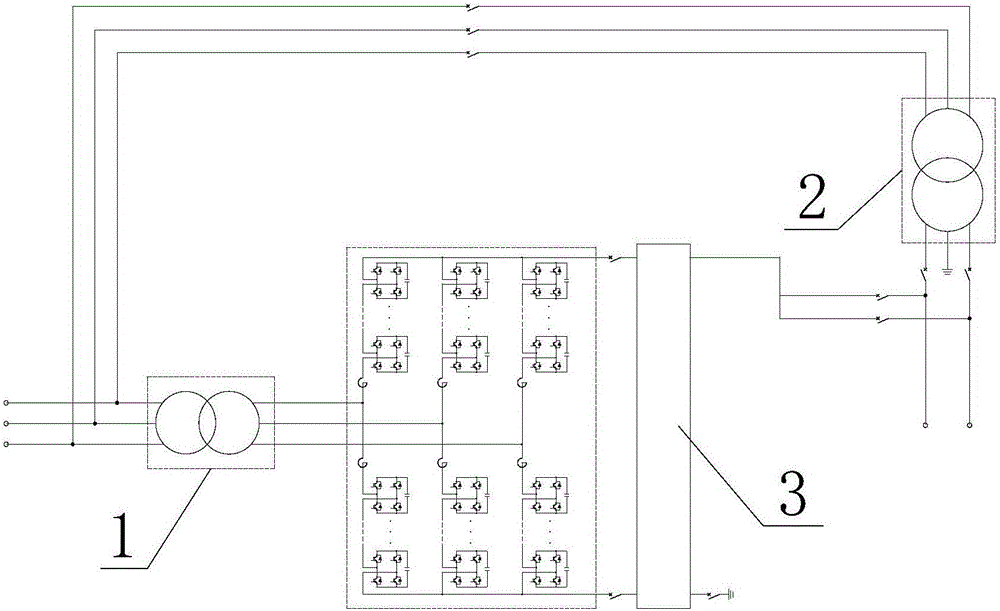

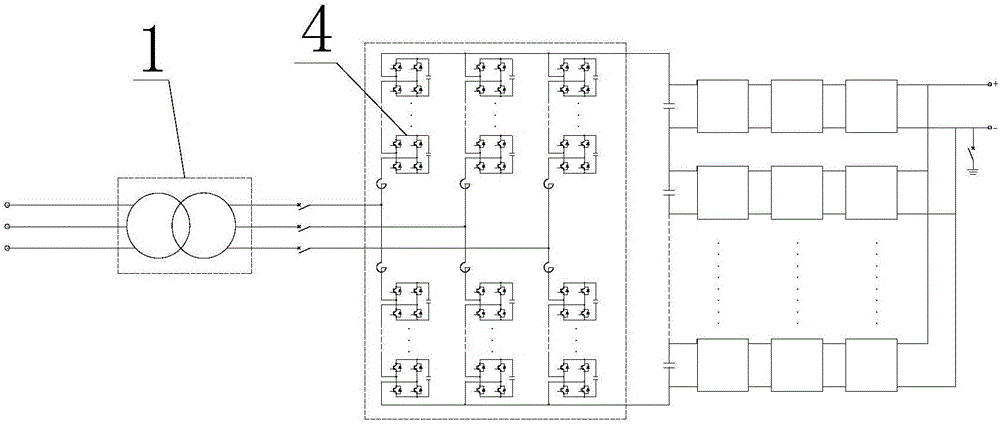

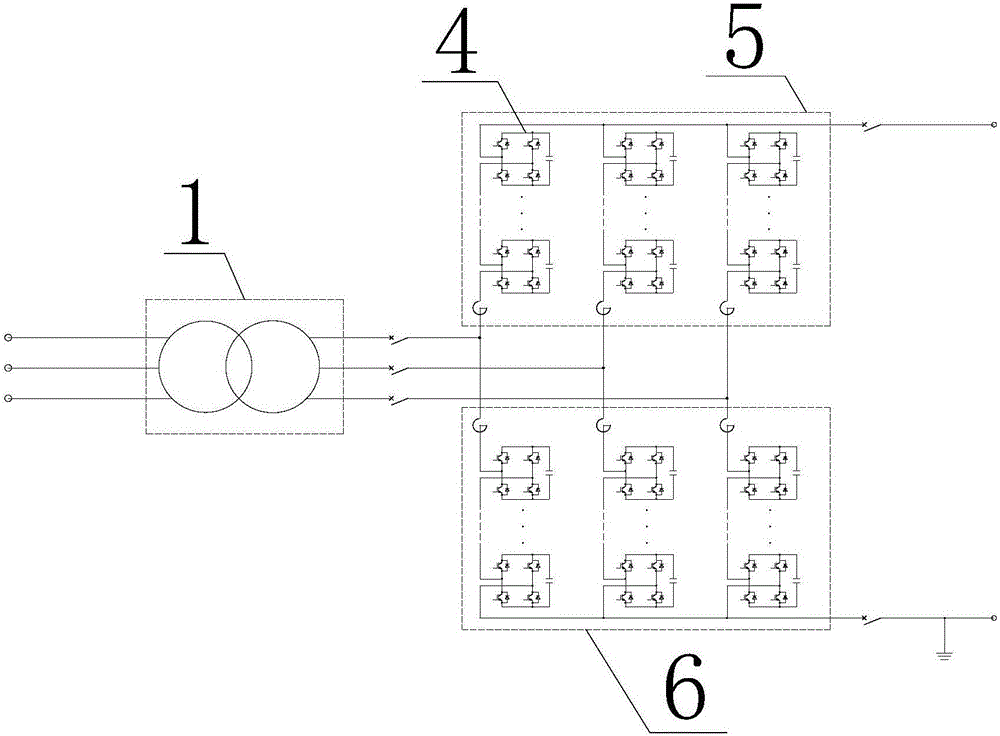

[0023] see image 3 , 4 , 5. The present invention provides a technical solution: a novel AC-DC hybrid traction power supply system, comprising a step-down transformer 1 and a converter, the converter is connected to the secondary side of the step-down transformer 1, and the converter Each bridge arm is composed of N H-bridge 4 circuits, the value range of N is N>1, and N is an integer, the H-bridge 4 includes S1, S2, S3 and S4, S1 and S4 are connected in series, S2 and S3 are connected in series, Then the two series structures are connected in parallel again. The control circuit of the inverter is composed of two SVG1 and SVG2 circuits with the same structure connected in parallel. SVG1 is composed of three H-bridges 4. One end of single-phase AC is connected, and the other end is connected to three-phase voltage sources A, B, and C respectively. The voltages at the two ends of the three bridge arms are Vau, Vbu, and Vcu respectively; the SVG2 unit is composed of three H-bri...

Embodiment 2

[0028] see Figure 4 , 5, 6. The other technical features of this embodiment are the same as those of Embodiment 1, the difference being that: the primary side of the step-down transformer 1 is connected to the output terminal through the traction transformer 2, and the secondary side of the step-down transformer 1 is connected to the output terminal. There are SVG1 and SVG2 circuits connected in series, and the input end of the converter is the output end of the traction substation. The power supply of the converter mainly completes the transformation from three-phase AC to DC, and requires fewer power units, thereby reducing the complexity of the control algorithm. In a sense, the stability of the system is improved, and the converter power supply in this embodiment can also be used for reactive power compensation when the DC power supply is not required.

Embodiment 3

[0030] see Figure 5 , 6 , 7. The other technical features of this embodiment are the same as those of Embodiment 1, the difference being that: Phase B on the secondary side of the step-down transformer 1 is grounded, Phase A and Phase C are connected to the output terminal through a series switch, and the step-down There are SVG1 and SVG2 circuits connected in series between the secondary side of transformer 1 and the output end. The input end in this embodiment is the output end of the traction transformer. The converter power supply in this embodiment mainly completes three-phase AC to DC or single-phase Phase-to-high-voltage AC conversion, when three-phase AC is converted into single-phase AC, it also meets the same-phase power supply requirements of main line electrified railways, and completely makes up for the shortcomings of the original single-phase unbalanced power supply. Of course, another working mode is the converter power supply. Only the three-phase AC to DC c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com