Automatic sea floating garbage collecting barrel

A garbage collection and marine technology, applied in the field of trash cans, can solve problems such as inability to achieve good results, inability to effectively protect the cleanliness of oceans and rivers, time-consuming and labor-intensive, saving manpower and resources, and preventing seawater pollution in advance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

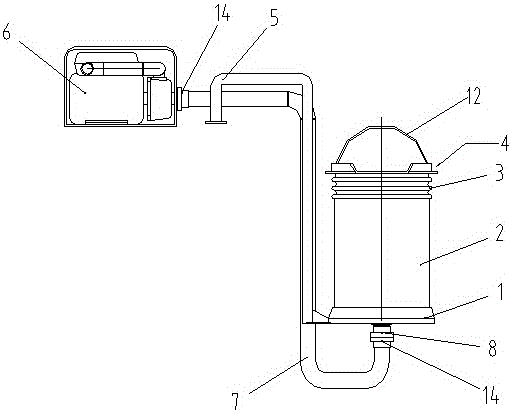

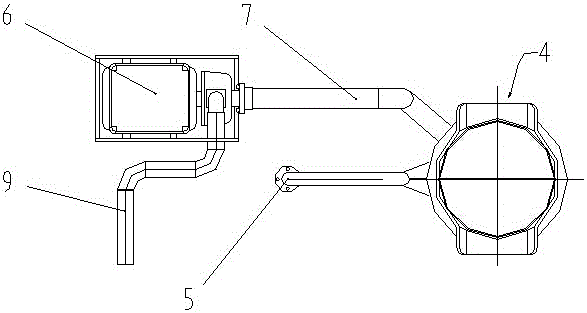

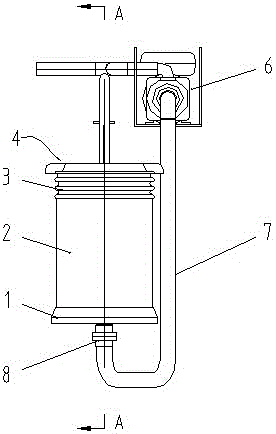

[0036] Examples such as Figure 1-5 As shown, the automatic marine floating garbage collection bucket includes a metal outer barrel body 2, an upper opening of the outer barrel body 2, a metal base 1 is fixedly installed on the bottom of the outer barrel body 2, and a metal base 1 is fixedly installed at the opening of the outer barrel body 2. There is a collection port 4, a telescopic rubber cover 3 is arranged between the outer barrel body 2 and the collection port 4, one end of the telescopic rubber cover 3 is connected to the outer barrel body 2, and the other end of the telescopic rubber cover 3 is connected to the collection port 4 .

[0037] The collection port 4 includes a cylindrical housing 401, the upper and lower ends of the housing 401 are open, the lower opening of the housing 401 is connected with the telescopic rubber cover 3, and the side wall of the housing 401 is provided near the upper opening. There is a garbage hopper 402, and the garbage hopper 402 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com