An intelligent bottle sorting and recycling machine

A technology for recycling machines and bottles, which is applied in glass recycling, recycling technology, garbage collection, etc., can solve the problems of complex overall structure, small scope of application, and large occupied space, and achieve compact overall structure, low manufacturing cost, and low occupation small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

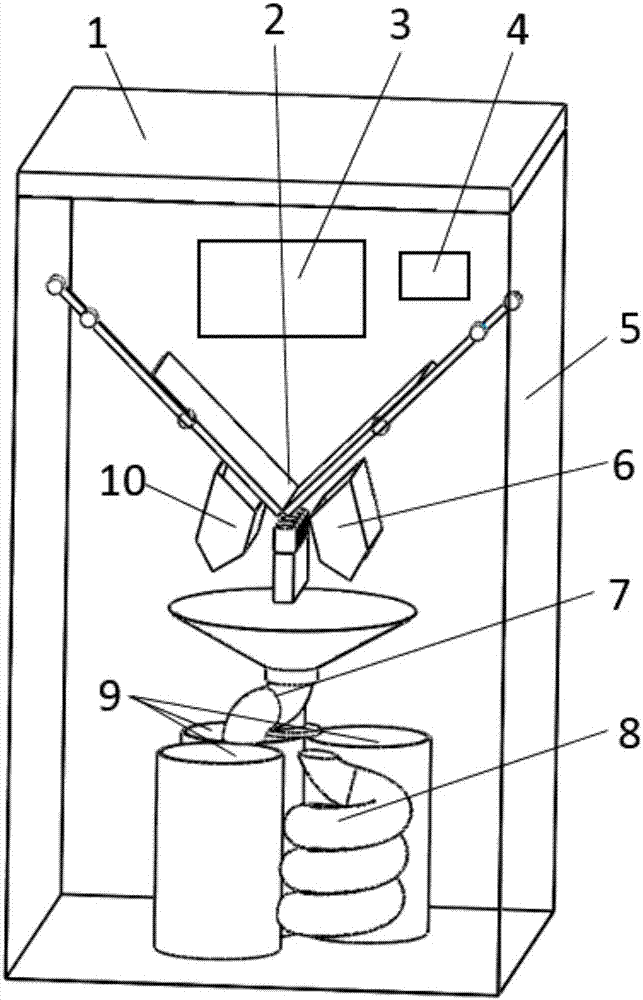

[0052] Such as figure 1 As shown, the intelligent bottle sorting recycling machine of the present embodiment includes:

[0053] The energy supply module has a solar panel 1 and a storage battery (not shown in the figure), and is used to supply power to the entire recycling machine.

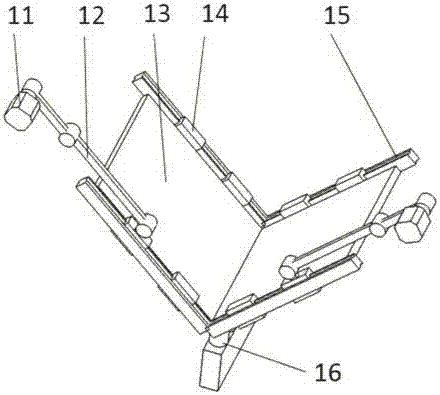

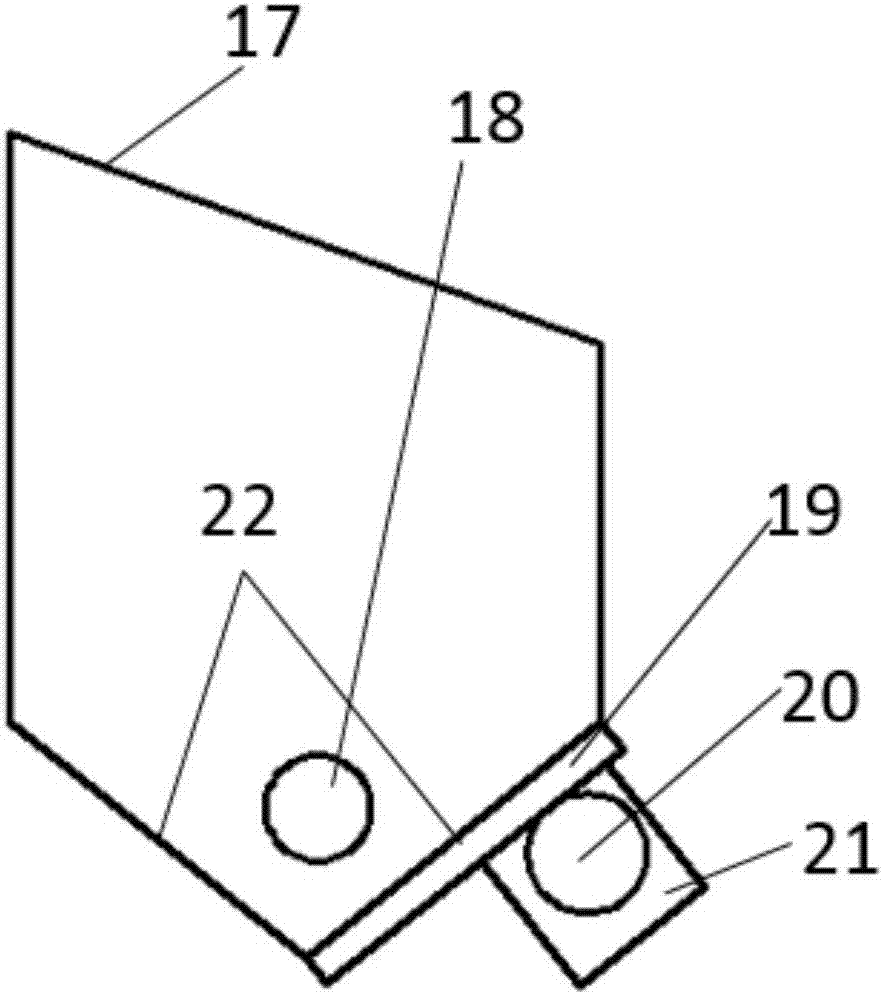

[0054] Metal detection chamber 2, such as figure 2 As shown, two obliquely arranged movable baffles 13 form a cavity structure with a wide top and a narrow bottom. The bottle at the bottom of the metal detection chamber 2, the crank slider mechanism 12 is used to drive the movement of the movable baffle 13 to open the metal detection chamber 2, the crank slider mechanism 12 is driven by the servo motor 11, and the metal detection chamber 2 can be used for bottles. The first-level inspection is initially divided into metal bottles and non-metal bottles.

[0055] When the bottle is dropped into the metal detection chamber 2 and falls, the metal sensor 16 starts to detect, and when detecting meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com