Control support frame applied to high-torque rotary jet mixing pile construction device

A technology of construction device and mixing pile, which is applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problem of inability to meet the high standard quality requirements of pile arrangement, reduce the efficiency and quality of pile arrangement construction, and increase the consumption of concrete raw materials, etc. It can meet the requirements of stable support and efficient adjustment of construction, ensure safety and stability of construction quality, and solve the effect of low adjustment efficiency.

Inactive Publication Date: 2016-08-10

JIANGSU CHANGXIN BASIC ENG

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Purpose of the invention: The purpose of the present invention is to provide a control support frame applied to the construction device of large-torque rotary spraying and mixing piles, so as to solve the problem of time-consuming adjustment and unreliable positioning after adjustment in the complex construction of the existing structure, thereby reducing the construction work of laying piles. Efficiency and quality cannot meet the high standard quality requirements of the piles. When the error is large and rework is required, it not only reduces the construction progress but also increases the consumption of concrete raw materials. Its design is reasonably controlled, accurate, stable and efficient

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

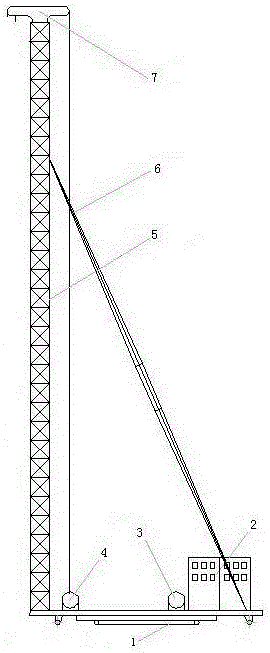

[0016] further as figure 1 , when adjusting the operation, use the power distribution operation room 2 to control the main rotary hoist 3 to rotate counterclockwise or clockwise, and the main rotary hoist 3 to rotate counterclockwise or clockwise to drive the connecting rope passing through the three door pulley 4 to control the horizontal The head slider 7 rises or falls, finally realizing precise, efficient and stable control.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of application of building construction foundation drill fittings, and in particular, discloses a control support frame applied to a high-torque rotary jet mixing pile construction device. The control support frame comprises an automatic walking car, a power distribution operation chamber and a pulley arranged on the automatic walking car, a main windlass arranged on the automatic walking car and positioned between the power distribution operation chamber and the pulley, a well frame arranged on the automatic walking car and positioned on the outer side of the pulley, a frame support rod respectively connected with the well frame through two ends, and a horizontal head slide piece arranged on the well frame. The control support frame has the following beneficial effects: the purpose of efficiently and precisely controlling and adjusting a drill rod and a drill bit is realized; the positioning is firm after adjustment; the pile distribution construction safety and the construction quality stability are effectively guaranteed; the phenomenon of low adjusting efficiency of a traditional high-torque rotary jet mixing pile construction device and unstable support of a whole support structure is solved; the requirements of stable support and efficient construction adjustment are satisfied; the raw materials are saved; and the production cost is reduced.

Description

technical field [0001] The invention belongs to the technical field of application of drilling tool accessories for building construction foundations, and in particular relates to a control support frame applied to a construction device of a high-torque jet-jet mixing pile, capable of stably, accurately and efficiently controlling the completion of the drill assembly of the construction device of a high-torque jet-jet mixing pile Pile construction work. Background technique [0002] High-pressure rotary grouting piles use high-pressure rotating nozzles to spray cement slurry into the soil layer and mix with the soil to form a continuous lapped cement reinforcement. Its construction operations require less land, less vibration, and lower noise, which are preferred by most construction units. use. The jet grouting method, also known as the jet grouting method, referred to as the jet grouting pile, emerged in the 1970s as a high-pressure jet grouting method, and was fully deve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E02D5/46E02D15/02

CPCE02D5/46E02D15/02

Inventor 徐其新徐涵杨姣孙鸿林梁龙标沈宇浈江涛明刚

Owner JIANGSU CHANGXIN BASIC ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com