A sleeve-type freshwater sea-salt cogeneration system

A telescopic, fresh water technology, applied in seawater treatment, ocean energy power generation, water/sewage treatment, etc., can solve the problem of neglecting the utilization of sea salt, and achieve the effect of reducing seawater concentration time, compact structure and high output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

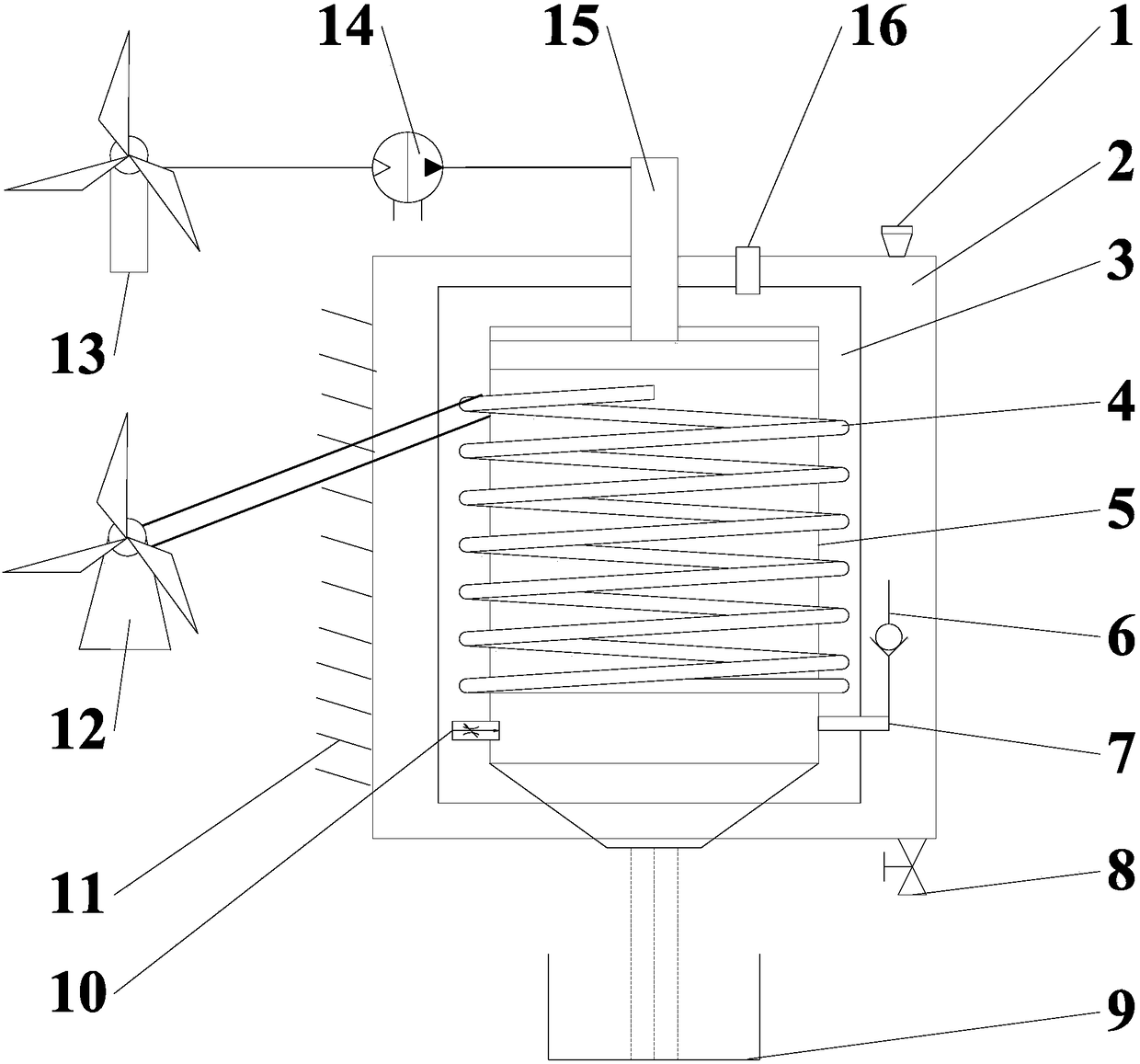

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, a sleeve-type freshwater and sea-salt cogeneration system includes a heating cylinder 5 , a seawater storage layer 3 and a freshwater storage layer 2 . A sealed piston 15 that can reciprocate up and down is installed on the top of the heating cylinder 5. Two holes are distributed below the heating cylinder 5. One hole is the seawater inlet and the other is the water vapor outlet 7. The bottom of the heating cylinder 5 is made into a funnel shape that can be unloaded. structure. The seawater storage layer 3 wraps the heating cylinder 5, wherein electric heating wires 4 are densely distributed in the circumferential direction. The flow control valve 10 is connected with the heating cylinder 5 , and the steam outlet 7 is connected with the one-way valve 6 . The freshwater storage layer 2 wraps the seawater storage layer 3 .

[0018] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com