Linear wrapper-connection compact stuffed food forming machine

A compact, forming machine technology, applied in dough forming and cutting equipment, food science, dough sheeter/roller/rolling pin, etc., to achieve the effect of reducing volume, reducing transportation and circulation links, and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

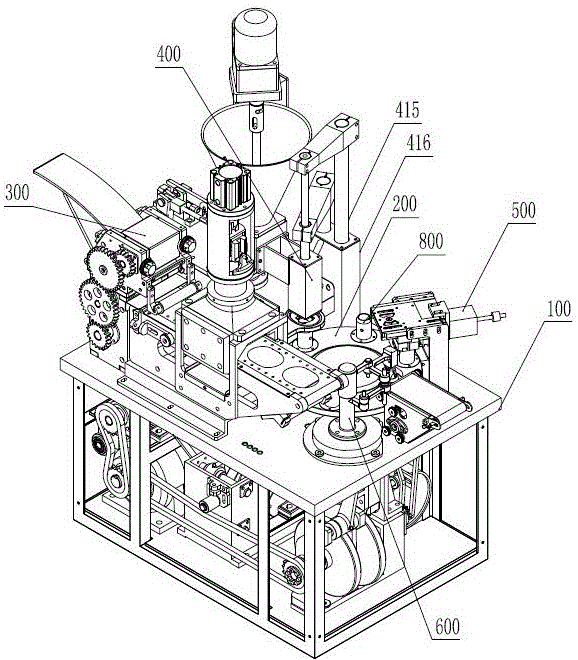

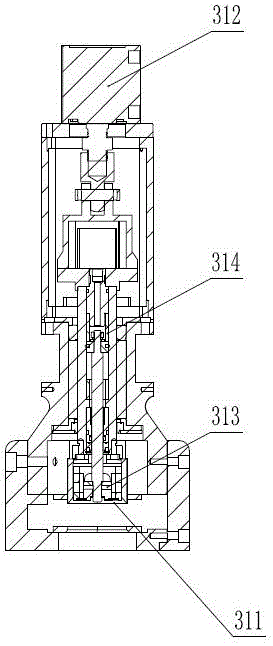

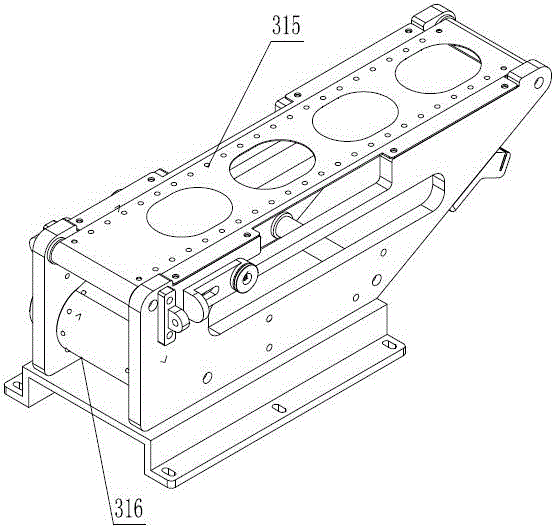

[0083] The compact stuffed food forming machine for straight-line skinning includes a frame 100 and a station turntable 200 located on the frame 100. A leather making device 300, a filling device 400, and a pressing device 500 are respectively arranged around the station turntable 200. And discharging device 600, described leather-making device 300 places are leather-making station, filling device 400 places are filling station, pressing device 500 places are pressing station, discharging device 600 places are discharging station; The frame 100 is also provided with a split-type molding die, the split-type molding die includes a linear skin-joint plate 700 and a mold cup 800 that are independent of each other, and a center for forming is provided on the linear skin-joint plate 700 The hole 702, the linear connecting plate 700 is connected with a translation column 704 that drives it to do horizontal reciprocating motion, and the translation column 704 is connected with the driv...

Embodiment 2

[0089] The compact stuffed food forming machine for straight-line skinning includes a frame 100 and a station turntable 200 located on the frame 100. A leather making device 300, a filling device 400, and a pressing device 500 are respectively arranged around the station turntable 200. And discharging device 600, described leather-making device 300 places are leather-making station, filling device 400 places are filling station, pressing device 500 places are pressing station, discharging device 600 places are discharging station; The frame 100 is also provided with a split-type molding die, the split-type molding die includes a linear skin-joint plate 700 and a mold cup 800 that are independent of each other, and a center for forming is provided on the linear skin-joint plate 700 The hole 702, the linear connecting plate 700 is connected with a translation column 704 that drives it to do horizontal reciprocating motion, and the translation column 704 is connected with the driv...

Embodiment 3

[0096] The compact stuffed food forming machine for straight-line skinning includes a frame 100 and a station turntable 200 located on the frame 100. A leather making device 300, a filling device 400, and a pressing device 500 are respectively arranged around the station turntable 200. And discharging device 600, described leather-making device 300 places are leather-making station, filling device 400 places are filling station, pressing device 500 places are pressing station, discharging device 600 places are discharging station; The frame 100 is also provided with a split-type molding die, the split-type molding die includes a linear skin-joint plate 700 and a mold cup 800 that are independent of each other, and a center for forming is provided on the linear skin-joint plate 700 The hole 702, the linear connecting plate 700 is connected with a translation column 704 that drives it to do horizontal reciprocating motion, and the translation column 704 is connected with the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com