Textile with tick removal effect and manufacture method and application thereof

A technology for textiles and ticks, which is applied in the field of functional textiles and its preparation, can solve the problems of not yet having anti-tick functions, and achieve the effects of excellent anti-tick performance, good wearing performance, and high anti-tick performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

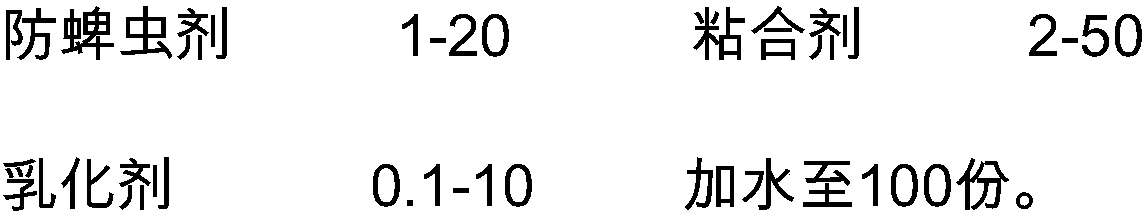

[0034] Prepare the anti-tick finishing solution according to the following ratio:

[0035]

[0036] Prepare the anti-tick finishing solution as follows:

[0037] Add citronella oil, artemisia annua oil, cedar essential oil and emulsifier in the chemical tank Stir evenly, then add water and stir quickly, and finally add the binder Stir evenly to obtain the anti-tick finishing solution.

[0038] Prepare textiles with anti-tick function as follows:

[0039] Dip the fabric with anti-tick finishing solution, with a nip rate of 70%-80%, then dry at 80-100°C (2-5 minutes), and then stretch at 150-155°C for 30-45 seconds to obtain the product . After testing by the Institute of Entomology of the Chinese Center for Disease Control and Prevention, the product of the present invention has a repellent rate of 98.5%.

Embodiment 2

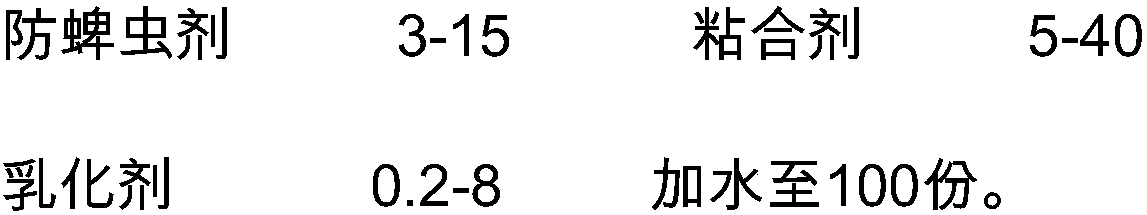

[0041] Prepare the anti-tick finishing solution according to the following ratio:

[0042]

[0043]

[0044] Prepare the anti-tick finishing solution as follows:

[0045] Add artemisia annua oil, salt pine seed oil and luohan asphalt oil and emulsifier in the chemical tank Stir evenly, then add water and stir quickly, and finally add the binder Stir evenly to obtain the anti-tick finishing solution.

[0046] Prepare textiles with anti-tick function as follows:

[0047] The fabric is sprayed with an anti-tick finishing solution with a rolling rate of 70%-80%, and then dried to obtain a product; the product of the present invention has been tested by the Institute of Entomology of the Chinese Center for Disease Control and Prevention to have a repellent rate of up to 98.0%.

Embodiment 3

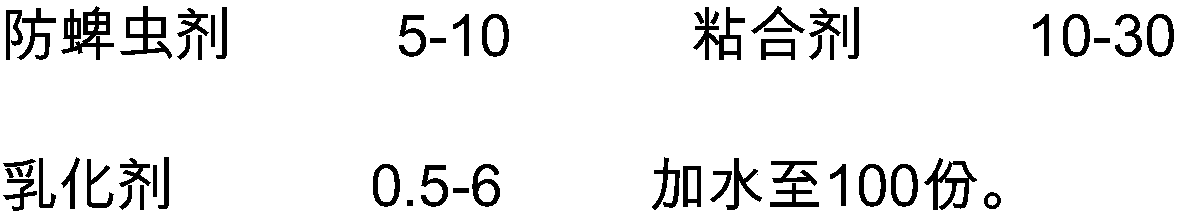

[0049] Prepare the anti-tick finishing solution according to the following ratio:

[0050]

[0051] Prepare the anti-tick finishing solution as follows:

[0052] Add citronella oil, artemisia annua oil and cedar essential oil and emulsifier in the chemical tank S-400, stir evenly, then add water and stir quickly, and finally add Low-temperature fixing agent SCJ-939, stir evenly to obtain anti-tick finishing solution.

[0053] Prepare textiles with anti-tick function as follows:

[0054] The invention adopts a padding process to process pure cotton bleached fabric (JC, 40sx40s, 110x100). Process flow: fabric → padding anti-tick solution (dipping rate 70%) → drying (80-100°C) → high temperature tentering (150-160°C × 30s) to obtain the product. After testing by the Institute of Entomology of the Chinese Center for Disease Control and Prevention, the product of the present invention has a repellent rate of 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com