Composite column and foundation joint structure with horizontal seismic performance and its construction method

A technology of horizontal earthquake resistance and node structure, applied in earthquake resistance, building components, building structure, etc., can solve the problems of consumption of concrete and steel bars, cracking of concrete protective layer, easy damage of concrete, etc., to achieve tensile and compressive strength. Improved, high strength, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

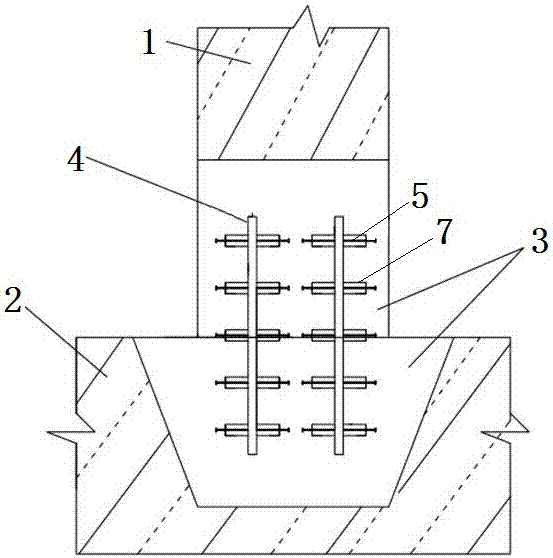

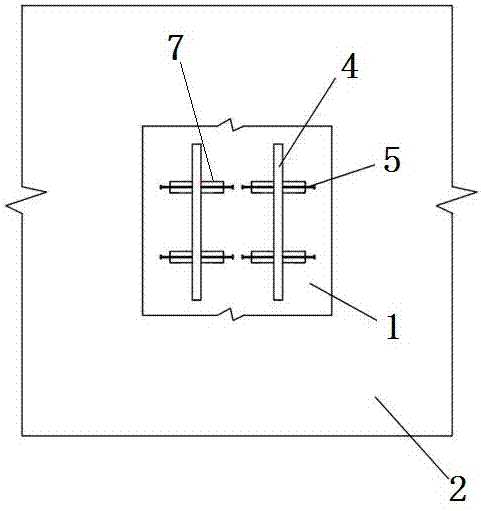

[0023] Such as Figure 1-4 As shown, a composite column and foundation node structure with horizontal seismic performance includes a composite column 1 and a foundation 2, and the poured concrete layer 3 at the connection node of the composite column and the foundation is connected as a whole, and the inside of the concrete layer At least two vertical steel plates 4 are buried horizontally, and several stud bolts 5 are arranged in a matrix on the surface of each vertical steel plate, and the stud bolts pass through the vertical steel plate surface vertically and are welded on the vertical steel plate, The head bolt and the vertical steel plate form a rigid body, and the two ends of the stud bolt are welded with nuts 6, which can improve the rigidity of the whole stud bolt. The casing 7 is made to be integrated with the peripheral part of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com