Mud-water separation apparatus and mud-water separation method

A mud-water separation and equipment technology, which is applied in the field of mud-water separation equipment and mud-water separation, can solve the problems of ineffective control, increased energy consumption and cost, and large amount of flocculant, so as to increase the mud dehydration effect, save construction costs, and achieve large-scale treatment volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

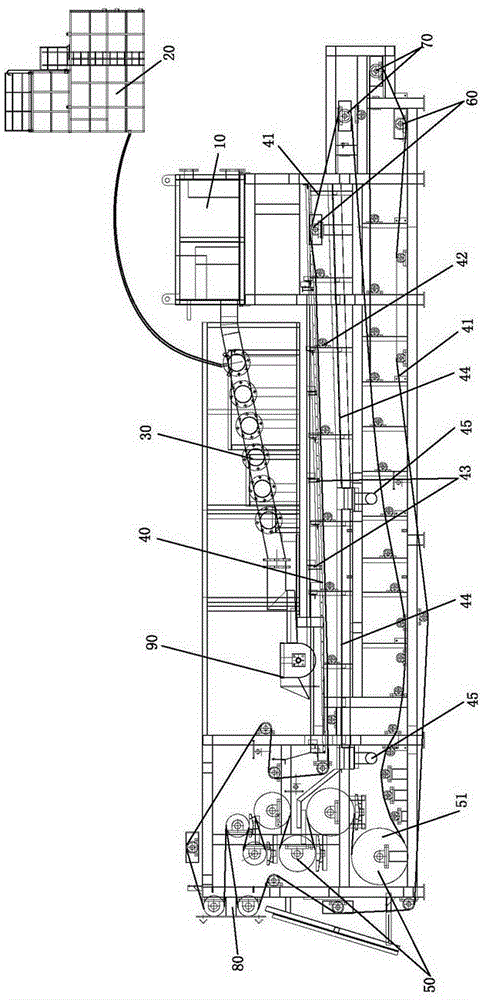

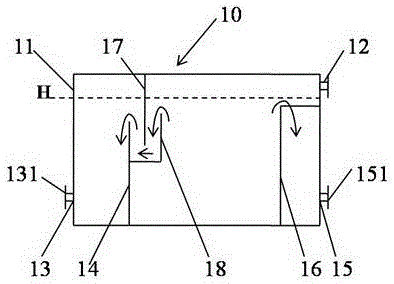

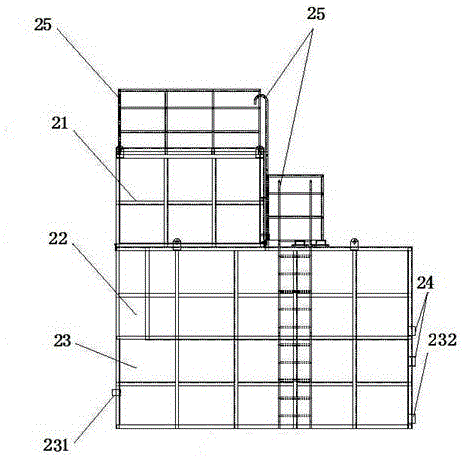

[0043] Such as figure 1 As shown, the pressure and flow stabilization device 10, the dosing box 20, the flocculation device 30, the homogeneous leveling device 90, and the concentration and dehydration device 40 in the mud-water separation device are successively arranged on the frame from high to low. The mud can complete the preliminary dehydration through the above-mentioned processes sequentially by its own gravity, and enter the pressure dehydration device 50 from the concentration dehydration device 40 . The mud outlet 13 of the pressure and flow stabilization device 10 is connected to a flocculation device 30 . The mixed medicine in the medicine adding box 20 enters the flocculation device 30 from the flocculant conveying p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com