Granary sampler

A sample divider and granary technology, applied in the preparation of test samples, etc., can solve the problems of test result deviation, uneven distribution, easy to produce objective errors, etc., to reduce errors, avoid errors and deliberate, scientific sampling work and rigorous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

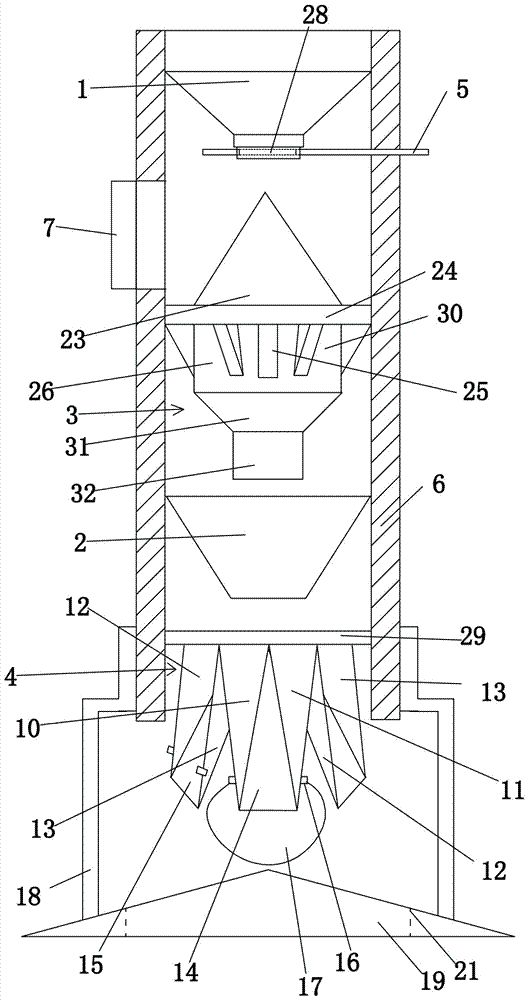

[0048] The granary sample divider includes a sample divider 6.

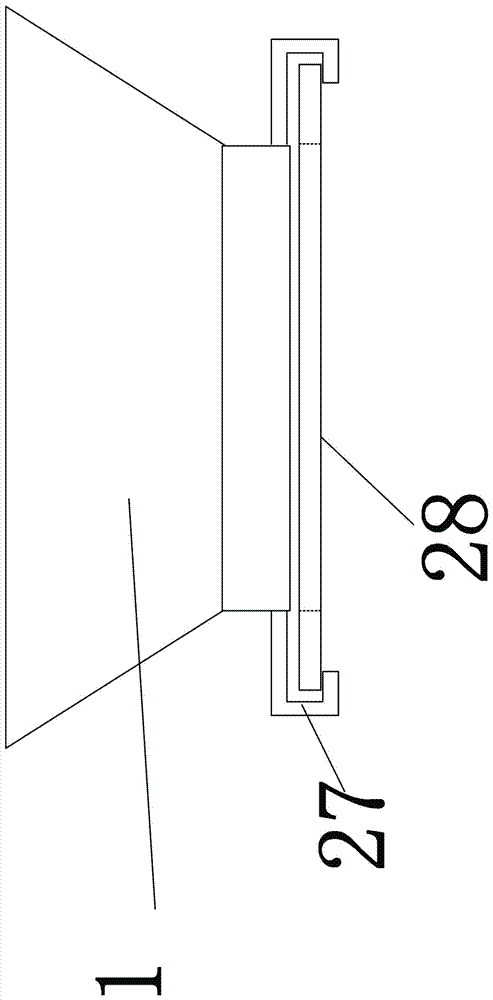

[0049] The sample dividing cylinder 6 includes a first funnel 1 , a first sample dividing body 3 , a second funnel 2 and a second sample dividing body 4 sequentially from top to bottom. The sample-dividing cylinder 6 is a cylindrical shape with upper and lower openings.

[0050] The outlet of the first funnel 1 is located above the tip of the first sample dividing body 3 .

[0051] The first sub-sample 3 is a Canadian sub-sample, which is a known technology.

[0052] The upper end of the first dividing body 3 is a conical casing 23, the lower end of the conical casing 23 is connected to the first cylindrical casing 26, and the lower end of the first cylindrical casing 26 is connected to the second cylinder through a frustum-shaped casing 31 Type shell 32. The diameter of the first cylindrical shell 26 is larger than that of the second cylindrical shell 32 .

[0053] The insides of the conical housing 23 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com