Roller type tightening and heat sealing device

A heat-sealing device and roller technology, applied in packaging, transport packaging, transportation and packaging, etc., can solve the problems of packaging efficiency, inability to wrap clothes in plastic film bags, unfavorable streamlined production, etc., and achieve the effect of compact packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

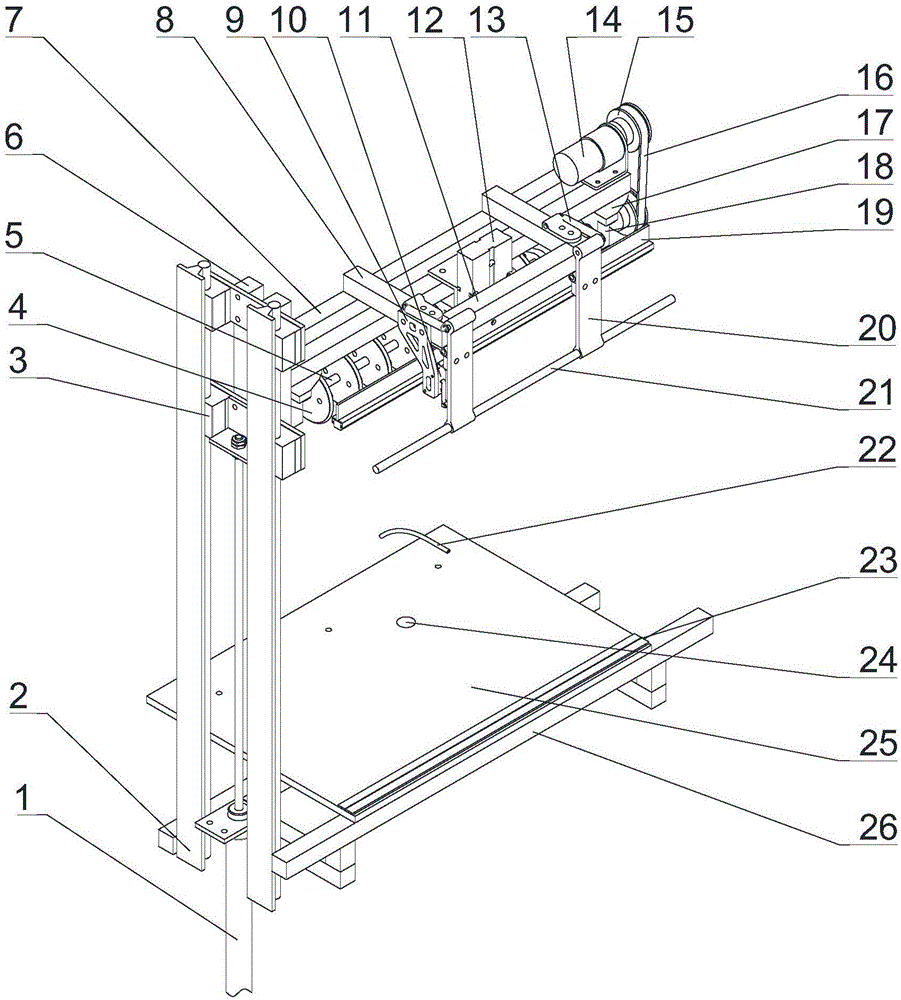

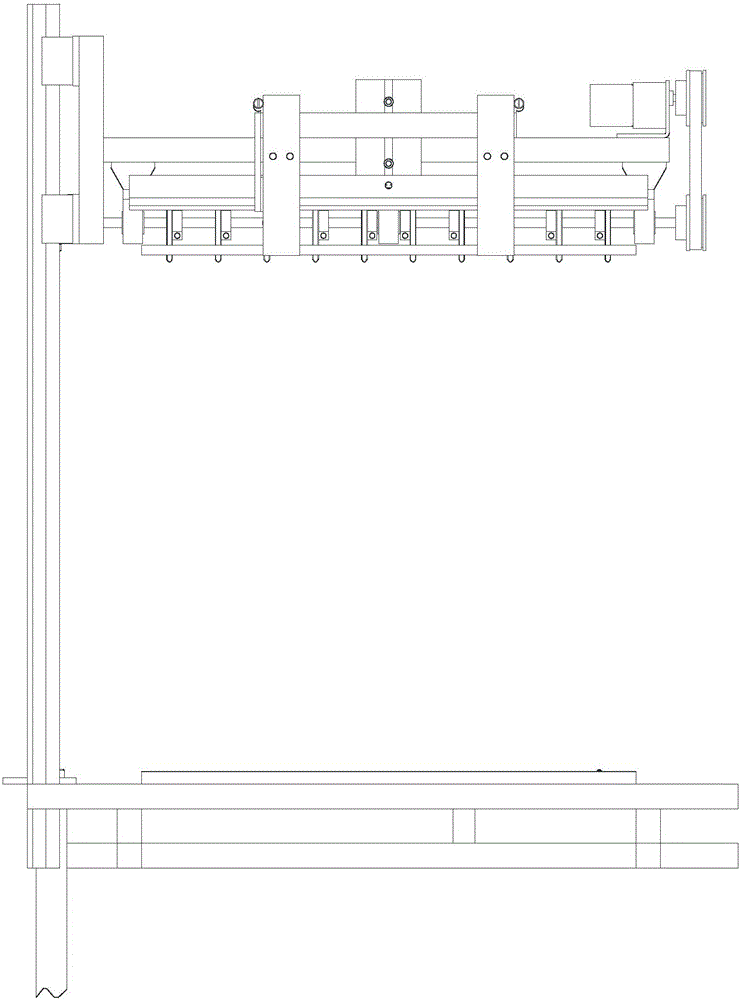

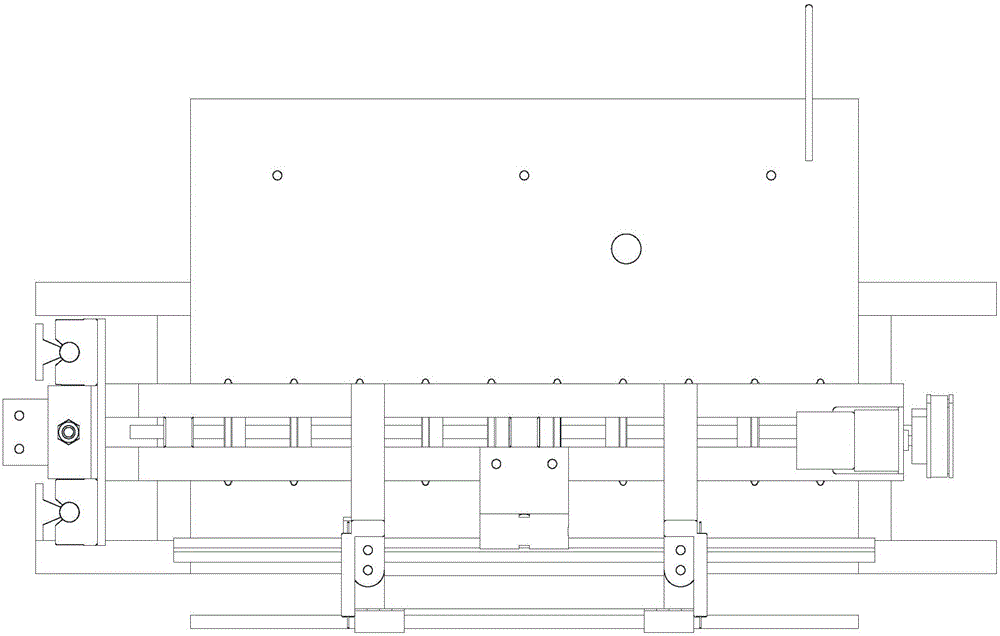

[0014] Such as figure 1 , 2 . As shown in 3, a stick-type tightening heat-sealing device includes a main frame 26, a roller frame, moving parts, a roller assembly, and a heat-sealing assembly. The roller parts and heat-sealing components are installed on the roller frame, The roller frame is connected to the moving parts;

[0015] The main frame 26 is a frame for fixing the whole device, which is built from industrial aluminum profiles;

[0016] The roller frame is composed of two cantilever longitudinal beams 6, two cantilever horizontal beams 7, two heat-sealed longitudinal beams 8, and a heat-sealed beam 11; the cantilever longitudinal beams 6 are vertically arranged, and each cantilever longitudinal beam 6 A cantilever horizontal beam 7 is horizontally arranged at the midpoint; a heat-sealed longitudinal beam 8 is arranged at the quarter point o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com