Construction and manufacturing process of total-prefabricated superimposed assembly type underground pipe gallery

A technology of integrated pipe gallery and underground pipe gallery, applied in the field of municipal engineering, can solve the problems of high construction cost, low production efficiency, large amount of earthwork excavation, etc., and achieves less on-site workload, less labor demand, and fast construction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

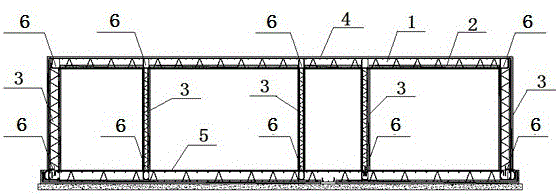

[0039] Referring to the accompanying drawings, the fully prefabricated laminated and assembled underground comprehensive pipe gallery of the present invention has a prefabricated laminated floor as its bottom plate, its side walls or side walls and intermediate walls are prefabricated sandwich laminated walls, and its roof is a prefabricated laminated roof. , The base plate, side wall or side wall, the middle wall, and the roof are connected by cast-in-place to form a whole underground comprehensive pipe gallery.

[0040] The construction process of the above-mentioned fully prefabricated and assembled underground comprehensive pipe gallery includes:

[0041] 1) Excavation of underground pipe gallery;

[0042] Excavate the foundation pit of the underground pipe gallery slightly wider than the width of the underground pipe gallery, and prepare retaining walls on both sides of the foundation pit of the underground pipe gallery;

[0043] 2) Lay the cushion on the foundation pit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com