Heat-insulated building structural slab

A building structure, heat insulation technology, applied in building components, building structures, buildings, etc., can solve the problems of unsatisfactory heat preservation, sound insulation, fire prevention, etc., low strength, high cost, etc., and achieve excellent structural mechanical properties and high strength , the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

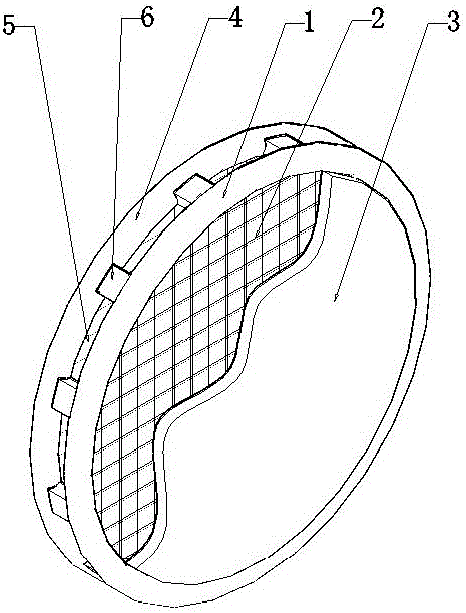

[0016] figure 1 , figure 2 In this method, at least two layers of ring-shaped arch members are used, namely: the inner layer ring-shaped arch member 1 and the outer layer ring-shaped arch member 4, to replace the columns and beams as load-bearing members in traditional buildings; The tensioned mesh connector 2 in the ring inner area of the arched member 1, and the tighter mesh connector 5 arranged in the ring inner area of the outer annular arched member 4, as a building wall or / and floor slab and filled with wall insulation material (not shown in the figure), and a decorative wallboard or floor 3 is arranged on the outside; between the two layers of ring-shaped arched components, the heat-insulating connecting material 6 is used to separate , forming a broken bridge structure; thereby forming a thermal insulation building structural panel;

[0017] The above-mentioned thermal insulation building structural panels can be combined and connected to form a modular building...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com