Spinning thread oiling device

A technology of textile thread and oil storage tank, which is applied in textiles and papermaking, can solve problems such as excessive oiling, and achieve the effects of protecting the environment, promoting and utilizing value, and improving the effect of elastication.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

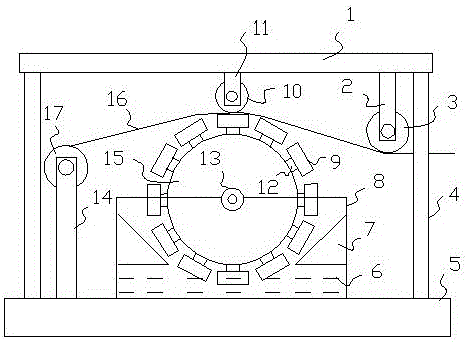

[0020] Such as figure 1 , figure 2 As shown, the oiling device on this kind of textile line has a structure comprising a base 5, the top of the base 5 is vertically provided with a support 14 near the left side, and the top of the support 14 is provided with a pay-off roller 17; the base on the right side of the support 14 5 is provided with an oil storage tank 8, the upper edge of the oil storage tank 8 is provided with a winding roller 15 through the rotating shaft 13, and the outer surface of the winding roller 15 is provided with a sponge block 9 through several bearings 12. When in use, inject oil into the oil storage tank, turn the sponge block at the bottom of the winding roller to contact with the oil, then the oil will be immersed in the sponge block, and the textile thread will be pulled out fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com