A dense-phase semi-dry desulfurization device and its operating method

A technology of semi-dry desulfurization and operation method, which is applied in the field of sintering machine dense-phase semi-dry desulfurization device and sintering machine desulfurization device. and other issues, to achieve the effect of saving investment, significant economic and social benefits, and great promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

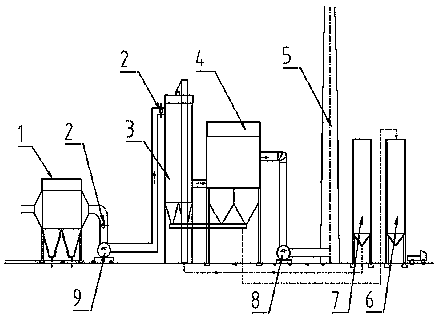

Image

Examples

Embodiment 1

[0031] Preparatory work: 1 DN900mm switch-type mixing air valve is installed in each of the 9 inlet main flue ducts (dual channels) of the main exhaust fan of the sintering machine, equipped with a silencer, and the temperature drop can reach up to 50°C;

[0032] The inlet flue of the dense-phase semi-dry desulfurization device is equipped with two DN900mm switch-type air mixing valves, equipped with a silencer, and the temperature drop is ≥ 50°C;

[0033] The original bypass valve of the sintering machine is blocked, and all interlocking, control, alarm and other related procedures are cancelled;

[0034] The computer screens of the sintering central control room and the desulfurization central control room display their respective fan pressure, damper opening, fan start signal and other parameters.

[0035] A. Start-up operation specific operation steps:

[0036] (1) 10 minutes before starting the main exhaust fan 9 of the sintering machine, start the desulfurization booste...

Embodiment 2

[0051] Preparatory work: The main exhaust fan 9 of the sintering machine is installed in the main flue (single flue) with a DN900mm switch-type air mixing valve 2, equipped with a silencer, and the temperature drop can reach up to 50°C;

[0052] The inlet flue of the dense-phase semi-dry desulfurization device is equipped with two DN900mm switch-type air mixing valves 2, equipped with a silencer, and the temperature drop is ≥ 50°C;

[0053] The original bypass valve of the sintering machine is blocked, and all interlocking, control, alarm and other related procedures are cancelled;

[0054] The computer screens of the sintering central control room and the desulfurization central control room display their respective fan pressure, damper opening, fan start signal and other parameters;

[0055] A. Start-up operation specific steps:

[0056] (1) 8 minutes before starting the main exhaust fan 9 of the sintering machine, start the desulfurization booster fan 8, open the air mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com