Optical fiber screening, rewinding and whip preventing device

An anti-whiplash, optical fiber technology, applied in the field of optical fiber manufacturing, can solve the problems of optical fiber waste, optical fiber quality impact, increased labor and equipment costs, etc., to ensure quality, reasonable design, and eliminate optical fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

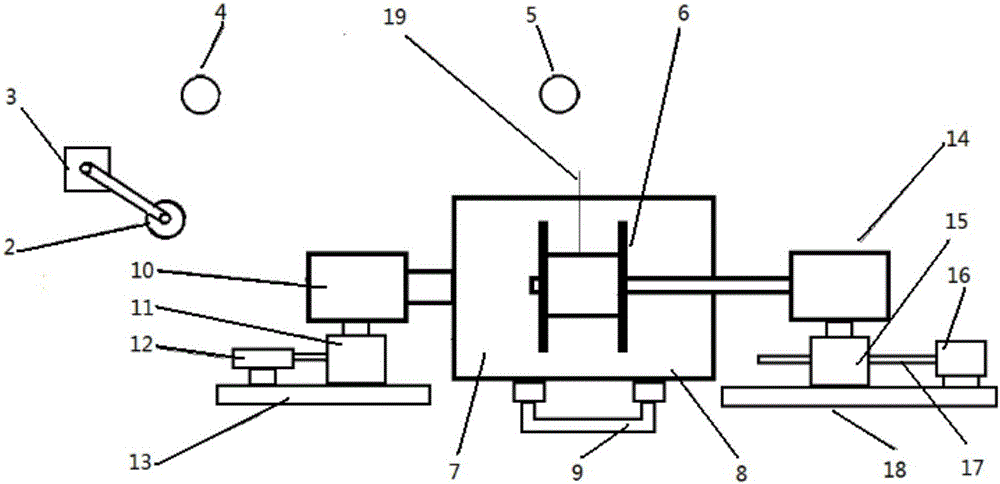

[0030] refer to figure 1 As shown, this embodiment discloses an optical fiber screening and rewinding anti-whiplash device. The specific structure of the device is as follows:

[0031] The optical fiber 1 enters the optical fiber screening and rewinding device from the end of the dancing wheel 2, the above-mentioned dancing wheel 2 is supported by a support rod, one end of the above-mentioned supporting rod is connected to the above-mentioned dancing wheel 2, the other end of the above-mentioned supporting rod is fixed, and the above-mentioned supporting rod The other end is provided with dancing wheel sensor 3, in fact, above-mentioned dancing wheel 2 is not a fixed state, when above-mentioned dancing wheel 2 has optical fiber to pass through (optical fiber 1 gives it an upward lifting force) when being in horizontal position, above-mentioned dancing wheel 2 When no optical fiber passes through, the position drops due to its own gravity.

[0032] The optical fiber 1 enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com