Electrochemical reforming system for dry reforming of methane and carbon dioxide and construction method and using method of electrochemical reforming system for dry reforming of methane and carbon dioxide

A carbon dioxide and reforming system technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of catalyst deactivation, high temperature conditions, etc., and achieve the effect of high selectivity, high conversion rate, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

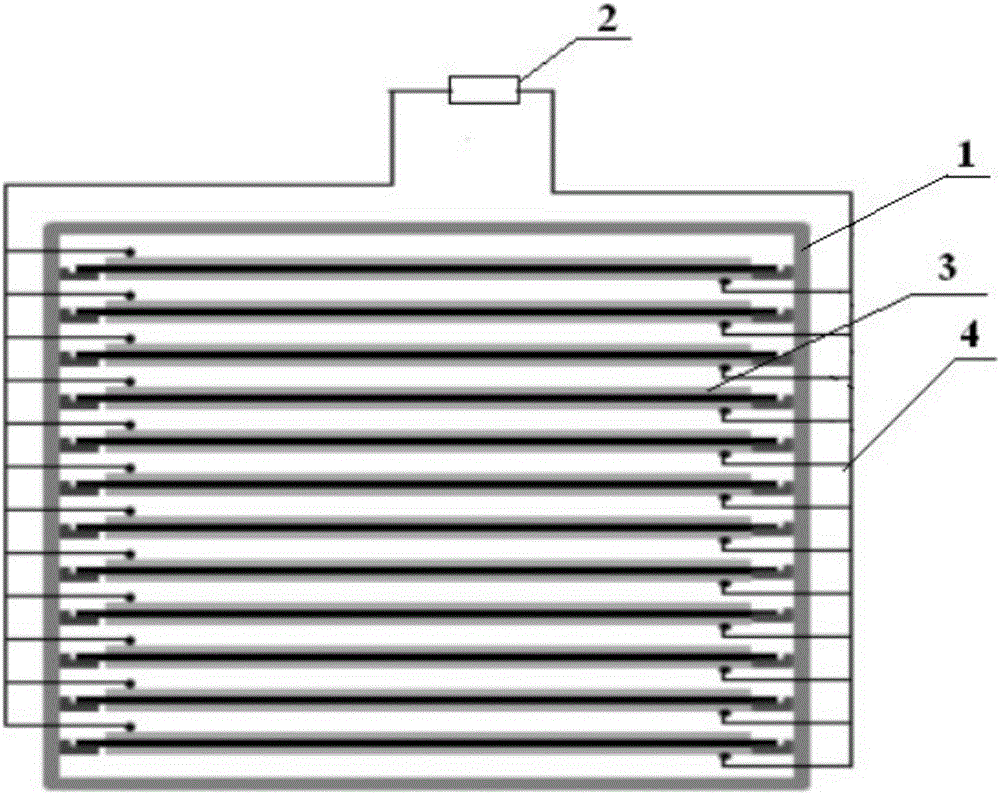

[0015] Specific Embodiment 1: In this embodiment, an electrochemical reforming system for dry reforming of methane and carbon dioxide includes a plurality of electrolytic cell sheets, a reactor 1 and an external power supply 2; the plurality of electrolytic cell sheets are arranged in parallel in the horizontal direction In the reactor 1, the electrolytic cell sheet includes an electrolyte film 3 and two porous electrodes 4, the upper surface and the lower surface of the electrolyte film 3 are respectively connected to the two porous electrodes 4, and the porous electrodes 4 are connected to the external power supply 2 through wires. connected.

[0016] The external power supply in this embodiment is direct current or alternating current.

[0017] The electrolytic cell of the system in this embodiment is composed of electrolytes and electrodes. If the power supply is direct current, dissociation of carbon dioxide occurs in the cathode to generate carbon monoxide and oxygen ion...

specific Embodiment approach 2

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the reactor described in 2 is a ceramic tube or a glass tube. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific Embodiment Three: In this embodiment, a construction method of an electrochemical reforming system for dry reforming of methane and carbon dioxide is as follows: 1. The electrolyte material is prepared into an electrolyte film by a casting method, and then sintered at a high temperature to obtain a dense electrolyte film 3; 2. Prepare electrodes on both sides of the dense electrolyte film 3 by screen printing, and then use a pore-forming agent and high-temperature calcination to obtain a porous electrode 4; 3. Prepare a confluence layer on the porous electrode 4 by screen printing, and then After high-temperature sintering, electrolytic cell sheets are obtained; 4. Place n electrolytic cell sheets in reactor 1, and then communicate with external power supply 2 through porous electrodes 4 and wires to obtain an electrochemical reforming system for dry reforming of methane and carbon dioxide, wherein n≥1.

[0020] The electrochemical reforming method proposed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com