First process fixture for processing engine water pipe and first process processing method adopting first process fixture

An engine and water pipe technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of fine turning affecting the blank, difficult clamping of irregular workpieces, affecting the production efficiency of water pipes, etc. High reliability, convenient clamping operation and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

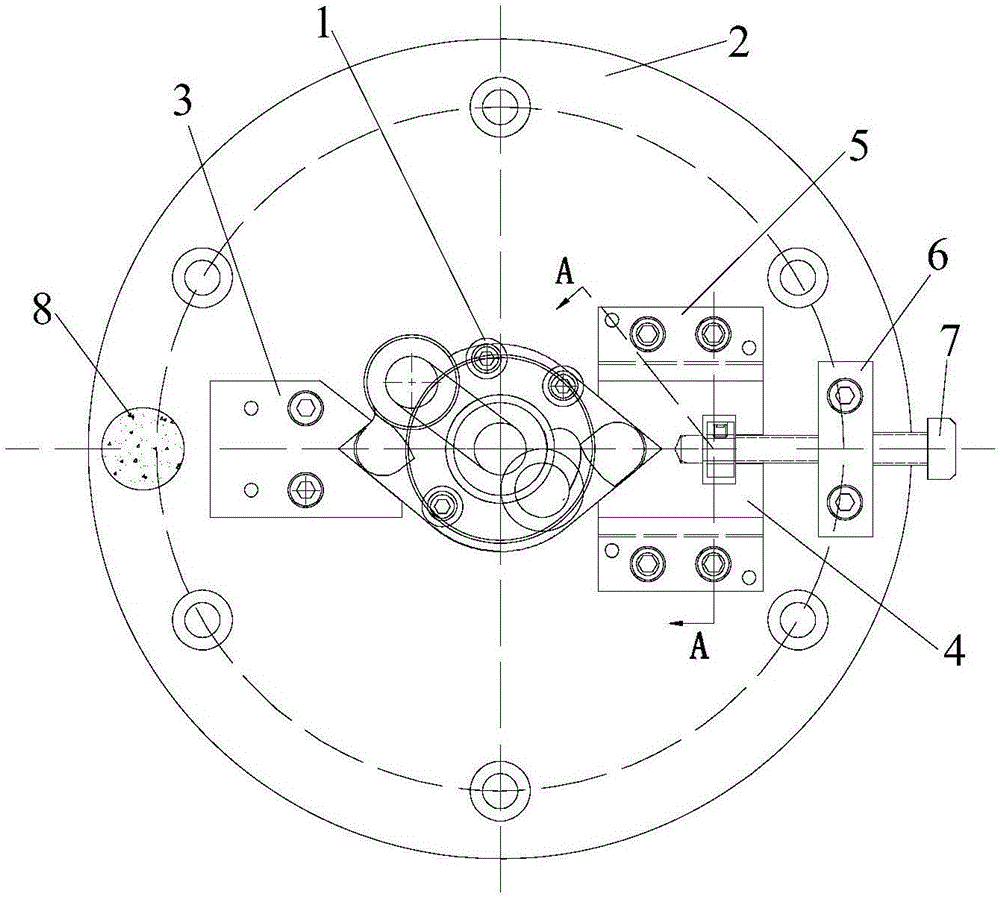

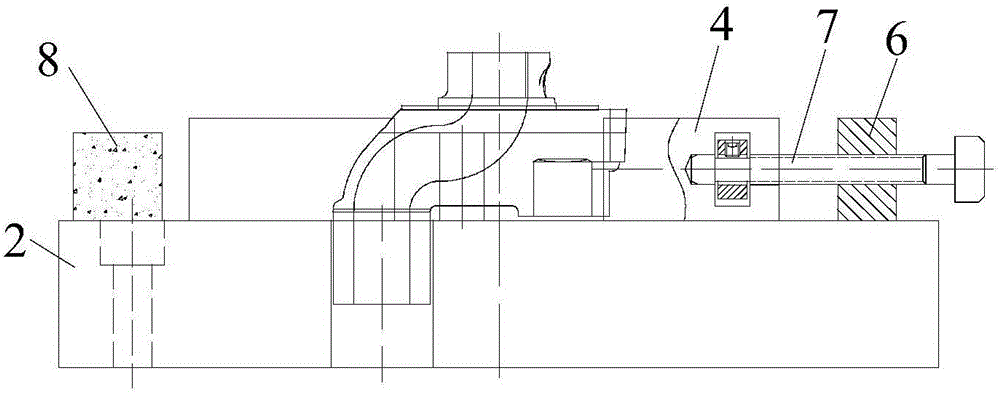

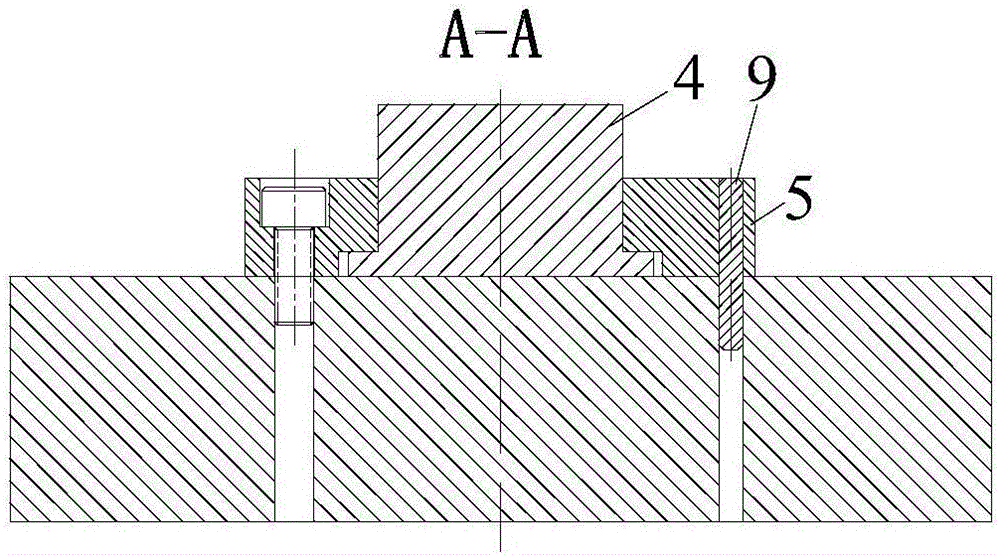

[0029] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

[0030] Such as Figure 1 to Figure 3 As shown, the present invention provides a first-order fixture for engine water pipe processing. The engine water pipe is made of a water pipe blank through the first-order finishing machining, the second-order finishing machining and the third-order finishing machining. The fixture is used to clamp the water pipe blank when the water pipe blank is processed in the first sequence of finishing turning. The structure of the water pipe blank is as follows Figure 9 to Figure 11 As shown, it includes a flange 10 and a first pipe body 11, a second pipe body 12, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com