Product detecting and sorting system

A sorting system and product technology, applied in the direction of sorting, conveyors, conveyor objects, etc., can solve the problems of limited product quantity and limited product delivery, so as to improve accuracy, improve production efficiency, and improve the overall quality level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

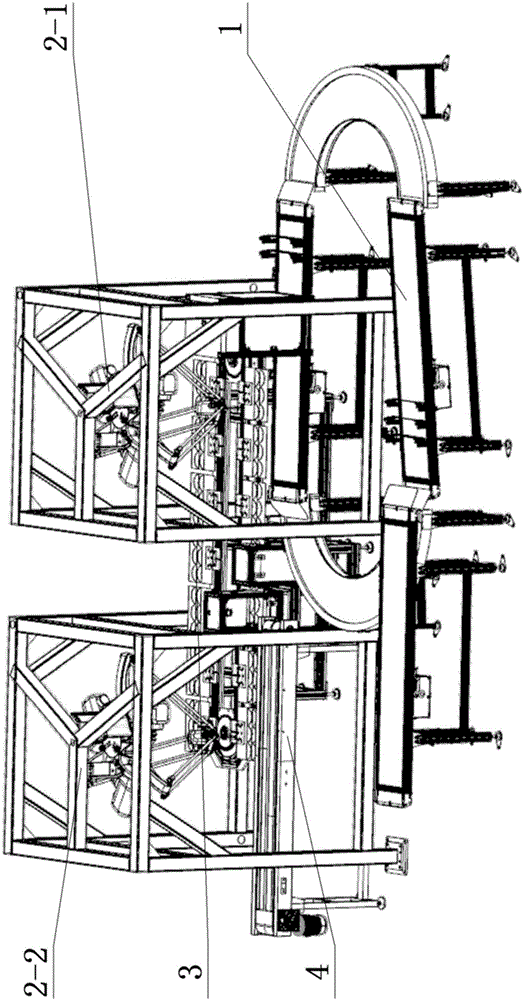

[0031] A product detection and sorting system includes an annular feeding line 1, a first grabbing manipulator 2-1, a second grabbing manipulator 2-2, an annular detection line 3 and a finished product conveyor belt 4; a first grabbing manipulator 2-1 The structure is exactly the same as that of the second grabbing manipulator 2-2. The annular detection line 3 is arranged on one side of the annular feeding line 1, and the first grabbing manipulator 2-1 is disposed between the annular feeding line 1 and the annular inspection line 3. Above, it is used to grab the products on the ring feeding line 1 to the ring detection line 3, the finished product conveyor belt 4 is arranged on one side of the ring detection line 3, and the second grasping robot 2-2 is arranged on the ring detection line 3 and the ring detection line 3. The upper part of the finished product conveyor belt 4 is used for grabbing the products on the annular detection line 3 onto the finished product conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com