Efficient shock absorption blasting and excavation method adopting fishbone-shaped construction guide grooves for large rock deep foundation pit in dense building area

A dense area, fishbone-shaped technology, used in construction, excavation, blasting, etc., can solve problems such as control technology reducing construction efficiency, and achieve the effect of reducing blasting vibration and dust pollution, reducing disturbance, and improving excavation construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

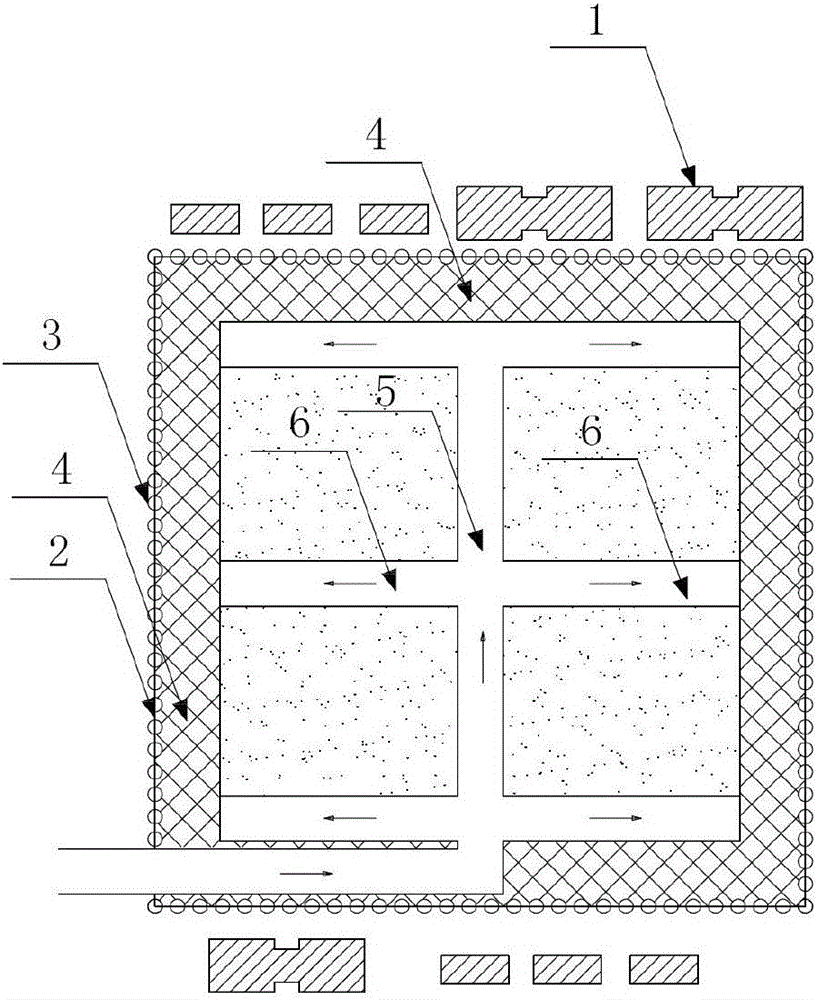

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0029] A large rocky deep foundation pit adjacent to a high-rise building 1 has a length, width and depth of 100m×100m×23m. The front and rear sides are densely built areas as shown in the figure. The following construction sequence is followed during excavation:

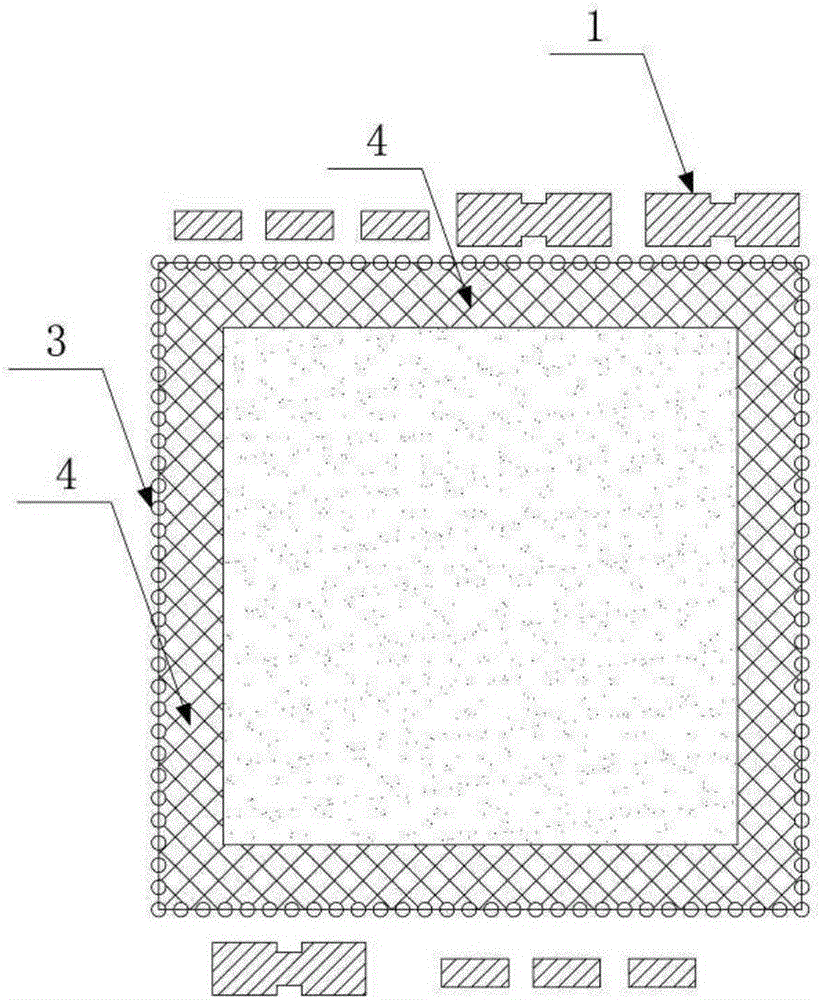

[0030] a. Drill vertical damping holes 3 whose depth exceeds the depth of the foundation pit along the contour line 2 of the outer edge of the foundation pit. The reserved protective belt 4 of box shape is not excavated temporarily in the square area surrounded by, and the thickness of reserved protective belt 4 is determined according to actual needs, and the present embodiment is preferably 10m (see figure 1 ).

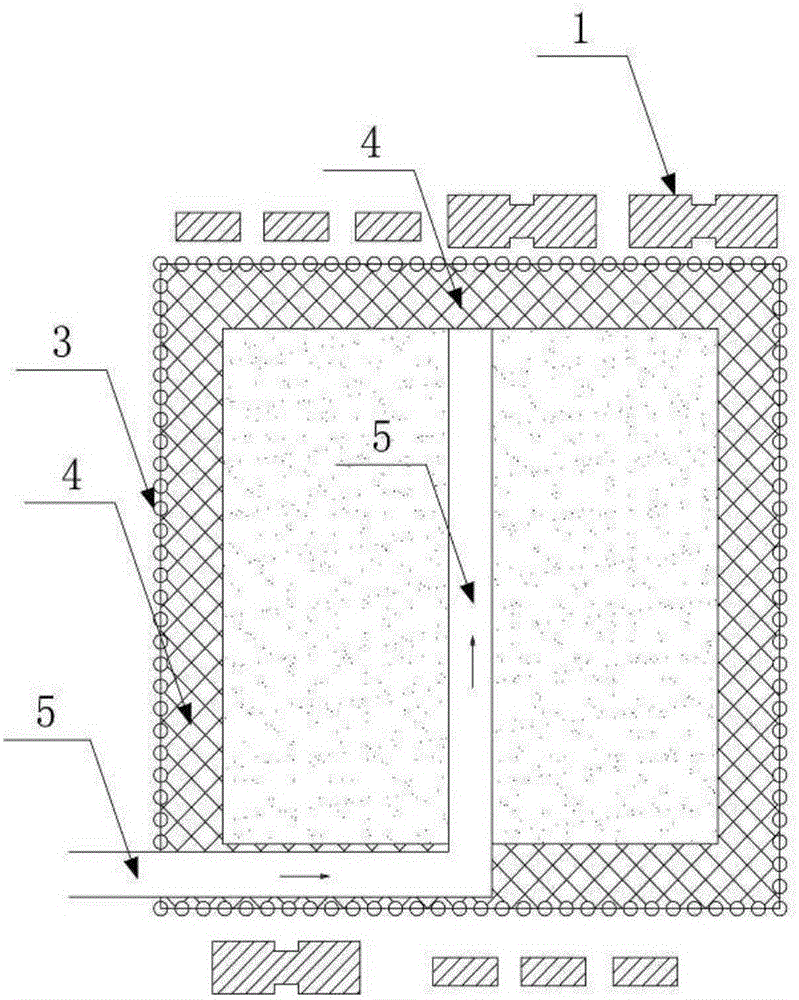

[0031] b. Towards the dense direction of high-rise buildings 1, a main construction guide groove 5 is excavated by shallow hole loosening blasting method (see figure 2 ). The section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com