An impurity separation device for petroleum storage tanks

A separation device and oil storage tank technology, which is applied in the field of oil storage tanks, can solve the problems of difficult cleaning of oil storage tank deposits, and achieve the effects of avoiding use costs, reducing floor space, and rapid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

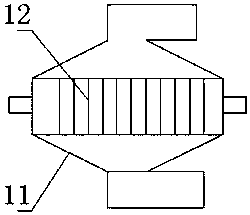

[0028] Such as figure 1 Shown, the impurity separating device that is used for petroleum storage tank of the present invention comprises the spindle-shaped separator that vertically arranges; The separator is divided into heavy region, medium region, and light region from bottom to top; A heavy outlet is set in the quality area, a light outlet is set in the light area, a separation outlet and a separation inlet are respectively set on opposite sides of the middle area, and a buffer device is provided in the middle area, and the buffer device includes a buffer frame and A plurality of flexible buffer bars; the buffer bars are vertically arranged in the separator and fixed by the buffer frame.

[0029] The heavy area is funnel-shaped, the light area is cone-shaped, and the height ratio of the heavy area, the medium area, and the light area is (2-4): (6-8): (1-3); On average, there are 80-110 buffer strips per cubic meter in the medium quality area. This structure can facilitat...

Embodiment 2

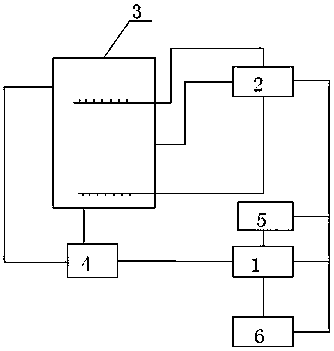

[0035] Such as figure 2 As shown, the filter system based on the separation device of embodiment 1 includes an oil tank body 3, a mixer 4, a first filter 5, and a second filter 6; the separation device includes a first separator 1 and a second separator 2; The mixer 4 is connected to the upper part and the bottom of the oil tank body 3 through pipelines and respectively extracts the oil from the upper part and the lower part of the oil tank body 3 for mixing, and the output end of the mixer 4 is connected to the first separator 1, the second The separation outlet of a separator 1 communicates with the separation inlet of the second separator 2, the heavy outlet communicates with the separation inlet of the second separator 2 through the second filter 6, and the light outlet communicates with the second separator 2 through the first filter 5. The separation inlet of the separator 2 is connected; the separation outlet of the second separator 2 is connected to the middle part of...

Embodiment 3

[0037] Based on the filtering system of the separating device of embodiment 2, its filtering method:

[0038] Step 1: The oil at the top and bottom of the oil tank body 3 is mixed evenly through the pipeline at a ratio of 1.3-1.8, and the mixed oil is sprayed into the first separator 1 at a speed of 15-18m / s under the action of the oil pump In the quality area, after the oil is fully decelerated under the action of the buffer strip, the heavy impurities in the oil fall to the heavy area, and the light impurities in the oil float up to the light area;

[0039] Step 2: The oil after impurity separation enters the second separator 2 through the separation outlet, and the oil in the heavy area enters the first filter 5 and flows into the second separator 2 after being filtered by impurities, and the oil in the light area enters the second separator 2. The oil enters the second filter 6 and flows into the second separator 2 after being filtered by impurities;

[0040] Step 3: The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com