Rapid construction method for deep hole blasting of vertical shaft frozen bedrock

A construction method and deep-hole blasting technology, which is applied in blasting and other directions, can solve the problems of shortened construction period, high cost, and long construction period, and achieve the effects of short drilling process time, improved work efficiency, and protection of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

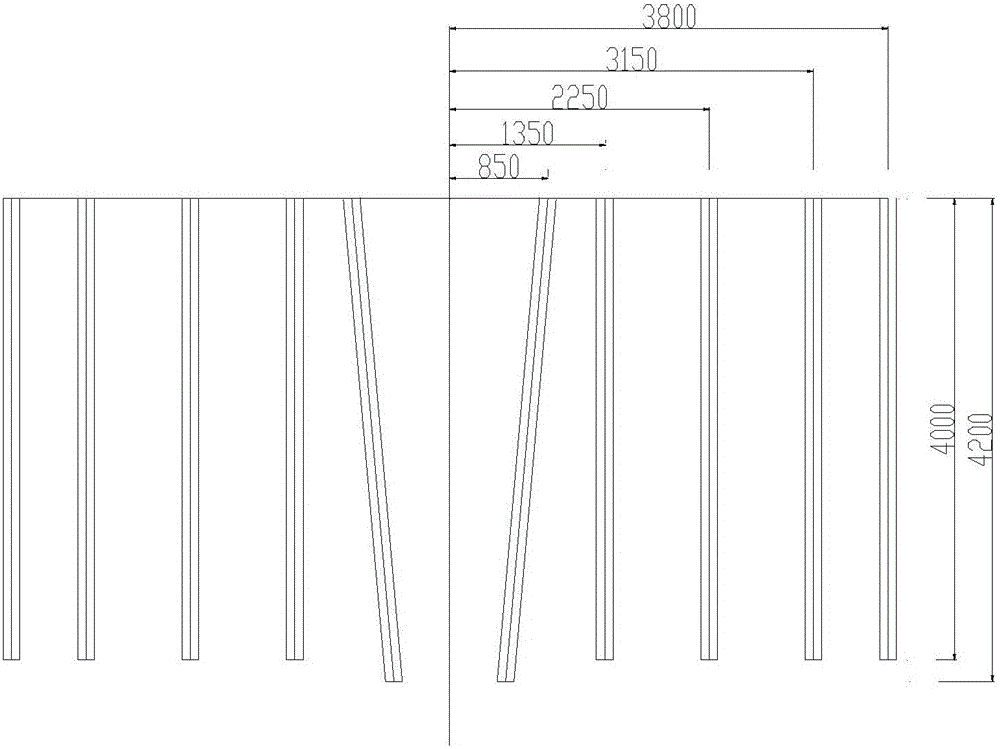

[0021] A rapid construction method for deep-hole blasting in frozen bedrock of a shaft, in particular to a construction method for rapid excavation of deep-hole blasting in deep holes around the bedrock after the shaft is frozen without affecting the safe operation of a frozen layer or a frozen pipe . The utility model is characterized in that: it overcomes the shortcomings of low efficiency, long construction period and high cost caused by shallow hole blasting which is generally only used for freezing bedrock in the shaft, thereby providing a construction method for deep hole differential blasting in bedrock matched with the shaft freezing method. In this method, a deep hole is formed during one drilling, and the peripheral hole is divided into a charging structure to form a peripheral eye charging structure, so as to achieve differential smooth blasting in the hole, thereby reducing blasting vibration and effectively protecting the safety of the freezing pipe and the freezin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com