Internal expansion type rubber sealing ring and application thereof

A rubber sealing ring, rubber sealing technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the problems of large pipeline plugging workload, unusable sealing rings, large investment, etc., to achieve plugging Good effect, improved sealing effect, short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

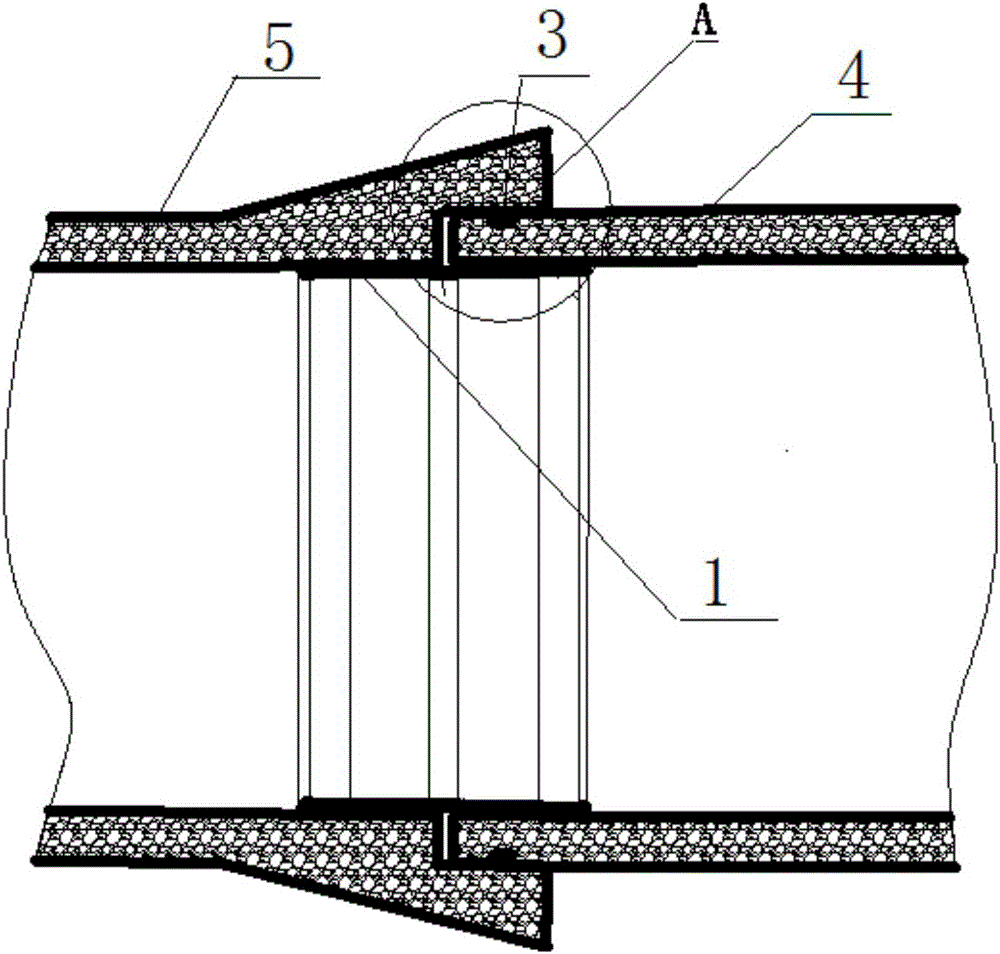

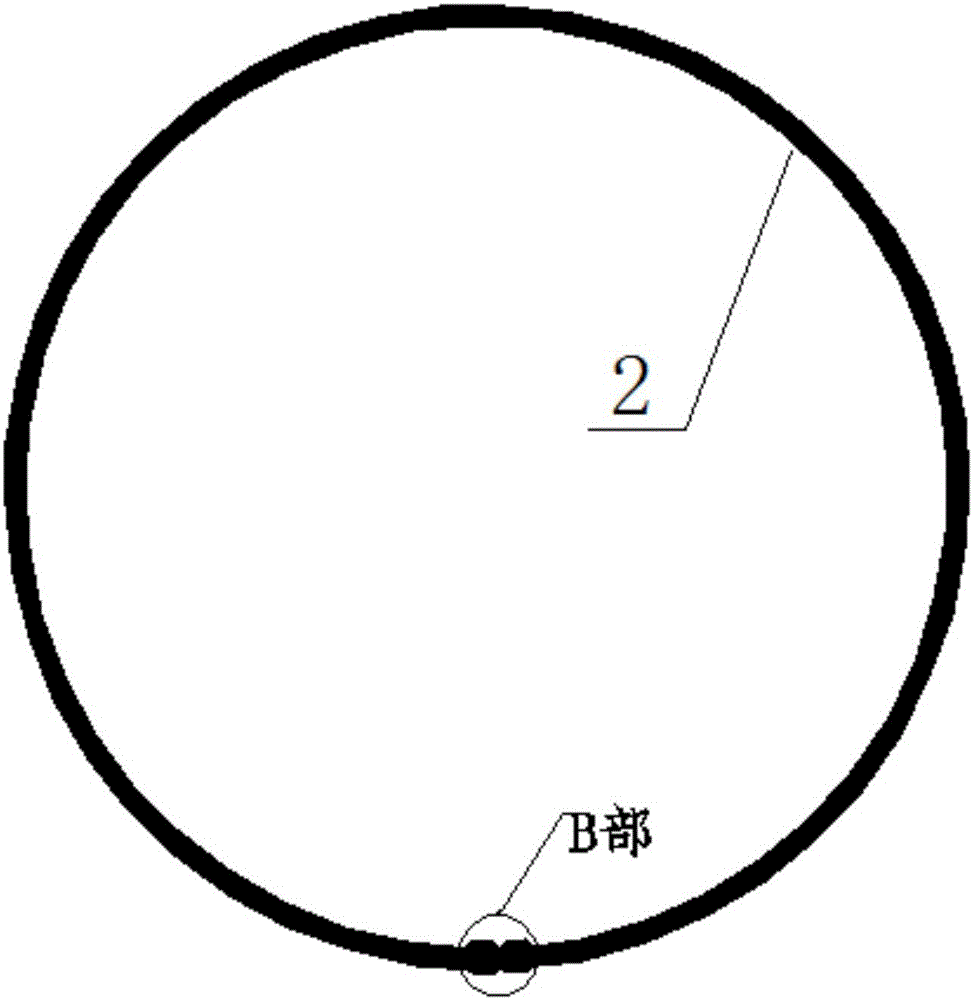

[0040] Such as figure 1 with 2 As shown, an internally expanding rubber sealing ring in this embodiment includes a rubber sealing ring 1 and an internally expanding steel ring 2. The rubber sealing ring 1 is applied to the gap formed after the pipe socket 4 is inserted into the pipe socket 5. Its width is 10cm, and its diameter is 110cm. The inner diameter of the pipe socket 4 is 120cm; the diameter of the inner expansion steel ring 2 is 120cm, which is close to the inner wall of the rubber seal ring 1 to form an inner expansion structure.

[0041] The municipal staff of a certain city found that there were water leaks at all the sockets of the DN1200 prestressed concrete pipeline of nearly 3 kilometers. After analysis, since the pipeline was laid ten years ago, if figure 1 As shown, the sealing is completed by setting a ring of sealing ring 3 on the outer edge of the pipe socket 4, and then inserting the pipe socket 4 into the pipe socket 5 to complete the pipe connection. ...

Embodiment 2

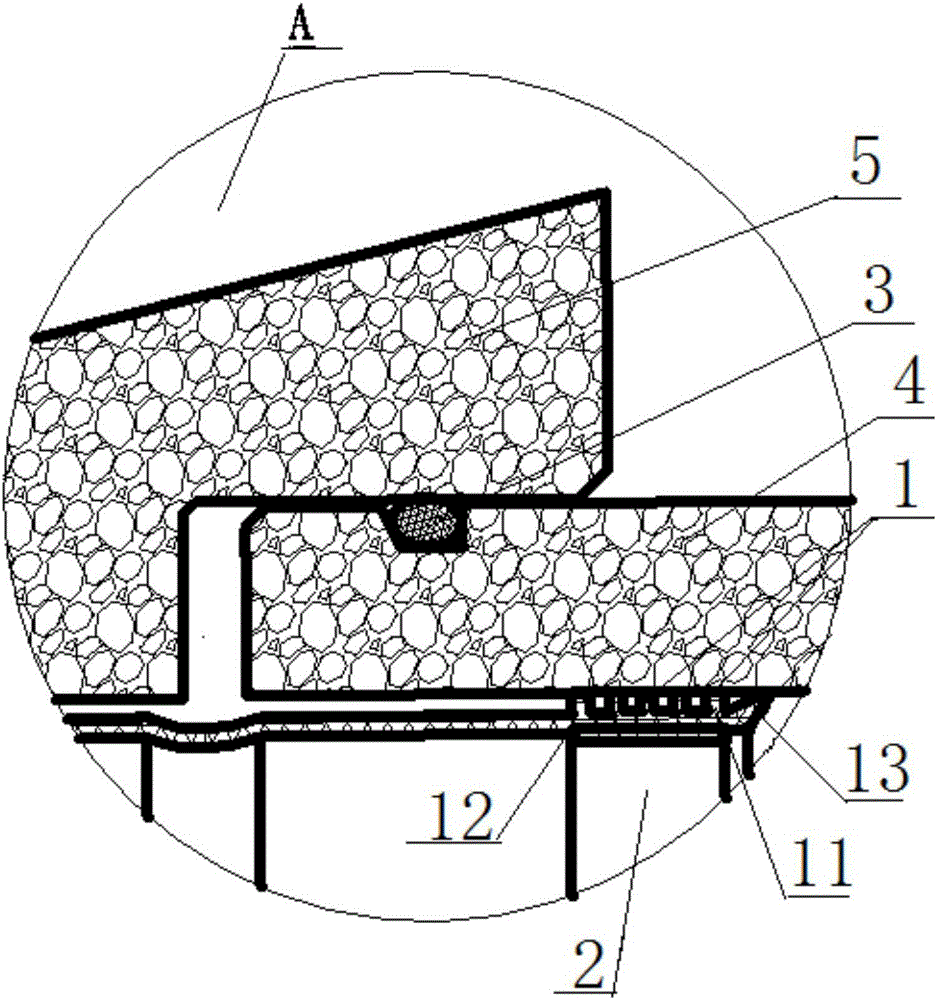

[0047] The basic structure of the internally expanding rubber sealing ring of this embodiment is the same as that of Embodiment 1. The improvement is that there are two internally expanding steel rings 2, each with a width of 50 mm; the width of the rubber sealing ring 1 is 500 mm, and the rubber seal The axial middle part of the belt ring 1 is close to the gap formed after the pipe socket 4 is inserted into the pipe socket 5, and the inner walls at both ends and the two inwardly expanding steel rings 2 form an inwardly expanding structure, and two sealing bands are formed on both sides of the gap. A groove 12 is arranged on the side close to the rubber sealing ring 1 and the inner expansion steel ring 2, and the inner expansion steel ring 2 is embedded in the groove 12. The width of the inner expansion steel ring 2 is consistent with the width of the groove 12, which can minimize the influence of the left and right movement of the inner expansion steel ring on the sealing effe...

Embodiment 3

[0054] The basic structure of the internal expansion rubber sealing ring of this embodiment is the same as that of embodiment 2, and the improvement is that the material of the rubber sealing ring 1 is diene rubber, the width is 400mm, and the material is preferably EPDM rubber; the internal expansion steel The width of the ring 2 is 50 mm; there are 7 waterstops 11, equivalent to 7 sealing rings, to reduce the impact of the roughness of the inner wall of the pipeline on the sealing effect.

[0055] The application of an internally expanding rubber sealing ring in this embodiment is the same as that in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com