Acetylene gas purity detection device

A gas purity and detection device technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the scale of the absorption tube cannot be marked, the absorption tube cannot be detected, and the detection cost is high, so as to prevent detachment, avoid aging, enhance The effect of fixed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

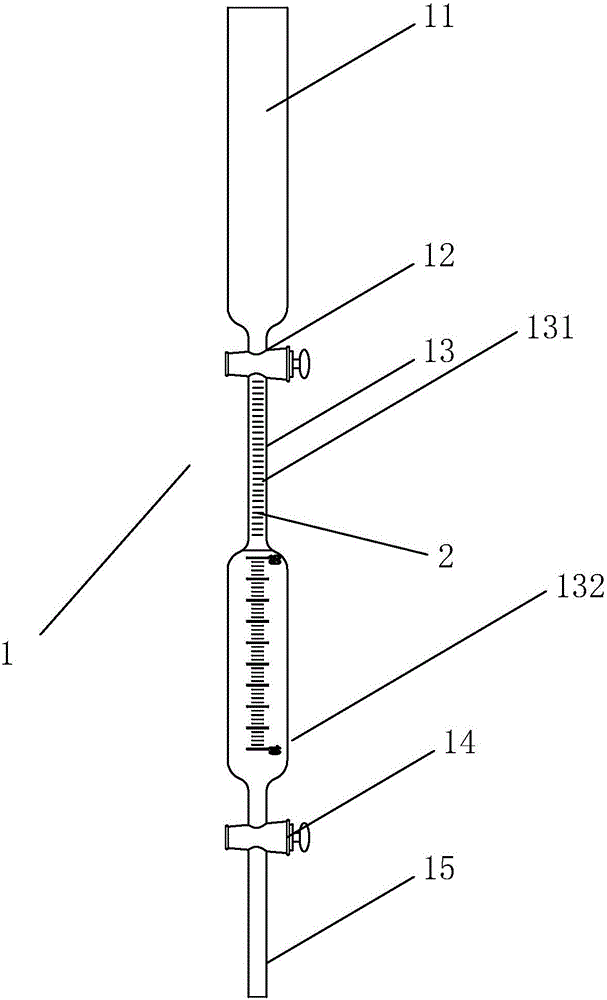

[0039] Embodiment 1: as figure 1 As shown, a device for detecting the purity of acetylene gas includes a tube body 1 made of glass, and the tube body 1 sequentially includes a cup-shaped reaction liquid container 11, a first cock 12, and a scale 2 from top to bottom. The absorption pipe 13, the second cock 14 and the intake pipe 15 below the second cock 14. During the detection process, by connecting the tank filled with high-pressure acetylene gas with the intake pipe 15, and then opening the second cock 14 and the first cock 12, the acetylene gas enters the absorption pipe 13 to replace the air in the absorption pipe 13, The air is completely removed from the pipe body 1, and then the second cock 14 is closed to stop the supply of high-pressure acetylene gas, then the first cock 12 is closed, and then the first cock 12 is turned so that the internal air pressure of the absorption pipe 13 is the same as the external air pressure, Then the potassium bromide saturated solution...

Embodiment 2

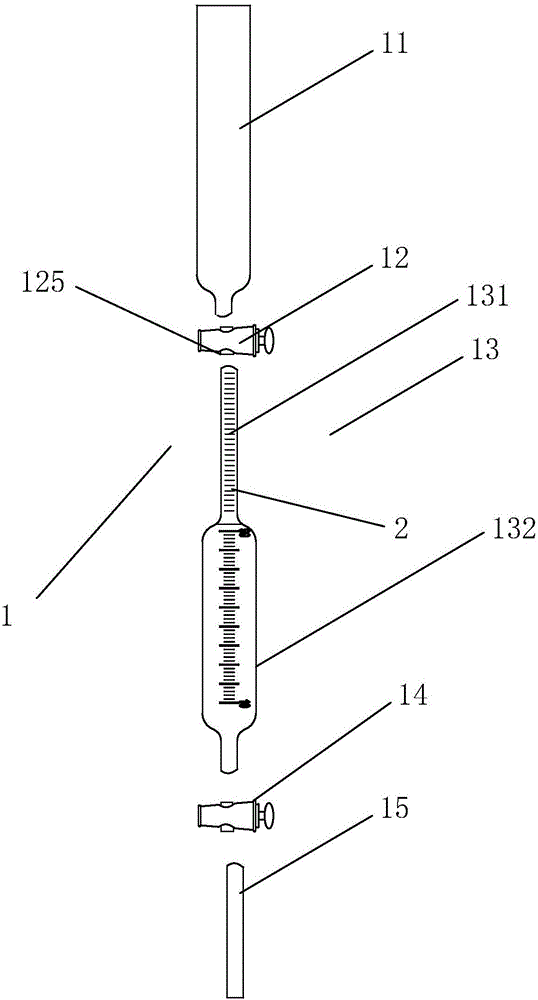

[0048] In embodiment 2, a kind of acetylene gas purity detection device, such as figure 2 As shown, the difference between embodiment 2 and embodiment 1 is that the connection methods of the two are different. In embodiment 1, the reaction solution containing part 11, the first cock 12, the absorption pipe 13, the second cock 14 and the inlet pipe 15 It is formed by integral molding. In embodiment 2, the components are detachably connected through cocks.

[0049] Such as figure 2 As shown, the reaction solution container 11 is detachably connected through the first cock 12 , the two ends of the absorption pipe 13 are detachably connected to the first cock 12 and the second cock 14 , and the air inlet pipe 15 is detachably connected to the second cock 14 .

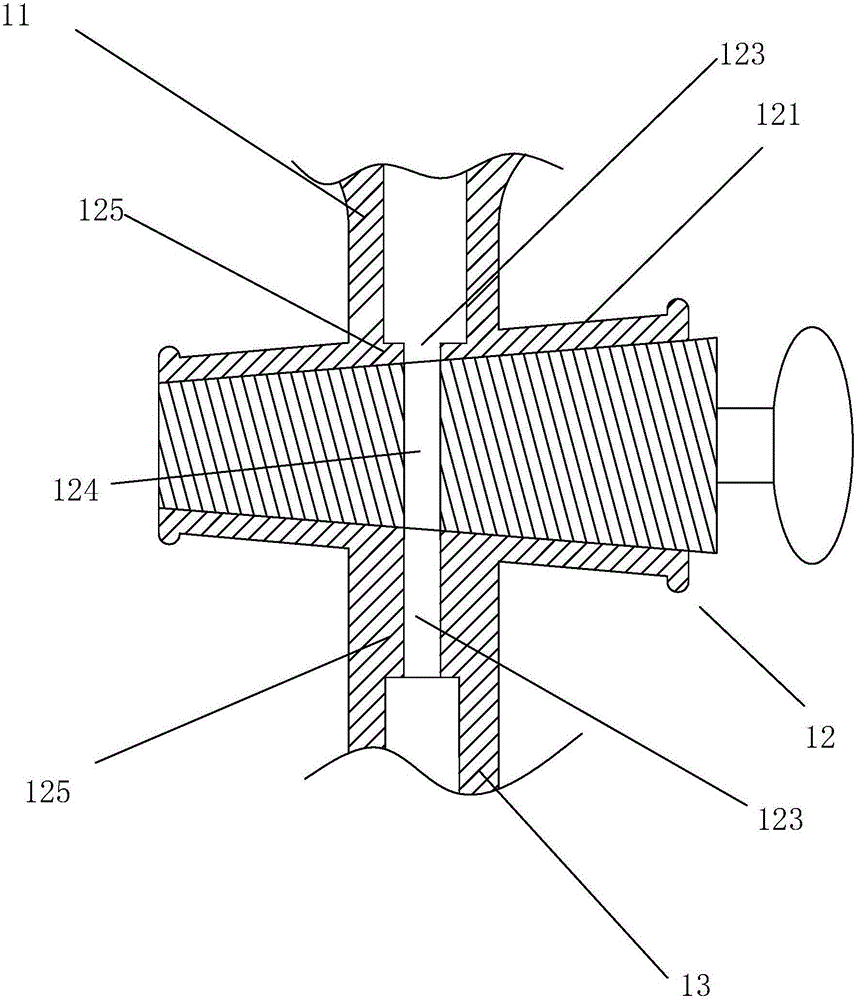

[0050] Such as Figure 4 and Figure 5 As shown, the detachable structure of the absorption pipe 13 and the first cock 12 is that the absorption pipe 13 and the first cock 12 are arranged separately, the upper end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com