Lamp part connecting structure

A technology for connecting structures and components, which is applied in the field of connecting structures for lamp components, and can solve problems such as breakage of protrusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

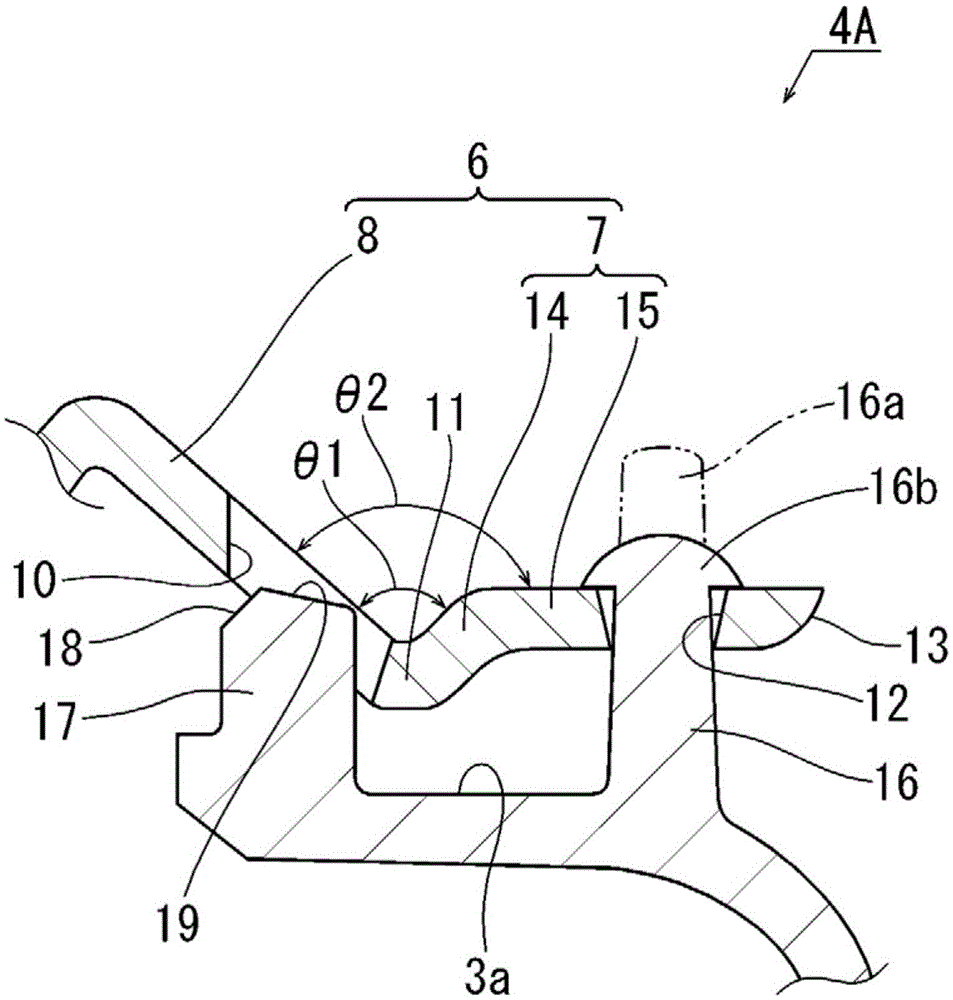

[0040] Embodiments of the present invention will be described below with reference to the drawings. In the following embodiments, various limitations are made on constituent elements, types, combinations, shapes, relative arrangements, etc., but these are merely examples, and the present invention is not limited thereto.

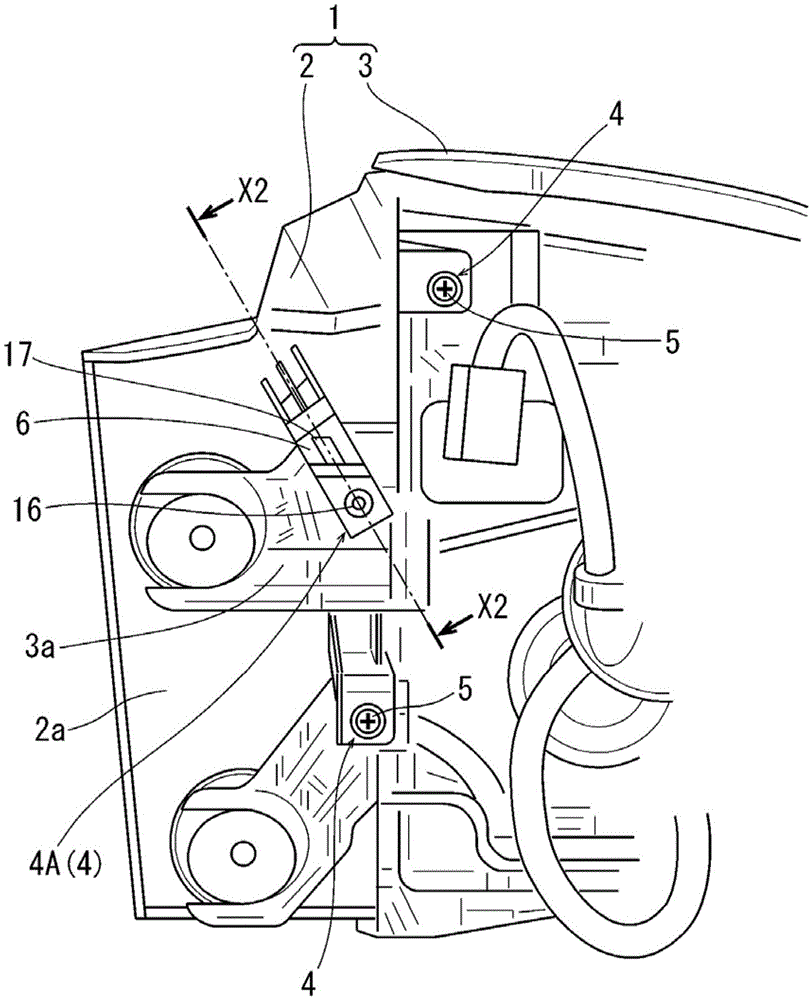

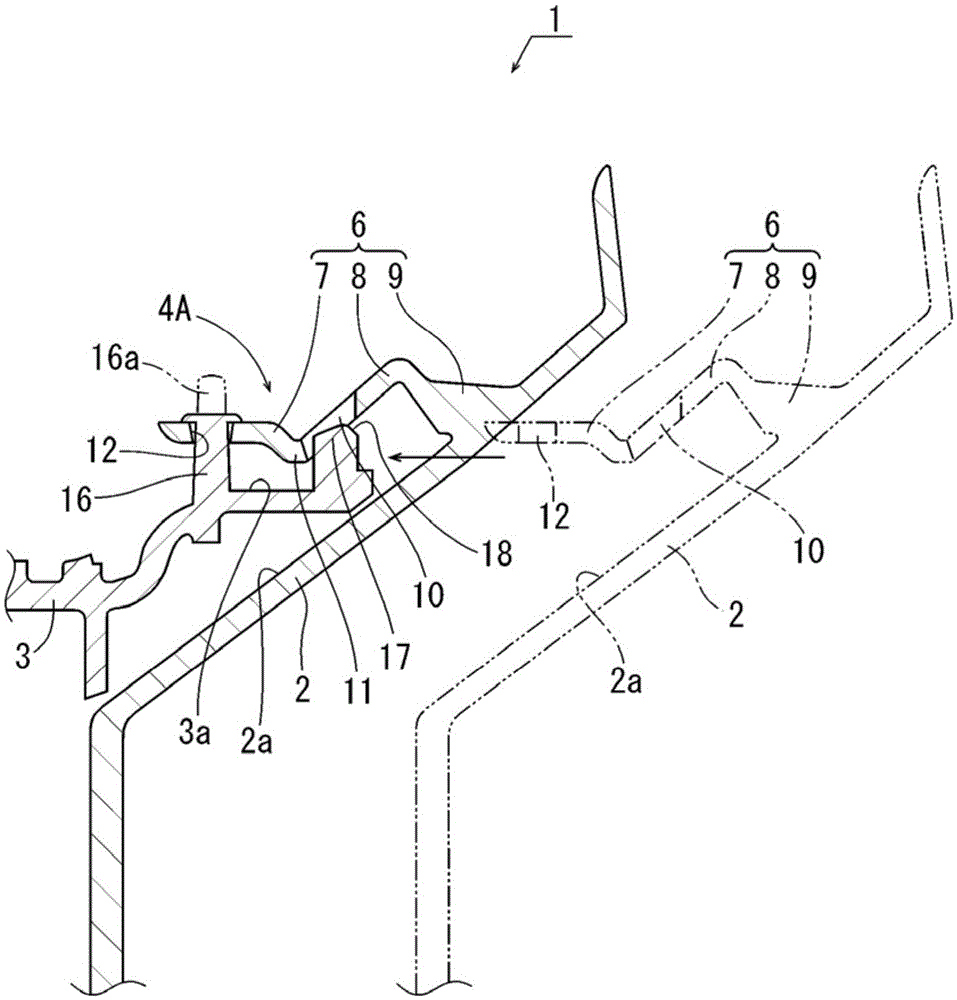

[0041] exist figure 1 Among them, symbol 1 is a vehicle lamp. A vehicle lamp 1 includes a resin-made bezel 2 as a first component, and a resin-made lamp body 3 as a second component. The connecting part 4 connects the light shielding plate 2 and integrates it.

[0042] At two of the plurality of connecting parts 4, the visor 2 and the lamp body 3 are connected by using the stopper 5, and on the other hand, at the connecting part 4A, which is one of the plurality of connecting parts 4, the light shielding plate 2 and the lamp body 3 are connected by using heat The shading plate 2 and the lamp body 3 are connected by riveting.

[0043] In the above connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com