Lifting support frame and display appliance

A support frame and utensil technology, which is applied in home utensils, applications, display hangers, etc., can solve the problems of narrow application range and easy damage of support plates, and achieve the effects of saving costs, reducing use costs, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

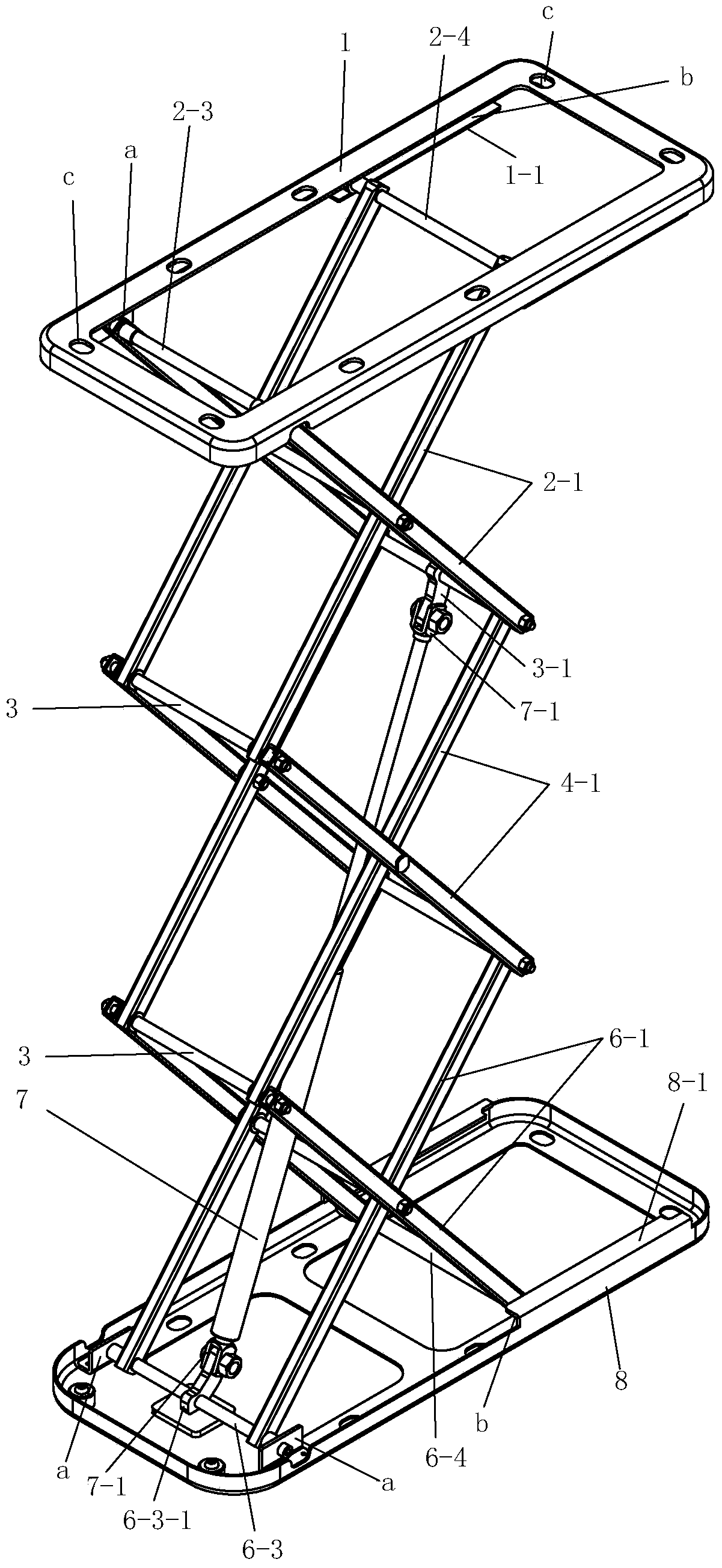

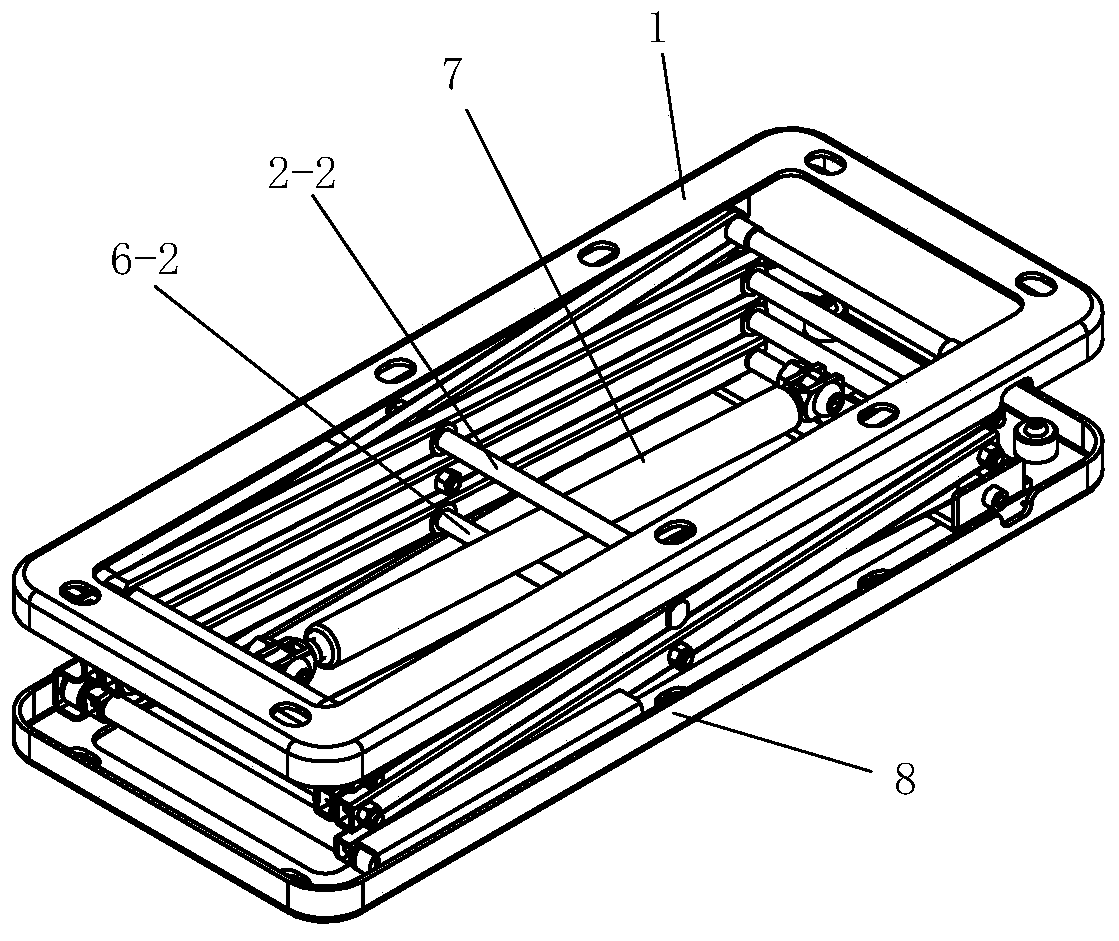

[0028] See Figure 1 to Figure 4 , This embodiment includes an upper connection frame 1, a three-dimensional grid-like lifting platform, a lower connection frame 8 and a power unit. The upper connection frame 1 and the lower connection frame 8 may be circular, elliptical, square, or rectangular, and the upper connection frame 1 or / and the lower connection frame 8 are provided with mounting holes c on the frame edge. The structure of the upper and lower connecting frames is the same. A pair of hinge seats a and a pair of guide grooves b are respectively provided at both ends of the connection frame. Formed by bending at right angles. The upper and lower connection frames are arranged symmetrically in a mirror image.

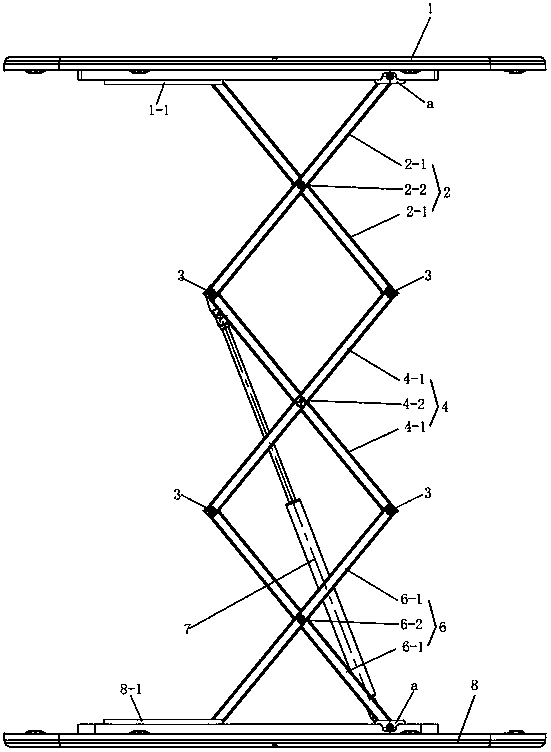

[0029] The three-dimensional grid-like lifting platform is located between the upper connecting frame 1 and the lower connecting frame 8. The three-dimensional grid-like lifting platform of this embodiment has three layers of grid units, which are respectively t...

Embodiment 2

[0036] See Figure 5 , the three-dimensional grid-like elevating platform of Embodiment 2 has four layers of grid units, namely an upper grid unit 2, a lower grid unit 6 and two middle grid units 4. Two pairs of connecting rods 4-1 of an intermediate grid unit 4 adjacent to the lower grid unit 6 are each hinged on the short pin shaft 4-2, that is, the lower intermediate grid unit 4 of the two intermediate grid units Each of the two pairs of connecting rods 4-1 is hinged on the short pin shaft 4-2, and the two pairs of middle connecting rods 4-1 of the upper middle grid unit 4 can be respectively hinged on the short pin shaft. The two pairs of middle connecting rods 4-1 of the upper middle grid unit 4 are respectively located at both ends of a middle-length pin shaft 4-3 and are hinged to the middle-long pin shaft 4-3. All the other are identical with embodiment 1. This structure is adopted for the three-dimensional grid-shaped lifting platform with more than four layers of g...

Embodiment 3

[0038] See Image 6 , the three-dimensional grid-like lifting platform of embodiment 3 has two layers of grid units, namely the upper grid unit 2 and the lower grid unit 6, one end of the gas spring 7 is hinged on the lower positioning rod 6-3, and the other end is hinged on the upper On the guide rod 2-4. All the other are identical with embodiment 1.

[0039] In the above-mentioned embodiments 1 to 3, the connection of the gas spring 7 can be that one end is hinged on the lower positioning rod 6-3, and the other end is hinged on the lower guide rod 6-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com