Instrument pointer pulling force detection device

A technology of tension detection and instrument pointer, which is applied in the field of instrument detection, can solve the problems of low automation level, high operation difficulty affecting product qualification rate, low detection efficiency, etc., and achieve the effects of improving production efficiency, easy upgrading and transformation, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

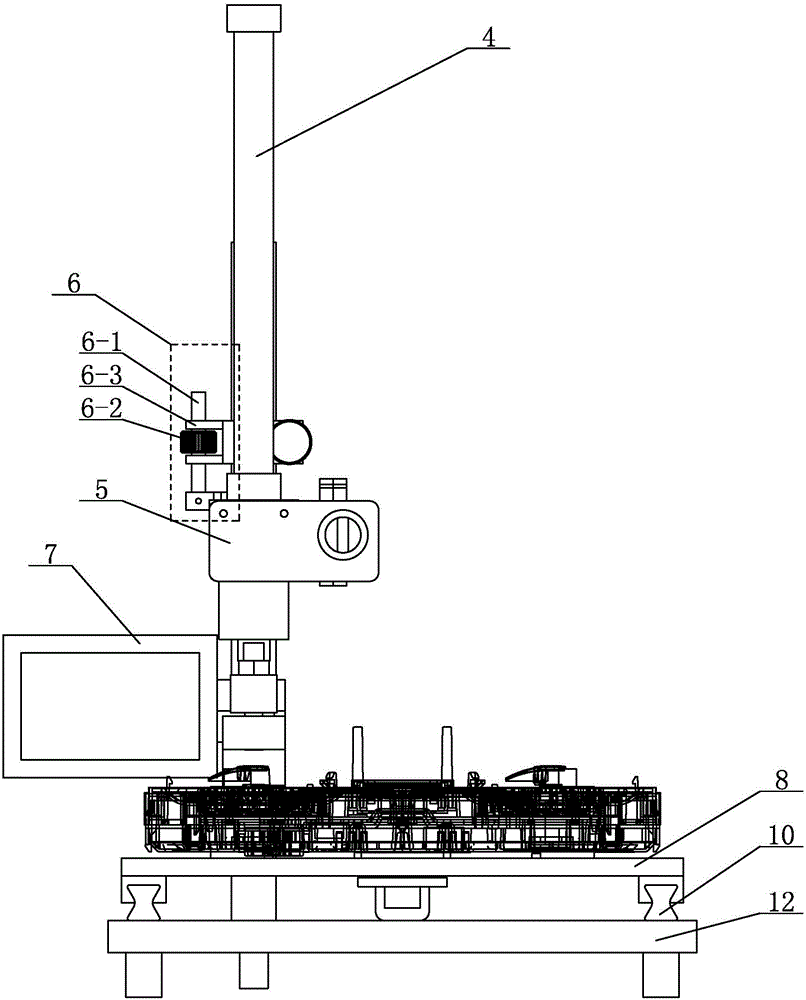

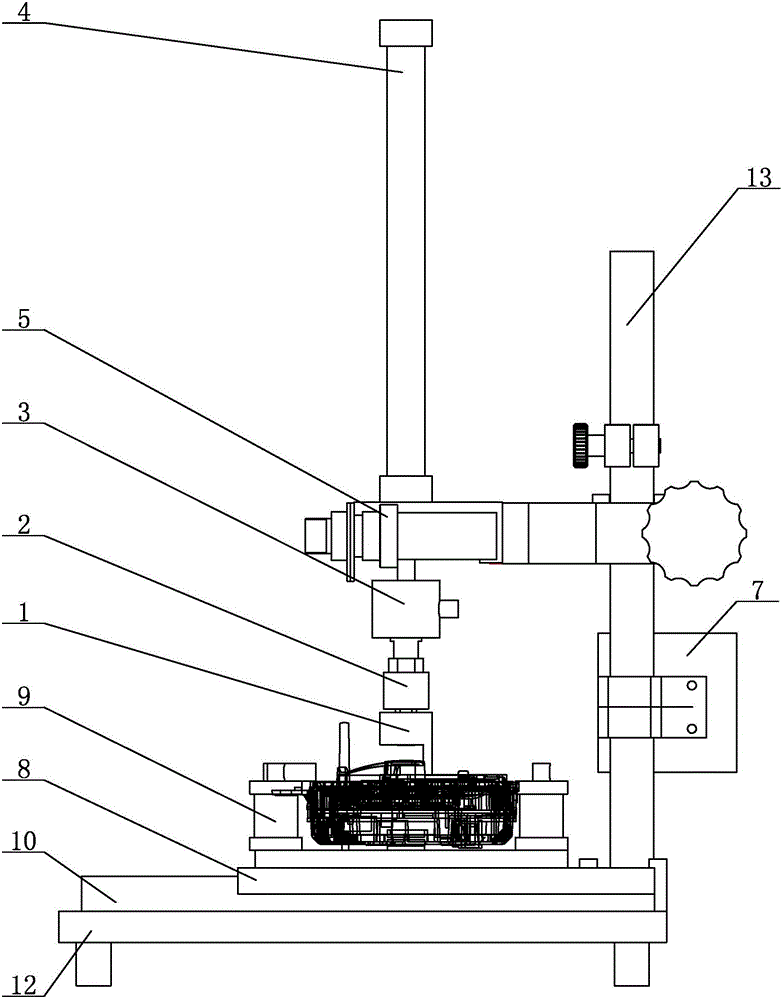

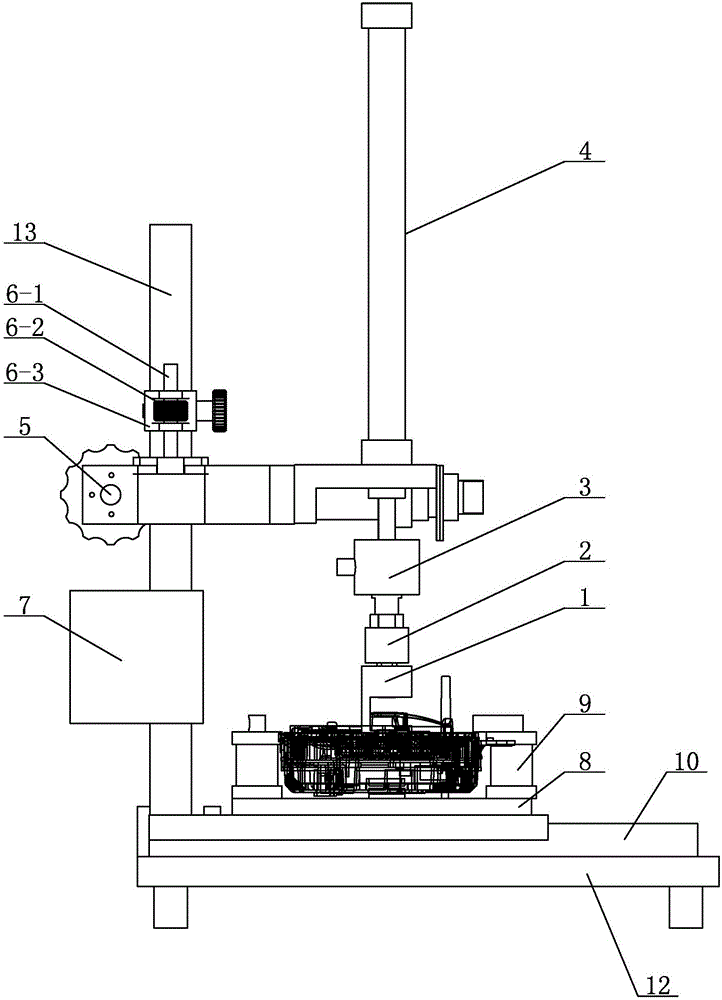

[0009] Specific implementation mode one: combine Figure 1 to Figure 4 Describe the present embodiment, the meter pointer tension detection device described in the present embodiment includes the pointer head 1, the center alignment mechanism 2, the tension sensor 3, the air cylinder 4, the lifting and clamping mechanism 5, the fixed instrument base 8, the rotating cylinder 9, Two slide rails 10, Y-axis push cylinder 11, base 12 and column 13, base 12 is set horizontally, two slide rails 10 are arranged side by side on the upper surface of base 12, fixed instrument base 8 is installed on two slide rails 10 , the Y-axis push cylinder 11 is installed on the upper surface of the base 12, the push rod of the Y-axis push cylinder 11 is connected with the fixed instrument base 8, the column 13 is vertically arranged on the upper surface of the base 12, and the cylinder 4 passes through the lifting and clamping mechanism 5 is connected with the column 13, the pointer head 1 is connec...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination Figure 1 to Figure 4 To illustrate this embodiment, an instrument pointer tension detection device described in this embodiment further includes a lifting fine-tuning mechanism 6, and the lifting fine-tuning mechanism 6 includes a fine-tuning screw 6-1, a fine-tuning nut 6-2, and a clamping part 6-3 of the fine-tuning mechanism. One end of the fine-tuning mechanism clamping part 6-3 is connected with the column 13, the fine-tuning screw rod 6-1 is connected with the other end of the fine-tuning mechanism clamping part 6-3, and the lower end of the fine-tuning screw rod 6-1 is connected with the elevating clamping mechanism 5, fine-tuning Nut 6-2 is sleeved on the fine-tuning screw rod 6-1. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination Figure 1 to Figure 4 To illustrate this embodiment, the instrument pointer tension detection device described in this embodiment further includes a tension digital display 7 , and the signal receiving end of the tension digital display 7 is connected to the signal transmitting end of the tension sensor 3 . Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com