Paint spraying device for pipeline

A technology of pipelines and locking devices, applied in the direction of spraying devices, etc., can solve problems such as repeated clamping and paint spillage, and achieve the effects of reducing physical health, low production costs, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

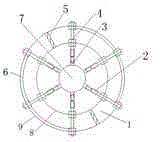

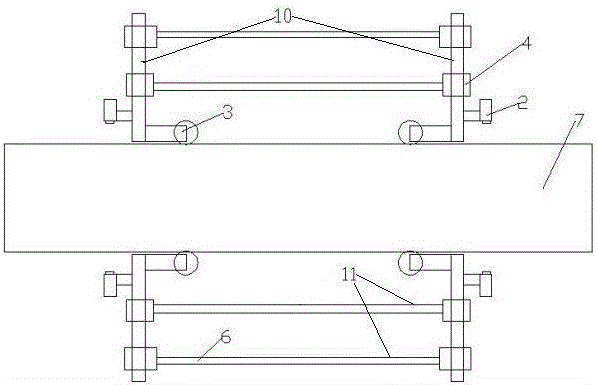

[0008] Depend on figure 1 Provided, a pipe painting device of the present invention includes a frame 1, and the frame 1 includes two sets of support frames 10 parallel to the front and back, and the support frames 10 include an inner circle support 8 and an outer circle support 9, and the two sets of supports The frames 10 are connected by connecting rods 11. The support frame 10 is equipped with six spray heads 2, six wheels 3 and six sets of adjustment mechanisms 4. The support frame 10 is fixed with the pipeline 7 through the locking device 5. The outer circular support 9 is provided with a delivery pipe 6, and the locking device 5 is a buckle structure.

[0009] figure 2 It is an axial schematic diagram of a pipeline paint spraying device of the present invention. The pipeline paint spraying device adopts an automatic control method, and travels along the pipeline 7 with the help of the wheel 3 driven by a stepping motor at the bottom. The nozzle 2 sprays the paint even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com