Formwork mounting and support reinforcing system for collector well, elevator shaft and the like

A technology of elevator shaft and water collecting well, which is applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connection, and on-site preparation of building components, etc. and other problems to achieve the effect of ensuring construction quality, ensuring stability, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

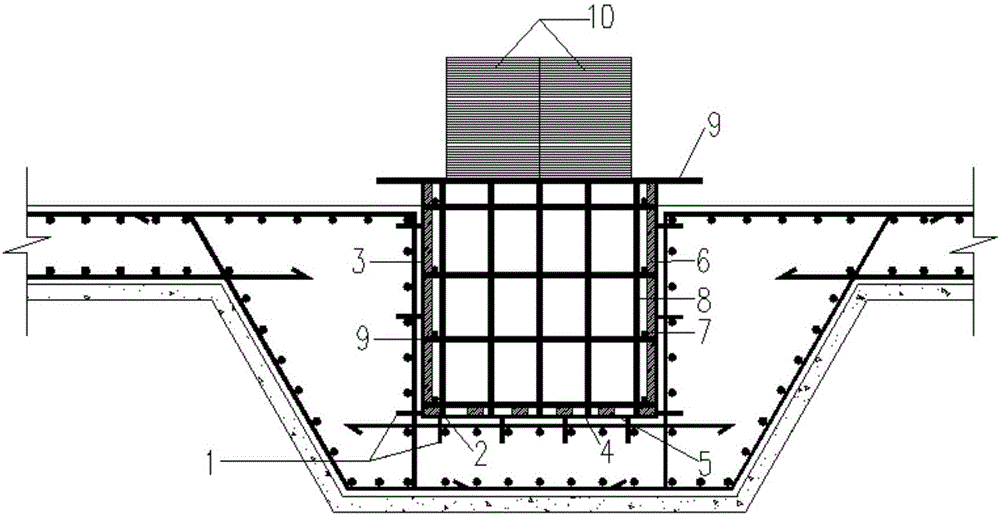

[0015] Such as figure 1 As shown, the present invention is a formwork installation and support reinforcement system for water collection wells, elevator shafts, etc. It is characterized in that: firstly, according to the plane positioning size and depth of the well, the steel bar 1 is fixed on the steel bar skeleton and the protective layer of the steel bar is controlled. The bottom formwork 2 and the side formwork 3 are erected on the protective layer reinforcement 1, and 4 air holes are opened in the bottom formwork 2 in the vertical and horizontal directions with a distance of 1.5m, and then the horizontal square wood 5 is laid on the On the bottom formwork 2, the vertical square wood stands on the side of the side formwork 3 as the back corrugation, and then the vertical pole 8 is matched with the vertical horizontal pole 7 and the horizontal horizontal pole 9 to fix the bottom formwork 2 and the side formwork 3 firmly, and the uppermost layer is horizontally horizontal Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com