Method for preparing iron oxide red from coal ash

A technology of iron oxide red and fly ash is applied in the field of environmental chemistry to achieve the effects of improving utilization rate, good separation effect and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

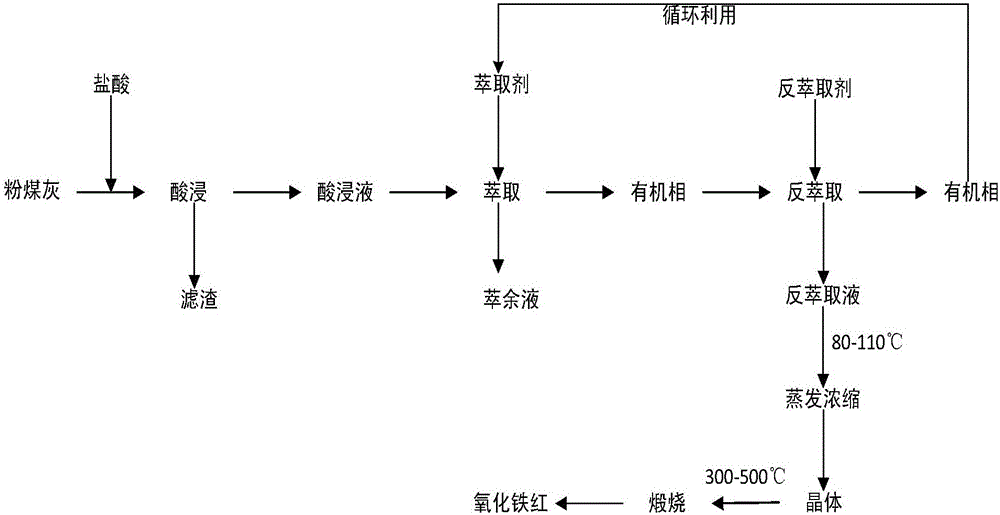

[0055] A kind of preparation method of iron oxide red, process flow chart sees figure 1 , and its specific preparation steps are as follows:

[0056] (1) Soak 1 mass part of fly ash in 1 mass part of 4mol / L hydrochloric acid solution for 5 hours, then remove the filter residue to obtain acid dipping solution.

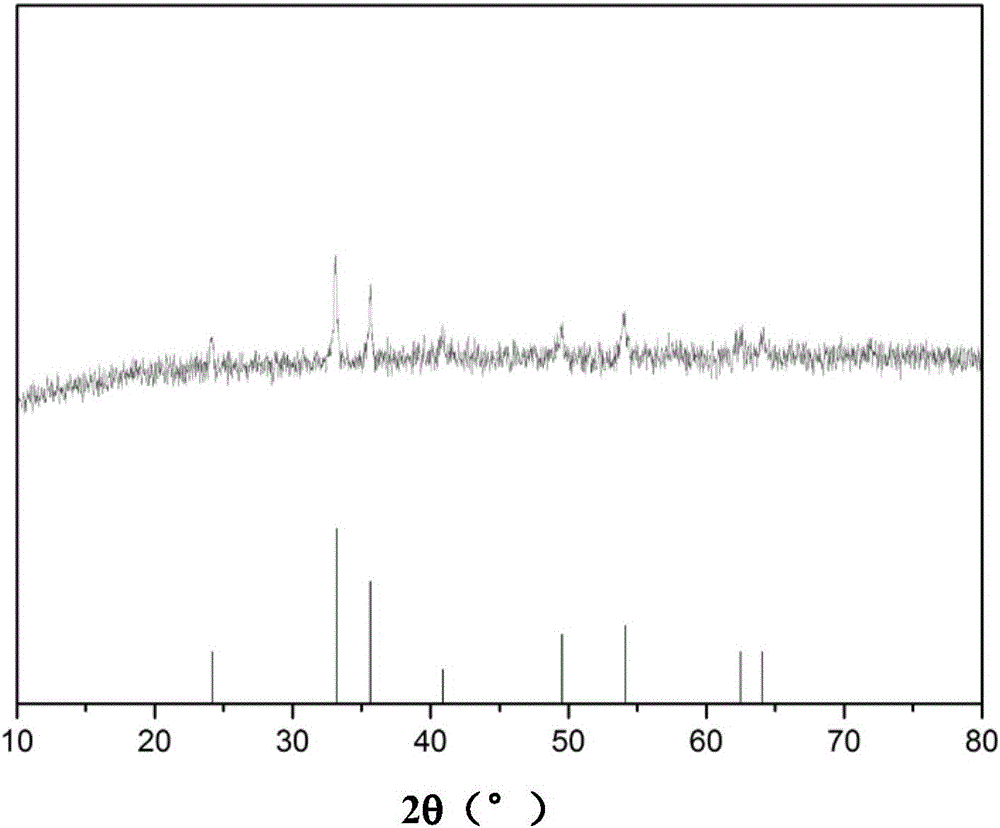

[0057] (2) The extraction organic phase of 1 volume part of N503+TBP+kerosene composition is placed in the extraction reactor and mixed with 1 volume part of the pickling solution, wherein the volume ratio of N503:TBP:kerosene is 2:1:2, extraction The volume ratio of the organic phase to the pickling solution is 1:2, then vibrate for 5 minutes, separate the phases and keep the extract.

[0058] (3) the oxalic acid solution of 1 volume part 0.75mol / L is placed in the extraction reactor as back extraction agent and 1 volume part extraction liquid in step (2) and mixes, and wherein the volume ratio of back extraction agent and extraction liquid is 1 : 1, then shake and c...

Embodiment 2

[0061] (1) Soak 1 mass part of fly ash in 1 mass part of 4mol / L hydrochloric acid solution for 5 hours, then remove the filter residue to obtain acid dipping solution.

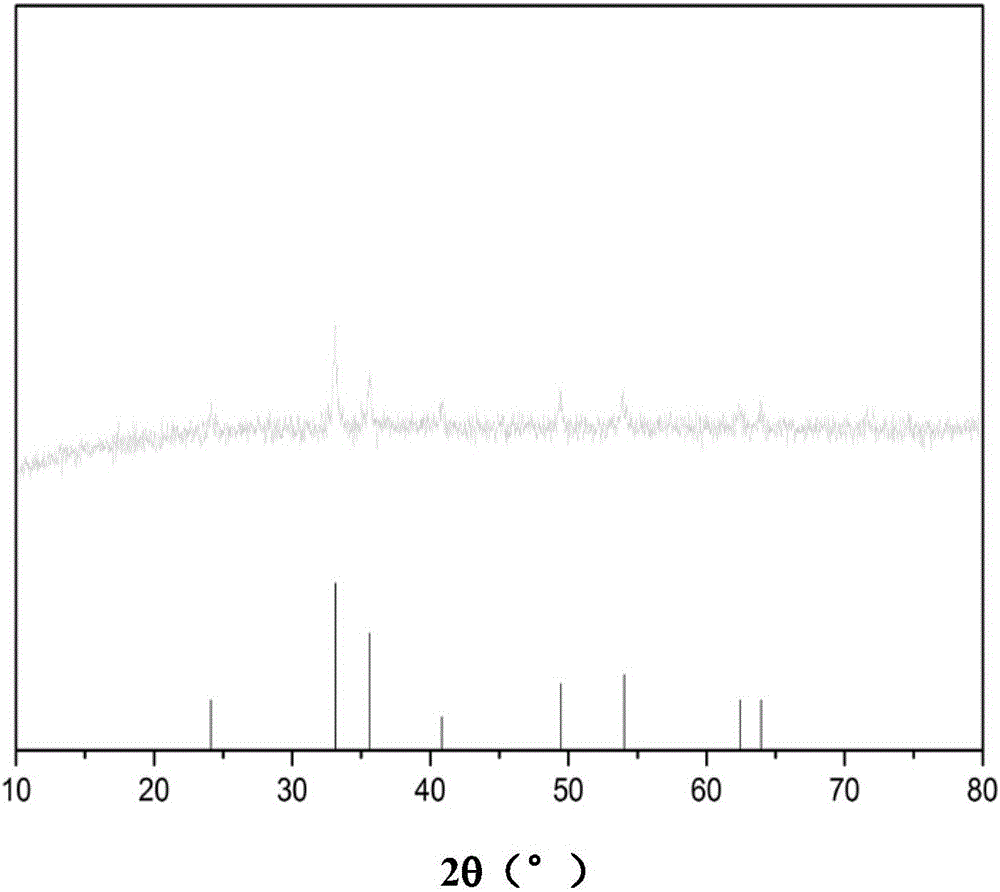

[0062] (2) The extraction organic phase of 1 volume part of N503+TBP+kerosene composition is placed in the extraction reactor and mixed with 1 volume part of the pickling solution, wherein the volume ratio of N503:TBP:kerosene is 2:1:2, extraction The volume ratio of the organic phase to the pickling solution is 1:1, then vibrate and contact for 5 minutes, then separate the phases at rest, and retain the extract.

[0063] (3) the oxalic acid solution of 1 volume part 0.75mol / L is placed in the extraction reactor as back extraction agent and 1 volume part extraction liquid in step (2) and mixes, and wherein the volume ratio of back extraction agent and extraction liquid is 1 : 1, then shake and contact for 4min, static phase separation, the unloaded organic phase after phase separation is recycled, and the stri...

Embodiment 3

[0066] (1) Soak 1 mass part of fly ash in 1 mass part of 4mol / L hydrochloric acid solution for 5 hours, then remove the filter residue to obtain acid dipping solution.

[0067] (2) The extraction organic phase of 1 volume part of N503+TBP+kerosene composition is placed in the extraction reactor and mixed with 1 volume part of the pickling solution, wherein the volume ratio of N503:TBP:kerosene is 2:1:2, extraction The volume ratio of the organic phase to the pickling solution is 3:1, then vibrate and contact for 5 minutes, then separate the phases at rest, and retain the extract.

[0068] (3) the oxalic acid solution of 1 volume part 0.75mol / L is placed in the extraction reactor as back extraction agent and 1 volume part extraction liquid in step (2) and mixes, and wherein the volume ratio of back extraction agent and extraction liquid is 1 : 1, then shake and contact for 4min, static phase separation, the unloaded organic phase after phase separation is recycled, and the stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com