Evolving tyre tread

A tread, tire technology, applied in the direction of tire tread/tread pattern, heavy-duty tires, tire parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

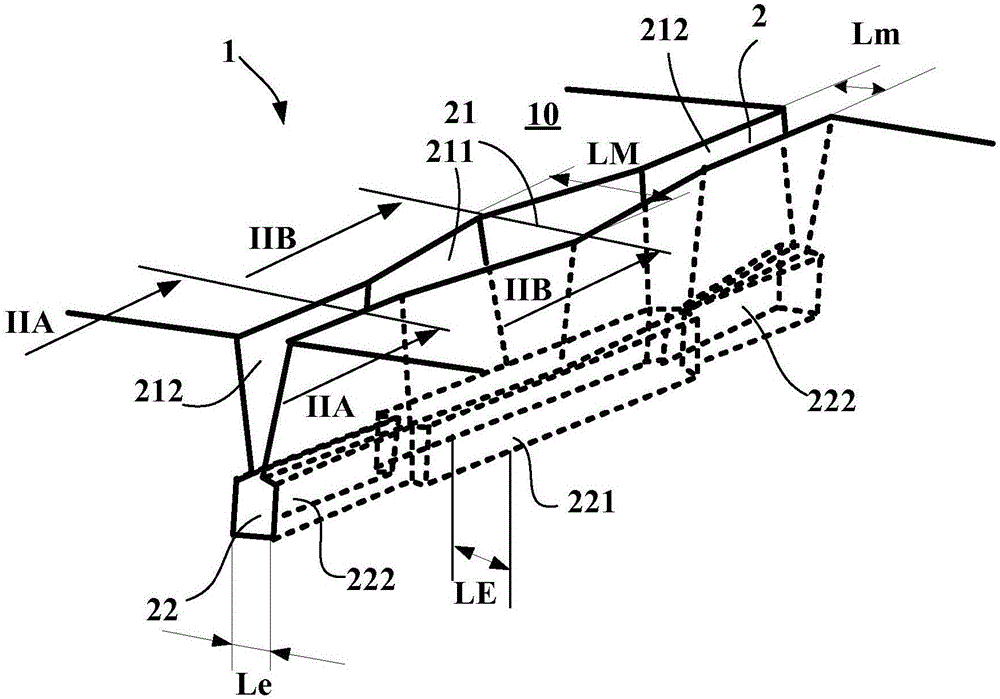

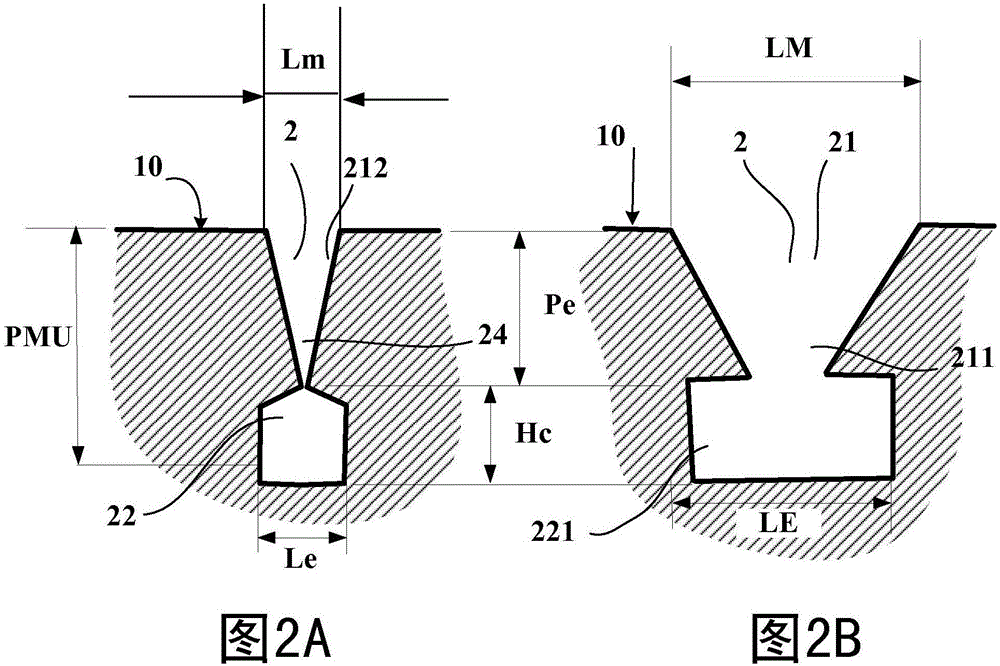

[0032] figure 1 Shown is part of a cutout according to the invention in a tread intended to be fitted to a heavy vehicle tire of size 315 / 70R22.5.

[0033] When the tread 1 is brand new (such as figure 1 ) comprises a tread surface 10 intended to contact the road during running.

[0034]Incisions 2 oriented along the main direction lead to this tread surface 10 . This cutout 2 extends down into the thickness of the tread and to a depth greater than the maximum thickness PMU of the material to be worn away during running. This maximum thickness PMU is in this case equal to 14.5 mm. In this figure, it can be seen that the total depth of the grooves is greater than the thickness PMU of the material to be worn away, so that the good performance, especially in terms of drainage in rainy weather, is maintained until corresponding to said depth degree of wear and tear.

[0035] The cutout 2 comprises, on its outer part, ie the part radially towards the outside, a groove 21 whose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com