Phosphorus-contained negative electrode composite material and preparation method therefor, and lithium ion battery

A composite material and negative electrode technology, which is applied in the field of phosphorus-containing negative electrode composite materials and its preparation, and lithium-ion batteries, can solve the problems of difficult morphology, difficult preparation of red phosphorus, and easy agglomeration, and achieve the goal of improving the reversibility of electrochemical lithium storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

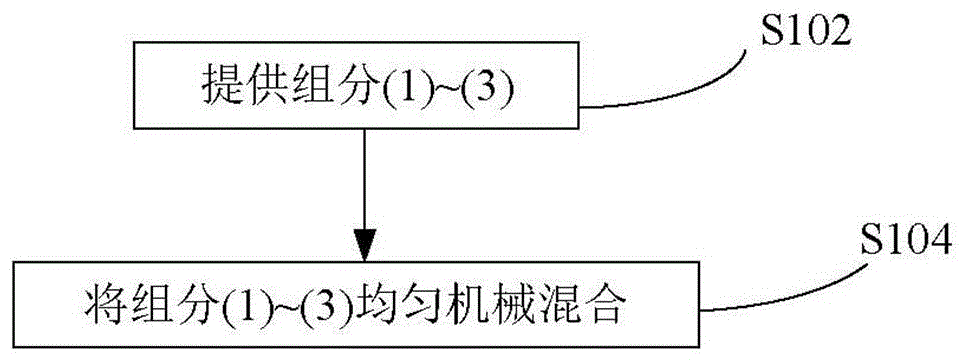

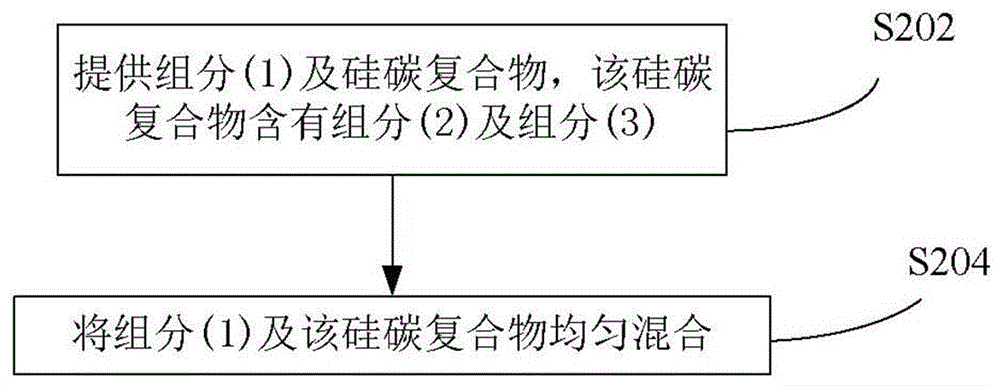

[0039] see figure 1 , the embodiment of the present invention provides the preparation method 100 of the above phosphorus-containing negative electrode composite material, comprising the following steps:

[0040] S102, providing the above components (1)~(3); and

[0041] S104, uniformly mechanically mixing the above components (1)-(3).

[0042] In the step S104, the components (1)-(3) can be directly stirred and mixed uniformly, the components (1)-(3) are solid particles, and the mixing temperature can be normal temperature. In the step S104, the phosphorus-containing negative electrode composite material can be obtained after uniformly mixing the components (1)-(3), that is, it is not necessary to perform high-temperature heat treatment on the mixed material.

[0043] This mixing step can be simple mechanical mixing, for example, it can be mixed by rotating an electric stirring paddle in a container with the above components (1)-(3), or even can be stirred and mixed by a ha...

Embodiment 1

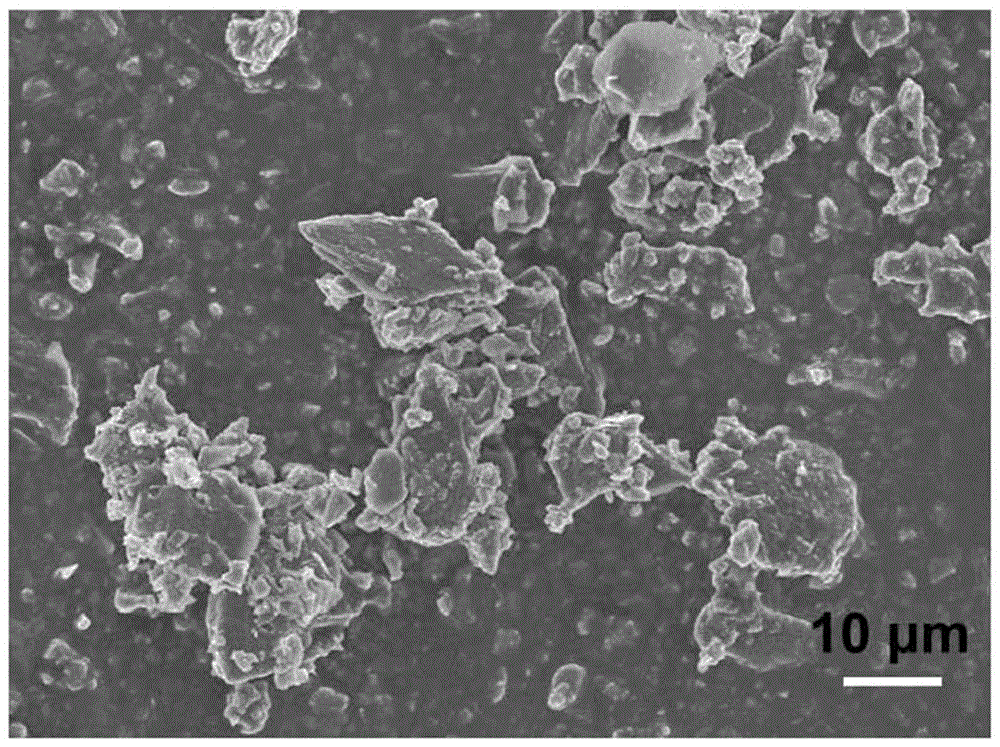

[0063] see image 3 and Figure 4 and uniformly mixing elemental silicon particles, activated carbon particles and red phosphorus particles to form the phosphorus-containing negative electrode composite material. The mass percentage of the activated carbon in the phosphorus-containing negative electrode composite material is about 47.5%. The mass percentage of the red phosphorus in the phosphorus-containing negative electrode composite material is about 50%. The mass percentage of the elemental silicon in the phosphorus-containing negative electrode composite material is about 2.5%. The average particle size of the red phosphorus particles is about 2 microns. The average particle size of the activated carbon is about 5 microns. from Figure 4 It can be seen that the three elements of carbon, silicon and phosphorus are basically evenly distributed after mixing.

[0064] The phosphorus-containing negative electrode composite material is used as a negative electrode active ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com