Compressor set capable of achieving gas-liquid mixed delivery function

A compressor unit and gas-liquid mixed transmission technology, which is applied in the field of compressor units, can solve problems such as high transportation costs and environmental pollution, and achieve reliable performance, avoid poor drainage, and excellent economic problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

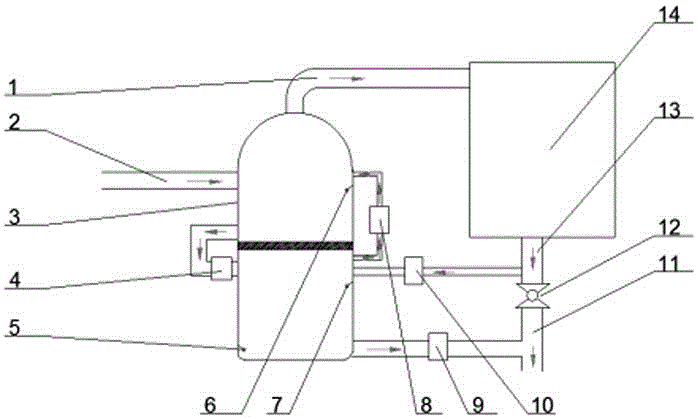

[0031] Such as figure 1 As shown, a compressor unit that can realize the function of gas-liquid mixed transportation includes a separator 3 and a compressor 14. The separator 3 is provided with a layered partition, and the layered partition stores the separator 3. The space is divided into an upper chamber and a lower chamber, and the upper chamber is connected with an air inlet pipe 2 and an air outlet pipe 1, and the connection point between the air outlet pipe 1 and the upper chamber is located above the upper chamber, and the air outlet pipe The other end of 1 links to each other with the air inlet of compressor 14;

[0032] It also includes an oil filter pipe whose two ends are respectively connected to the lower end of the upper chamber and the lower chamber, and the oil filter pipe is provided with a one-way valve 4 with a downward flow direction;

[0033] It also includes a gas return pipe with two ends connected to the upper end of the lower chamber and the upper cha...

Embodiment 2

[0042] Such as figure 1 As shown, the present embodiment is further limited on the basis of Embodiment 1: as a method to automatically change the first shut-off valve 8, the third shut-off valve 10 and the second shut-off valve according to the liquid level of the liquid component in the lower chamber 9 The technical scheme of the on-off state of the three, also includes a float switch arranged in the lower chamber, the first shut-off valve 8 is a normally open valve, and the third shut-off valve 10 and the second shut-off valve 9 are Normally closed valve, when the float switch is triggered because the liquid level in the lower chamber rises, the on-off state of the first shut-off valve 8, the third shut-off valve 10 and the second shut-off valve 9 changes; the said When the float switch returned to the natural state because the liquid level in the lower chamber was lower, the on-off states of the first shut-off valve 8, the third shut-off valve 10 and the second shut-off val...

Embodiment 3

[0050] This embodiment is further limited to this case on the basis of embodiment 1, as figure 1 As shown, in order to avoid failure of the compressor 14 caused by the high liquid level in the upper chamber due to poor drainage of the upper chamber of the separator 3 or excessive liquid components entering the upper chamber from the intake pipe 2 in a short period of time, the Also be provided with the second float switch 6 in above-mentioned chamber, described second float switch 6 is connected with the control module of compressor 14, in described second float switch 6 because the liquid level rises in the chamber, When high is triggered, the compressor 14 shuts down. The above second float switch 6 can protect the compressor 14 by converting the liquid level signal into an electrical signal and acting on the control module of the compressor 14 . Preferably, the above second float switch 6 is a float valve. By setting the outlet end of the float valve far away from the 14 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com