An industrial separation equipment

A separation equipment, industrial technology, applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of polluting the environment, high energy consumption, etc., and achieve simple operation, reduced operating costs, and high control accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

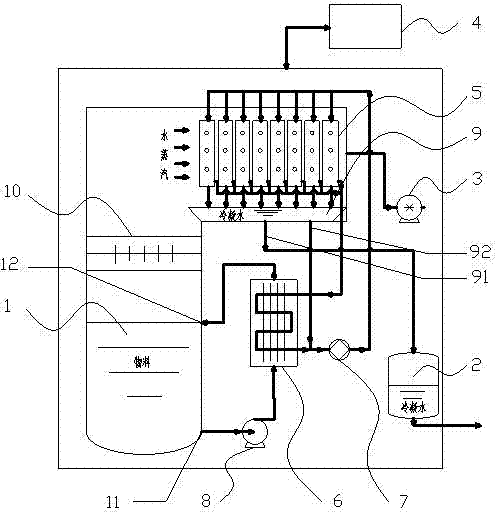

[0045] Such as figure 1 As shown, an industrial separation equipment includes a vacuum separation tank 1, a condensed water recovery tank 2, a vacuum pump unit 3, a molecular compression mechanism 5, a heat exchanger 6, a multistage booster pump 7 and a forced circulation pump 8.

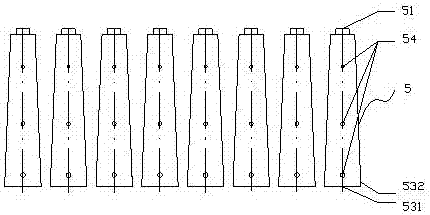

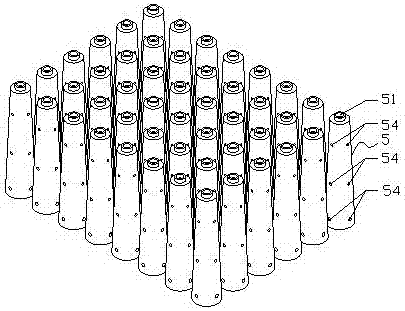

[0046] In order to increase the water vapor intake rate of the molecular compression mechanism 5, as figure 2 , image 3 and Figure 4 As shown, there are 48 molecular compression mechanisms 5 arranged in a matrix of 6 rows and 8 columns. Such as Figure 5 , Figure 6 and Figure 7As shown, the top of the molecular compression mechanism 5 is provided with a condensed water inlet port 51, which is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com