Check valve

A technology of check valve and valve plate, which is applied in the direction of lifting valve, control valve, valve device, etc. It can solve the problems of insufficient pressure, poor sealing, and inability to realize elastic sealing layer, so as to prevent serious wear, improve plugging, Effect of increasing time life and utility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

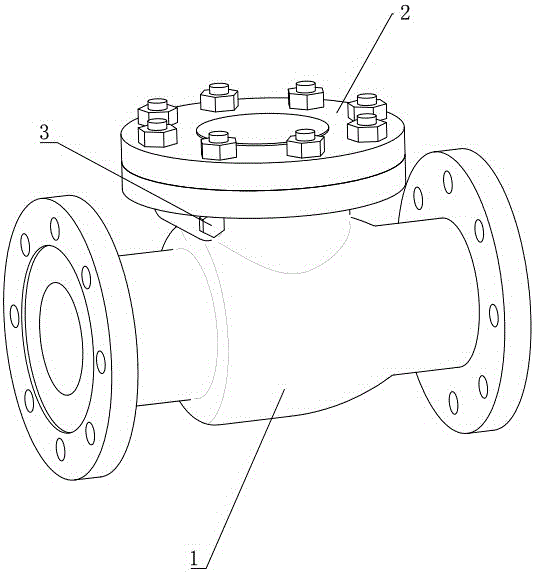

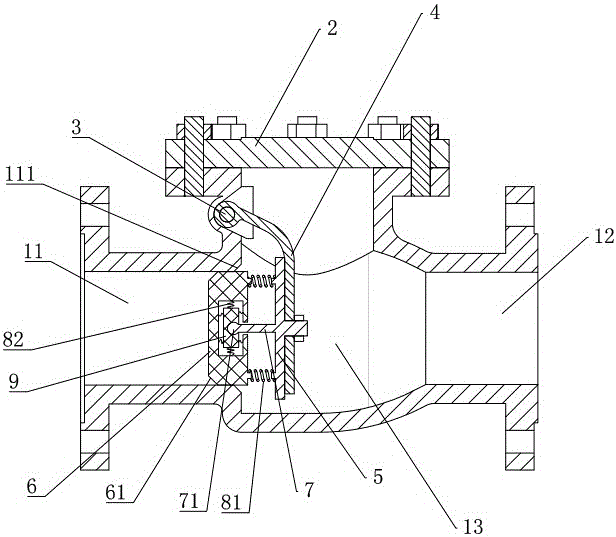

[0024] Embodiment, a kind of check valve, refer to the attached Figure 1-2 , the valve seat 1 is provided with an inlet channel 11 and an outlet channel 12, a valve cavity 13 is provided between the inlet channel 11 and the outlet channel 12, and a valve body with a flange is provided at the valve cavity 13. The valve neck, the valve neck is connected with the valve cover 2, the valve shaft 3 is hinged at the valve neck, the valve shaft 3 is pivotally connected with the rocker arm 4, and the valve plate 5 is fixed on the rocker arm 4;

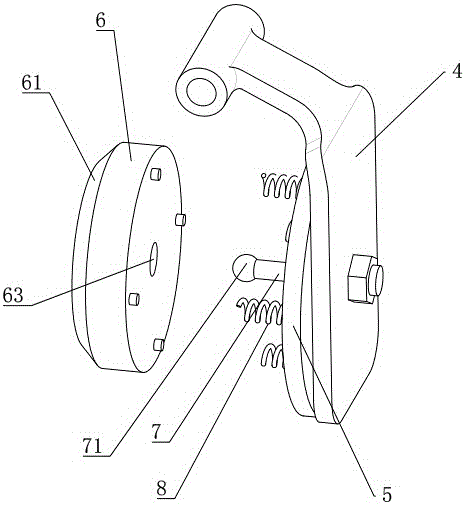

[0025] See attached image 3 and 4 combined with figure 2 , is an exploded view of the connection between the valve plate 5 and the elastic sealing body 6, the valve plate 5 is fixed with a support rod, and after the support rod passes through the relief hole 63 provided on the elastic sealing body 6, the floating block 9 is arranged in the floating cavity 62 , a ball head 71 is provided at the end of the support rod, and a ball seat cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com