A hydraulic fracturing perforation structure

A technology of hydraulic fracturing and pore structure, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc. It can solve the problem that the maximum stress direction of perforation is not consistent, effective network fractures cannot be formed, and a large number of effective fractures cannot be formed by perforation. problems such as mesh seams, to achieve a good effect of increasing production and improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

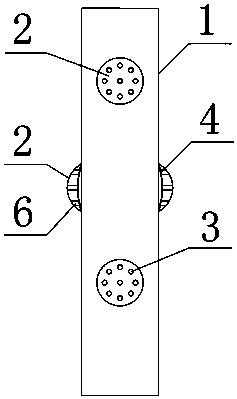

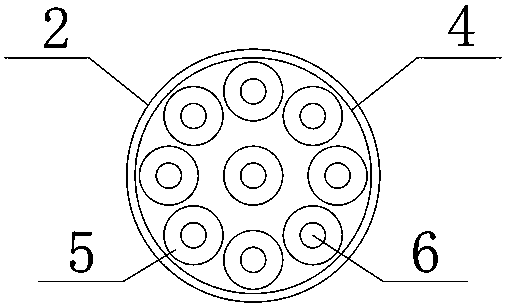

[0019] A hydraulic fracturing perforation structure comprising (see figure 1 ) Drilling wall 1, a spherical surface 2 is arranged on the drilling wall 1, and a perforation 3 is arranged on the spherical surface 2. A guide tube 6 is arranged inside the perforation 3, and one end of the guide tube 6 is connected with the pressure bearing plate 5, and the pressure bearing plate 5 is located on the bearing The inner side of the pressure surface 4, the pressure receiving surface 4 is fixed on the inner side of the spherical surface 2.

[0020] The perforations 3 are evenly arranged on the spherical surface 2, and the diameter of the perforations 3 is 8-10 mm.

[0021] The distance between the perforation 3 and the guide pipe 6 is 1-2 millimeters; ensure that the guide pipe 6 can be put into the perforation 3 smoothly.

[0022] The length of the guide tube 6 is 1-2 mm longer than the distance between the pressure bearing surface 4 and the spherical surface 2, so as to ensure that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com