Method for applying uranium recycled from pressurized water reactor to heavy water reactor

A technology for recovering uranium and heavy water reactors, applied in reactors, manufacturing reactors, reducing greenhouse gases, etc., can solve the problems of no fuel demonstration or engineering application examples, high core conversion costs, high fuel manufacturing costs, etc., to achieve reduction Fuel cost, economical and efficient utilization, avoiding the effect of high radioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] According to recovered uranium 235 The enrichment degree of U is higher than that of natural uranium. Depleted uranium (DU) is mixed with recycled uranium. By accurately adjusting the mixing ratio of recycled uranium and depleted uranium, the nuclear characteristics of the mixture are equivalent to natural uranium fuel. This mixture is hereinafter referred to as equivalent natural uranium. The invention uses equivalent natural uranium to replace the natural uranium, and produces the fuel for the heavy water reactor on the fuel production line of the heavy water reactor.

[0040] Specific steps are as follows:

[0041] (1) Use a mass spectrometer to measure the metallic uranium content, uranium isotopic composition and / or uranium isotopic distribution in recovered uranium and depleted uranium;

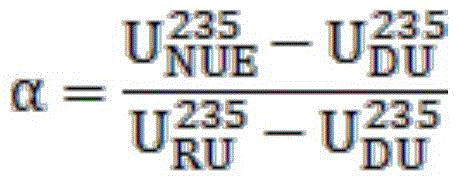

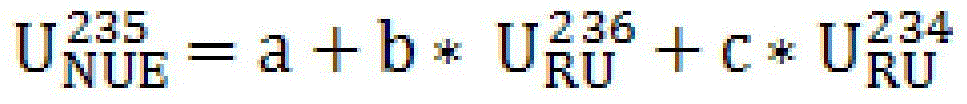

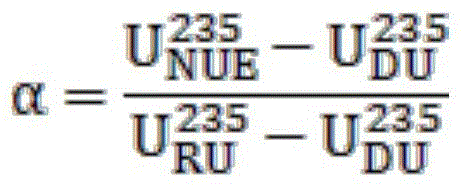

[0042] (2) According to the uranium isotope composition of recovered uranium and depleted uranium in step (1), use the formula to calculate the mixing ratio α and 1-α of recove...

Embodiment 2

[0053] The invention uses equivalent natural uranium to replace the natural uranium, and produces the fuel for the heavy water reactor on the fuel production line of the heavy water reactor.

[0054] Specific steps are as follows:

[0055] (1) Use a mass spectrometer to measure the metallic uranium content, uranium isotopic composition and / or uranium isotopic distribution in recovered uranium and depleted uranium;

[0056] (2) According to the uranium isotope composition of recovered uranium and depleted uranium in step (1), use the mixture calculation program developed based on neutronics calculation program WIMS-AECL, or WIMS-D, or MCNP calculation to achieve the same ratio as natural Uranium equivalent recycled uranium and depleted uranium mixing ratio α and 1-α, 0<α≤1 and NUE target value;

[0057] (3) Accurately weighing the recovered uranium and depleted uranium according to the ratio described in step (2), and then physically mixing them to form equivalent natural uran...

Embodiment 3

[0063] The invention uses equivalent natural uranium to replace the natural uranium, and produces the fuel for the heavy water reactor on the fuel production line of the heavy water reactor.

[0064] Specific steps are as follows:

[0065] (1) Use a mass spectrometer to measure the metallic uranium content, uranium isotopic composition and / or uranium isotopic distribution in recovered uranium and depleted uranium;

[0066] (2) According to the uranium isotope composition of recovered uranium and depleted uranium in step (1), the mixing ratio α and 1-α of recovered uranium and depleted uranium equivalent to natural uranium are calculated by using a mixture calculation program, 0<α≤1 and NUE target value;

[0067] The mixture calculation program is a computer program developed based on the calculation of the neutronics calculation program WIMS-AECL, or WIMS-D, or MCNP.

[0068] (3) Accurately weigh the recovered uranium and depleted uranium according to the ratio described in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com